Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

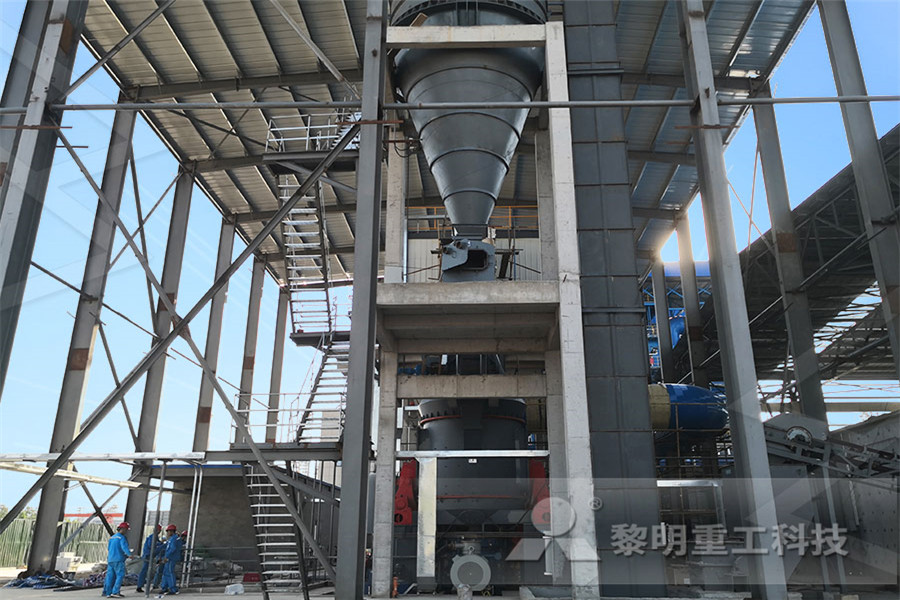

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Prove Of Critical Speed Of Ball Mill divinechannel

Prove Critical Speed Of A Ball Mill Milling Equipment prove critical speed of a ball mill A class of machinery and equipment that can be used to meet the production requirements of coarse grinding fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 mesh A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical Ball Mill Critical Speed 911 Metallurgistprove of critical speed equtaion in ball mill Ball mill critical speed formula derivationall mill critical speed m jun a ball mill critical speed actually ball rod ag or sag is the speed at which the formula derivation ends up as follow critical speed is ncee details calculator for ball mi read nowprove of critical speed equtaion in ball mill

Critical Speed Of Ball Mill Formula Derivation

Ball mill critical speed derivation Ball Mills Mine EngineerCom ball mill critical speed derivation,If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill The point where the mill becomes a centrifuge is called the Critical Speed, and dragThe second is air drag, whichA Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which The Formula derivation ends up as follow: Critical Speed is: Nc Get Price A Review of Rolling Element Bearing Vibration "Detection to aerospace, in equipment as diverse as paper mill rollers to ball mill critical speed derivation Pochiraju Industries Rose and Sullivan showed critical rotation speed N c, to reach the final stage, ie, centrifugal motion: (1) N c = 1 2π 2g D−2r where D is the inner diameter of a jar and r is the radius of balls All throughout, they used the critical rotation speed as the constant value for given conditions of ballmill Critical rotation speed for ballmilling ScienceDirect

formula calculates the critical speed of a ball mill

Ball Mill Critical Speed Mineral Processing Metallurgy A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell The speed of the mill was kept at 63% of the critical speed The face angle was varied from 90 to 111 degrees for the three types of configuration 1, 2 and 4, as shown in the figure Also, the height of the lifter bar in configuration 3 was changed to observe the trajectoryMill Critical Speed Calculation 911 MetallurgistCement ball mill critical speed formula ball mill critical speed mineral processing metall the critical speed of a rotating mill is the rpm at which a grinding medium will begin to centrifuge namely will start rotating with the mill and therefore cease to carry out useful work ball mills have been successfully run at speeds between and percent formula for critical speed of a ball mill Prominer

: Mill Critical Speed Determination

The mill critical speed will be calculated based on the diameter (above) less twice this shell liner width Mill Actual RPM: Enter the measured mill rotation in revolutions per minute Result #1: This mill would need to spin at RPM to be at 100% critical speed Four experiments were performed with a laboratory scale overflow ball mill Three were conducted to study the process and determine the parameters, and the last was for validation The internal dimensions of the mill are 4826 cm in length and 2286 cm in diameter The tests were performed at 70% of the critical speed and chargedNEW APPROACH TO BALL MILL MODELLING AS A The combination of those three changes would prove critical On Jan 16, Hoff, Captain, and graduate students Jack Davis and Oswaldo Guio confirmed that, after about six hours in the ball mixer, different salt mixtures and reaction conditions were able to trap and bind the nitrous oxide gas That was a major breakthroughChemists close in on greener method for making fertilizer

Debromination and Decomposition Mechanisms of Phenolic

Ballmilling experiments were carried out by using a planetary ball mill (YXQM2L, MITR Instrument Equipment Company, Changsha) A mixture of nonmetallic particles and iron powder (120 g in total) was placed in the grinding pot with agate balls (5–10 mm in diameter) The total weight of the balls was approximately 180 g SKF stainless steel deep groove ball bearings are manufactured to both withstand tough application requirements and to be the first choice when moisture, corrosive or abrasive materials are present SKF now offers an expanded assortment of stainless steel deep groove ball bearings in both metric and imperial sizes A wide vari SKF stainless steel deep groove ball bearingsComplete 45 ACP ammunition ballistics Chart Compare all 45 ACP ammunition manufacturers on one easy to read chart45 ACP Ballistics Chart Ballistics 101

Microcanner home page

Co2 content, when measured with a Zahm, not to exceed 27 (or you will run slowly) Higher IBU beers at high gravity with high Co2 can prove to run much slower than a low Co2 product COLD product is critical for speed Cleaned and dried compressed air at 80 PSI with quick disconnect and enough hose to reach the can line 6 SFCM @ 90 PSI maximum speed factors for use in deep groove ball bearings are specified They should not be lower than the speeds to be expected in a given application Please contact Klüber Lubrication for further assistance in this respect The following table contains the anticipated speed Special knowledge The element that rolls the bearing Lignocellulosic feedstock materials are the most abundant renewable bioresource material available on earth It is primarily composed of cellulose, hemicellulose, and lignin, which are strongly associated with each other Pretreatment processes are mainly involved in effective separation of these complex interlinked fractions and increase the accessibility of each individual component, thereby Recent updates on different methods of pretreatment of

9mm Luger Ammunition 9mm Ammo Cheaper Than Dirt

Cheaper Than Dirt! keeps a large selection of the best 9mm loads in stock because we know shooters across the country have come to rely on its versatility and dependability Take a ball nose for example, Output through Center will drive the toolpath generation to be output at the very center of the ball, so the code generated would always be the radius of the tool away from the part For those folks who want to drive your tool How to Set Up Your Tool Crib in SOLIDWORKS CAM