Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

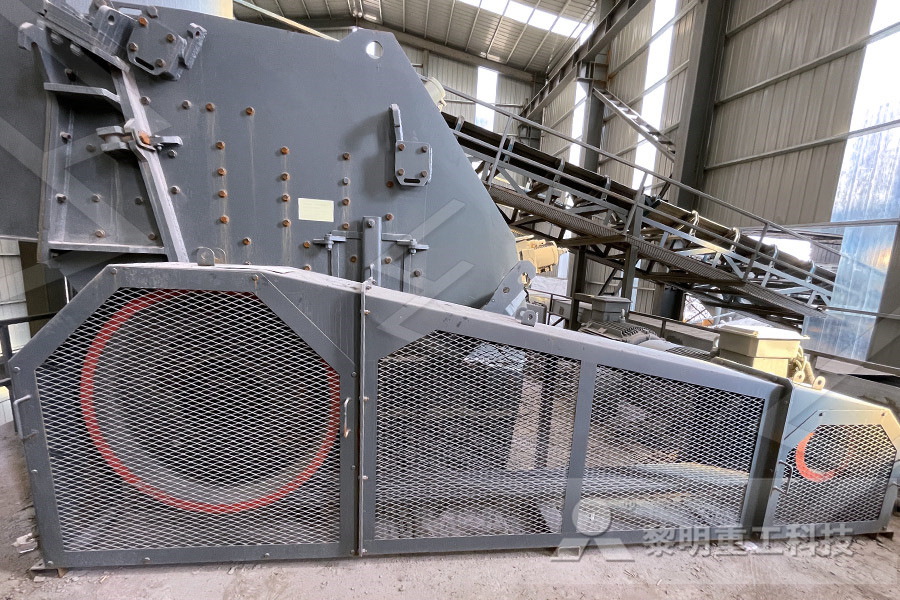

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

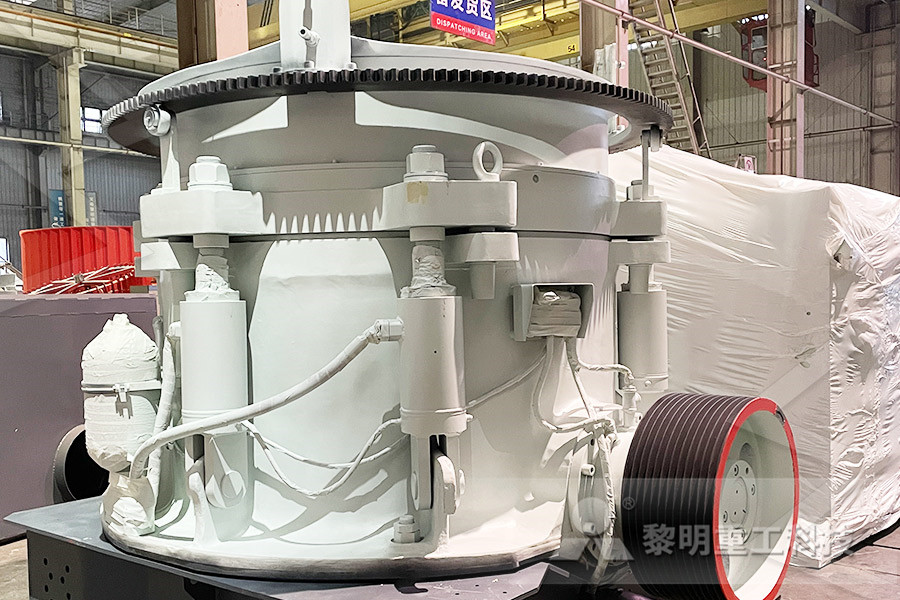

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millIn present cement plants, the new dry process cement rotary kiln is the most widely usedFrom quarry to bagging, we are committed to provide you equipment and spares for all stages of cement manufacturing like Crusher, Raw Mill, Preheater, Kiln, Cooler, Cement Mill, Vertical Mill Ball Mill, Silos, Packing PlantTypes Of Raw Mill In Cement Plant Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable Cement Raw Mill in Cement Plant for Cement Raw

Raw Mill,Raw Mill In Cement Plant hotcrusher

13 行 Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary Raw meal grinding is a vital link in the cement raw material preparation process After the cement raw material is crushed, it will be sent into the raw mill for further grinding until Raw Mill – Raw Mill In Cement Plant AGICO Cement This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw millRaw Mill In Cement Plant,Cement Making Plant

raw mill in cement plant system lacorneille

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials saving both space and energy while delivering outstanding performance >>Get Quotation Process filter trends in the cement industry Cement Lime GypsumCement raw material is a mixture of different minerals The mixture must contain a defined ratio of calcium oxide, quartz, aluminum oxide, and iron oxide as required for clinker production Calcium oxide is contained in various types of limestone but also in marl, shelly limestone, or chalkRaw mills for all requirements Gebr Pfeiffer Cement drytype ball mill is mainly used for grinding raw materials and clinker (finished products and raw materials) in cement plant, and also for grinding various ores and other grindable materials in metallurgy, chemical industry, electric power and Cement Ball Mill JXSC Machine

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable Cement raw material is a mixture of different minerals The mixture must contain a defined ratio of calcium oxide, quartz, aluminum oxide, and iron oxide as required for clinker production Calcium oxide is contained in various types of limestone but also in marl, shelly limestone, or chalkRaw mills for all requirements Gebr PfeifferThe ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials saving both space and energy while delivering outstanding performance >>Get Quotation Process filter trends in the cement industry Cement Lime Gypsumraw mill in cement plant system lacorneillegourmandefr

Parts Of Raw Mill In Cement Plant Sand Making Plant

Cement Grinding Mill In Cement Plant Raw Mill In Cement Plant,Cement Making Plant Its a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etcImpact Crusher CHAT ONLINE GET A QUOTE MoreWhat is raw mill in cement plant? A raw mill is the equipment used to grind raw materials into “rawmix” during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill which is a basic material for all types of construction, including Quick Answer: What Is Raw Mix Design? Ceramics SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALY

Operation Guide for Vertical Roller Mill in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcCement production equipment and technology is the advantage of my plants ,my plant the production of cement rotary kiln, cement mill can be used in 50 tons to 1500 tons/day of cement plant Feature: high production capability environmental friendly advanced technology Lower investment Easy maintenanceCement Production PlantCemet Production LineCement 2 天前 China cement mill catalog of High Efficient Dry Process Cement Ball Mill, Large Capacity Clinker Cement Grinding Mill provided by China manufacturer CITICHL HEAVY INDUSTRIES CO, LTD, page1 Cement Grinding Plant Fote Machinery(FTM) Aug 08, 2019 Cement ball mill is the key equipment in the cement grinding processBall mill type cement application dry grinding cement plant

Stacker and reclaimer systems for cement plants

Mill feed system Chemical characteristics of the materials to be handled Prehomogenisation Prehomogenisation is often necessary in the cement industry, in cases where the raw material chemical composition varies greatly Prehomogenisation is used primarily for the main components in cement production, ie limestone and clayThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw millRaw Mill In Cement Plant,Cement Making PlantThe ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials saving both space and energy while delivering outstanding performance >>Get Quotation Process filter trends in the cement industry Cement Lime Gypsumraw mill in cement plant system lacorneille

raw mill in cement plant animations sscafepl

grinding plant raw mill in cement plant Raw MillRaw Mill In Cement Plant AGICO Cement Raw Mill Raw meal grinding is a vital link in the cement raw material preparation process After the cement raw material is crushed it will be sent into the raw mill for further grinding until a certain degree of fineness is reached and then enter the clinker calcination processThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcOperation Guide for Vertical Roller Mill in Cement A Raw Mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill The Rawmilling stage of the process effectively defines the chemistry (and therefore physicalRaw Mill Classifier at Best Price in India

Cement Milll Separator Cyclone Air Separator in

Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s grinding efficiency The raw mix is fed into a circular storage unit called a raw mix storage Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grinding The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron oreManufacturing process Lafarge Cement, concrete Cement plants form a challenging environment for rotating equipment Significant amounts of silica dust occur as a byproduct of certain construction processes Over time this dust subjects rotating equipment, including Raw Mill fans, to high levels of erosion which ultimately reduces the plant’s output over timeRaw Mill Fan Upgrade Case Studies Howden

Grinding Mills Common Types

In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of 2 天前 China cement mill catalog of High Efficient Dry Process Cement Ball Mill, Large Capacity Clinker Cement Grinding Mill provided by China manufacturer CITICHL HEAVY INDUSTRIES CO, LTD, page1 Cement Grinding Plant Fote Machinery(FTM) Aug 08, 2019 Cement ball mill is the key equipment in the cement grinding processBall mill type cement application dry grinding cement