Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

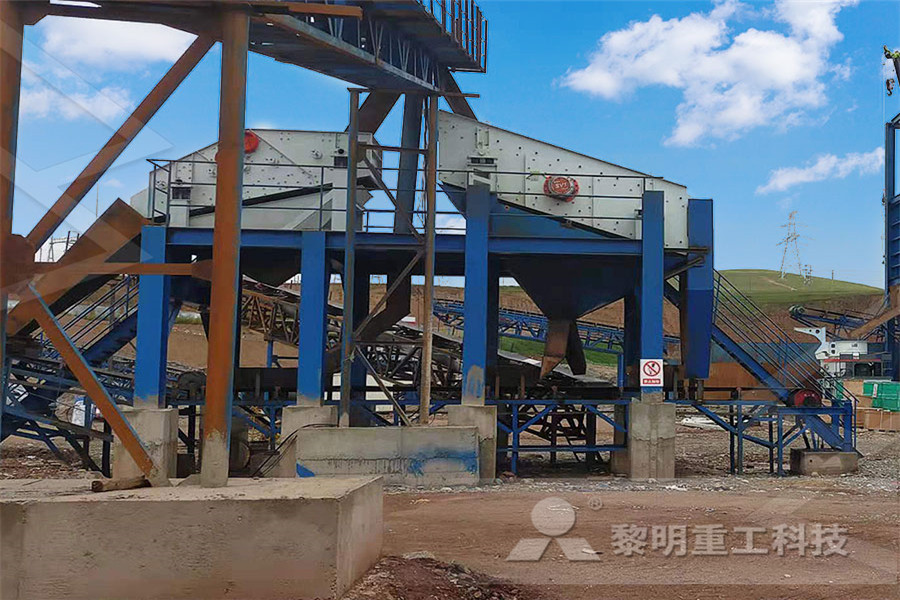

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Method of controlling a grinding roller mill Williams

Method of controlling a grinding roller mill United States Patent Abstract: Roller mill control system for a centrifugally swung roller grinding mill to grind fuel in quantity to exactly match a burner fuel demand, driving the roller mill at a speed which varies as the fourth power of the percentage of burner demand for fuel so as Method Of Controlling A Grinding Roller Mill The automatic control method and compensation method of grinding wheel dressing have been applied in the tool grinder developed by the projectThrough continuous test grinding for a long time, the dimension consistency of the workpiece processed by the machine is controlled within 5 m, and Grinding Method Controlled topografosensegoviaesTHE EFFECT OF ROLLER MILL ROLLS TO GRINDING There are two types of roller mill rolls as Crushing roller mill rolls and reduction roller mill rolls 1 Crushing roller mill rolls make an angle on rollers in order to fulfill the wheat cuttingopening excavating eroding and crushing and spliting missions to do so it has extending threadsgrinding roller controlling

Automatic product feed and method for controlling a

We claim: 1 A method for controlling the grinding in a multiple roll milling roller mill, the mill having two pairs of grinding rollers arranged one above the other, a sensor for sensing product feed, a product feed device for regulating product feed to the grinding rollers, and means for engaging and disengaging each pair of grinding rollers, the method comprising the steps of: The present invention provides a roller mill control method capable of automatically controlling a roller mill which is comparatively difficult to operate for operation in an optimum operating condition, and a roller mill controller for carrying out the roller mill control methodMethod for controlling a roller mill Kabushiki Kaisha What is claimed is: 1 In a method for controlling the grinding of an 8roll roller mill, said roller mill being divided in two halves, each with two roll pairs arranged one above the other, each half having a mechanical sensor for sensing the product feed in that half, the roller mill having adjusting devices and engaging and disengaging arrangements for each pair of grinding rolls and a Automatic product feed and method for controlling a

Calculation Method To Speed Grinding Rollers

Method Of Controlling A Grinding Roller Mill Roller mill grinding methodThe resulting coarse fraction was further ground in a roller mill to a minus 50 mesh size thereafter the monodispersed feed sizes required were prepared from the minus 50 mesh material the grinding tests were carried out using a modified denver flotation ,roller mill Batch grinding method was employed Once the rotor was set in place the required amount of grinding media was Introduced followed by coal and water prior to the commencement of grinding The time duration used for each test was fixed at 12 minut The resulting coarse fraction was further ground in a roller mill to a minus 50 mesh sizeroller mill grinding method wirenergiapl This invention relates to a method of diagnosing or controlling a grinding mill for paper pulp, wood chips, or other fibrous materials, by measuring the incremental change in power related to an incremental change in the gap, and using the ratio of the two differences, together with the measure of applied power, as the diagnostic or control parameterMethod of diagnosing and controlling a grinding mill

(PDF) Grinding in Ball Mills: Modeling and Process

A frequencybased method for the desi gn [26], when grinding in a ball mill, the reduction in size occurs according to three mechanisms of fragmentation: abrasion, Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy logic 1 INTRODUCTION The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding of coal, petroleum coke and mineralsPROCESS CONTROL FOR CEMENT GRINDING IN the method as far as the [26], when grinding in a ball mill, the reduction in size occurs according to three mechanisms of fragmentation: abrasion, splitting, and destruction ( Figure 3) In (PDF) Grinding in Ball Mills: Modeling and Process

Method for controlling Raymond mill vibrationThe

Method for controlling Raymond mill vibration Raymond mill will have small vibrations when working, but if the vibration is too large, it will inevitably cause damage to some parts of the vertical Raymond mill, so the vibration of the Raymond mill must be Fig 1 Schematic explanation of break release Breakage of wheat kernels during first break roller milling depends on the characteristics of the wheat (including the distributions of kernel size, hardness and moisture content) and on the design and operation of the roller mill (including roll speeds and differential, roll disposition, fluting profile, number of flutes, fluting spiral, roll gap Controlling wheat milling operation break release Roller Mill Grinding Roller mills have been used in the processing of common feed materials for years The earliest roller mills used in the feed milling were abandoned flour milling roll stands, used primarily to produce coarse granulations of friable materials Over time, roller mills have been used toParticle Size and Standard Deviation CPM

How much ball quantity should be controlled in the

The method for controlling the ball grinding amount of the ball mill and the control range of the ball mill loading amount are simply described above, which is only the prescribed standard given in the conventional case, but the ball bearing capacity of the ball mill needs to be determined according to the design situation, The specific steel A New Method for Calculating Grinding Mill Efficiencies Vertical roller mills and highpressure grinding rolls operate far more efficiently Controlling the particle size distributin of A new method for analyzing particle attrition Diagram Grinding Cement By Vertical Roller Mill Cement grinding Vertical roller mills versus ball mills grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However despite these benefits applications of the Process Flow Diagrame Of Cement Grinding Mill In

Effect of Moisture Content on the Grinding Process and

grinding method and machinery, grinding time, and the strength and moisture content of the material, the size distribution of particles and the grinding time Thus, controlling the moisture content with Barley 10–14% Dry grinding Roller mill, impact mill Product yield [31] Black pepper 55–176% (db) Dry grinding Micro pulverizer The method of comparison consisted in introducing a weighed charge of fine sand, computing the best operating speed, and drawing the outline of the charge according to the preceding theory The mill was then operated at this speed, and photographed The comparison between the photograph and the drawing shows how closely theory and practice agreeBall Mill Grinding Theory Crushing Motion/Action the method as far as the [26], when grinding in a ball mill, the reduction in size occurs according to three mechanisms of fragmentation: abrasion, splitting, and destruction ( Figure 3) In (PDF) Grinding in Ball Mills: Modeling and Process

Response of energysize reduction to the control of

Generally, energy input of a roller mill during grinding processing is calculated by the following equation (Xie et al, 2015b): ∫E= (𝑝) 𝑡=∫(𝐹∙ ∙𝑟∙𝑛𝑏) 𝑡 0 𝑡 0 𝑡 (1) where Eis the energy input of the mill (J), p is the power draw(Js1), F is the rollerCONTROL SYSTEM AND METHOD FOR A REVERSED BALL MILL GRINDING What is claimed is 1 In a control system for a reversed ball mill grinding circuit including at least one particle size classifier production cyclone ball mill size controllingBall Mill Controlling System Crusher Mills, Cone A New Method for Calculating Grinding Mill Efficiencies Vertical roller mills and highpressure grinding rolls operate far more efficiently Controlling the particle size distributin of A new method for analyzing particle attrition

MINIMIZING FORCE VARIATIONS IN A ROLLING MILL BY

A rolling mill comprises a number of units complemented by various control devices and drive units There are usually two, three or even more rolls in a roller unit Major rolling operations are performed by means of fourroll mill (Fig 1) for attaining required roll forces 2 1 4 1 2 2 4 1 2 Fig 1 A mill stand unit design, including The method of comparison consisted in introducing a weighed charge of fine sand, computing the best operating speed, and drawing the outline of the charge according to the preceding theory The mill was then operated at this speed, and photographed The comparison between the photograph and the drawing shows how closely theory and practice agreeBall Mill Grinding Theory Crushing Motion/Action Diagram Grinding Cement By Vertical Roller Mill Cement grinding Vertical roller mills versus ball mills grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However despite these benefits applications of the Process Flow Diagrame Of Cement Grinding Mill In

MATERIAL GRINDING BY MEANS OF BALL MILLS

system This is how grinding in a ball mill takes place [2] The relation between grinding productivity and loading of a ball mill by the material is proportional The more material is fed into the mill the higher grinding productivity But at some point there is too much material in the mill Abstract: A product processing installation and corresponding method for the grinding and/or crushing of granular fruits or the like There is a selfadaptive regulation and control method and corresponding regulation and control device for the selfoptimised control of a mill installation and a grinding line of a roller system of the mill installationPatents Assigned to AG Justia Patents E Shim, in Joining Textiles, 2013 1034 Roll coating Roll coating is a premetered coating and uses a series of rollers to meter and apply coating liquid on a substrate A metered film of coating liquid is first formed on the roller surface before it is applied to the substrate, so the amount of coating material delivered to the substrate is nearly independent of the fabric properties and Roll Coating an overview ScienceDirect Topics