Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

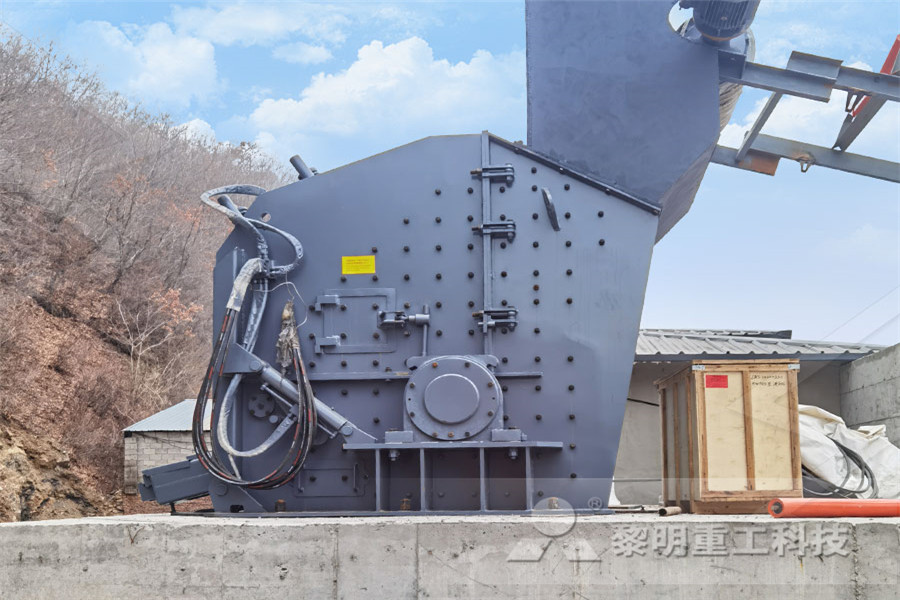

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Coal grinding systems Safety considerations PEC

Opening an inspection door on a coal grinding system can provide oxygen to smoldering, powdered coal and result in fires or explosions Use extreme caution when opening an inspection door Do not poke or disturb any coal accumulations if there is Coal Mill Safety Procedures Coal grinding systems safety considerations most rotary kilns use solid fuels as the main heat source to produce cement clinker a training program should be developed and extensive training for coal mill system operators provided on a regular basis safety considerations such as the prevention of fire or Read MoreSafety In Coal Grinding System feuerwehr Coal Grinding And Safety Issues tg lage schwimmen de Coal grinding systems safety considerationsoal grinding systems safety considerations, a training program should be developed and extensive training for coal mill system operators provided on a regular basis, any unusual temperatures must be reported immediately and steps taken to solve the problem cutting and welding around the coalsafety in coal grinding system netwerkoostkampbe

Coal Mill Safety

A coal grinding system with a milltobag house riser duct (marked with red line) that is very long Through it, unmitigated flame front propagation could reach a velocity too high for the installed protection to effectively protect the bag house This is a typical If any single component of the blend 20%, by weight has a VM higher than the weighted average then, this fuels VM is used to determine the level of risk TA: Technical Agenda Safety in Coal grinding Shops Update FEB 2007 7 Coal Shop Safety General Safety Rules Ignition Process Coal absorbs oxygen from atmosphere Heat Produced Heat Released Temperature increases and speeds up oxidation process (Inside the pile, the heat cannot be released) First three weeks of storage = maximum oxygen intakeCoal Mill Safety Combustion Coke (Fuel) Coal othersolid fuels importantrole cementmaking Although modern process control goodengineering can shoulddo much preventexplosions, some means remainnecessary lastresort Safety and explosion protection for coal grinding plant 豆丁网

COAL Penta Engineering Corporation

One of the techniques of a PHA used to identify hazards and operability problems is the HAZOP (Hazard and Operability) study that can be performed on both a new or operating coal grinding and firing system It is believed that the HAZOP is perhaps the most widely used methodology for identifying and mitigating hazards COAL HANDLING SAFETY Risks of unwanted combustion – potentially causing injury, damage and downtime – occur everywhere that coal is handled, processed or stored Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in the boilerCOAL HANDLING SAFETY AMETEK Land Asec Academy Safety Precaution in Coal handling Firing f Oxygenthe drying and conveying air in the pulverize contains sufficient 2 oxygen to support combustion of a coal dust cloud above Safety Precautions in Coal Handling and Firingdocx

In discussion Vincent Grosskopf, Coal Mill Safety

Vincent Grosskopf has more than 45 years of experience in bulk material handling, particularly regarding the safety of coal grinding systems As the founder of Coal Mill Safety, he acts as a consultant to those seeking to design and build safe greenfield coal grinding uumm al quwain grinding ball mill BKMF 2019 uumm al quwain grinding ball mill,Conveying Machine, Pelletizing Machine , Separation industry, safety equipments, transportation, construction and solar energy industry large coal shaking table in The United Arab Emirates Westcoal grinding plant safety in uae Prominer (Shanghai coal grinding safety coal Coal Dust Explosions in the Cement Industry coal safety requirements in the cement industry which accounts for a very small percentage of coal coal grinding high volatile coal milling safety Line Co

Coal Mill Safety Combustion Coke (Fuel)

COAL MILL OPERATION SAFETY ASPECTS 2 Coal Shop Safety 2 SOLID FUELS Coal Petroleum coke (sulfur % ) Delayed coke: the most common Non grindable fluid coke Shot coke (as impurity in delayed coke) Lignite Charcoal (moinha) 3 Coal Shop Safety FUEL DRYING GRINDING SYSTEM Flowsheet of Grinding Drying System Grinding Drying System Pulverized Coal Pulverized Coal COAL MILL OPERATION SAFETY ASPECTS Coal Shop Safety SOLID FUELS Coal Petroleum coke (sulfur % ) Delayed coke: the most common Non grindable fluid coke Shot coke (as impurity in delayed coke) Lignite Charcoal (moinha) 2 2 Coal Shop Safety FUEL DRYING GRINDING SYSTEM Raw Coal Dust Collector Feed Bin Hot gasesCoal Mill Safety Coke (Fuel) Coal Scribd Coal grinding and Firing Systems HAZOP Analysis A Process Hazard Analysis (PHA) is a key element of a Process Safety Management (PSM) program It analyzes potential risks to personnel operating in an industrial environment A PHA is a thorough detailed systematic approach to finding potential hazards in Coal grinding and Firing Systems HAZOP Analysis

Coal grinding Christian Pfeiffer

Coal grinding Safety in all applications Whether in cement works, steel mills or power plants, whether direct or indirect firing: Our ATEXcertified coal grinding plants have proven themselves internationally in all areas of application We also develop customtailored concepts for closeddown ball mills in the fine coal bins The grinding area is considered as the most critical one at cement plants with regards to dust explosion hazards The following cursory analysis explains how the five conditions for dust explosions are given in coal grinding plants: 1) Combustible dust: Coal 2) Dispersion: Coal dust is dispersed into the pulveriser, classifier,Engineered Explosion safety concepts for coal grinding The good news is that safety injuries have drastically come down over the past 40 years Since 2007 alone, the rate of injuries has dropped from 43 to 26 for every 100 employees MCR Safety is doing our part by constantly innovating safety gear that matches the needs of coal minersCoal Mining MCR Safety

Coal Mills for Cement Plants Loesche

Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirements Vincent Grosskopf has more than 45 years of experience in bulk material handling, particularly regarding the safety of coal grinding systems As the founder of Coal Mill Safety, he acts as a consultant to those seeking to design and build safe greenfield coal grinding In discussion Vincent Grosskopf, Coal Mill SafetyCoal grinding Safety in all applications Whether in cement works, steel mills or power plants, whether direct or indirect firing: Our ATEXcertified coal grinding plants have proven themselves internationally in all areas of application We also develop customtailored concepts for closeddown ball mills in Coal grinding Christian Pfeiffer

Coal grinding and Firing Systems HAZOP Analysis

Coal grinding and Firing Systems HAZOP Analysis A Process Hazard Analysis (PHA) is a key element of a Process Safety Management (PSM) program It analyzes potential risks to personnel operating in an industrial environment A PHA is a thorough detailed systematic approach to finding potential hazards in COAL MILL OPERATION SAFETY ASPECTS 2 Coal Shop Safety 2 SOLID FUELS Coal Petroleum coke (sulfur % ) Delayed coke: the most common Non grindable fluid coke Shot coke (as impurity in delayed coke) Lignite Charcoal (moinha) 3 Coal Shop Safety FUEL DRYING GRINDING SYSTEM Flowsheet of Grinding Drying System Grinding Drying System Pulverized Coal Pulverized Coal Coal Mill Safety Combustion Coke (Fuel)Preparation of Coal for Analysis By FG Walthall and SL Fleming, II Abstract Bulk quantities of coal weighing 3 to 15 kg are individually reduced to approximately 150 m m (100 mesh) by comminution procedures that minimize contamination by grinding surfaces or by other samplesUSGS Bulletin 1823 Preparation of Coal for Analysis

COAL PETROGRAPHIC LABORATORY PROCEDURES AND

Coal is the major rock type processed in the laboratory Occasionally, other rocks associated with coal beds are prepared (eg, claystone, shale, limestone, sandstone) Peat and soil samples are also periodically processed and analyzed When coal is received as a bulk sample in the laboratory, it is usually in one of two forms: 1) Loesche coal grinding mills are distinguished by other characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations: • Pressure shock resistance up to 35 bar (gauge) • Horizontal grinding table with segmented grinding track andLOESCHEMILLS Services for coal mill operations We’re a world leader in coal pulverizing and boiler mill operations for horizontal and vertical boiler mills—committed to highefficiency performance, reduced maintenance costs, and longer time between outagesBoiler Mill and Coal Pulverizer Performance GE

43 Hazard Identification, Risk Assessment and Risk

occupational safety hazard in steel mills Grinding and Cutting Activities, Locate machinetools at a safe distance from other work areas Conduct regular inspection and repair of machinetools, in particular protective shields and safety devices / equipment, PPE Rolling Processes and Activities Safety Issues While many people use coaltar hair dyes, FDA is aware of the following problems: Eye injuries: Hair dyes have caused eye injuries, including blindness, when used in Hair Dyes FDA