Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

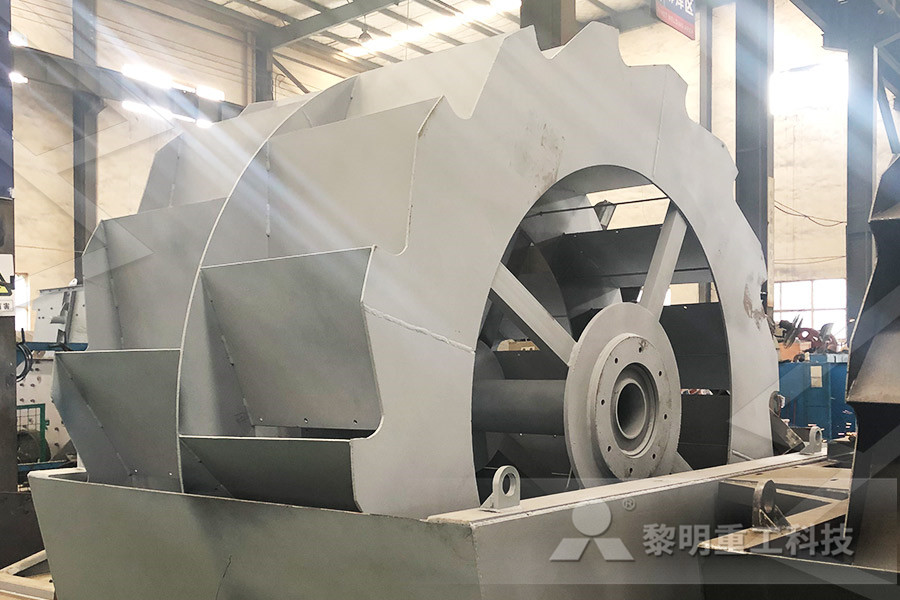

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

zinc ore concentrating

Zinc processing: Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn Inquire Now; A Study of the Concentration of a CopperZinc Ore Dodd, Kenneth L M,concentration of the zinc ore 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon Copper ore beneficiation plant Iron Ore Beneficiation Plant 20TPH vertical mill for limestone desulfurization in power plant 325mesh calcium carbonate production line concentration of the zinc ore ProductsThe zinc content of mined ore is usually between 3 and 10 percent Almost all ores contain the lead sulfide mineral galena and small quantities of cadmium sulfide Chalcopyrite, and copperiron sulfide, is often present The most common gangue constituents are calcite, dolomite, and quartzZinc processing Ores Britannica

Lead and Zinc Energy

6122 Lead and Zinc Ore Concentration If the mineral veins separate from the rock cleanly, then processing workers can concentrate the ore by taking advantage of the greater weight mineral compared to the rock Jigging separates coarse lumps In this process, the crushed ore is agitated or shaken in water with a verticalFlotation separation and recovery of lead and zinc concentrates from ores containing galena (PbS) and sphalerite (ZnS) is well established and generally achieved quite effectivelyLeadZinc ores Danafloatthe pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentrations can be 5070%, and the sulfur content of sulfidic ores is in the range of 1520% Zinc concentration is in the range of 4060%, with sulfur content in sulfidic ores in the range of 2634%LEAD ZINC EXTRACTION PROCESSES

Manual of Procedure for Chemical and Instrumental Analysis of

The chemistry of rock/ore is the key to understand the concentration of elements and presence of other associated elements There is no doubt that chemical analysis 310 DETERMINATION OF OXIDISED ZINC IN ZINC ORE, ZINC CONCENTRATE OTHER BENEFICIATED FRACTION 176 311 DETERMINATION OF OXIDISED LEAD IN LEAD ORE, LEAD CONCENTRATE OTHER concentration of the zinc ore 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon Copper ore beneficiation plant Iron Ore Beneficiation Plant 20TPH vertical mill for limestone desulfurization in power plant 325mesh calcium carbonate production line concentration of the zinc ore ProductsZinc processing: Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn Inquire Now; A Study of the Concentration of a CopperZinc Ore Dodd, Kenneth L M,zinc ore concentrating

Lead and Zinc Energy

6122 Lead and Zinc Ore Concentration If the mineral veins separate from the rock cleanly, then processing workers can concentrate the ore by taking advantage of the greater weight mineral compared to the rock Jigging separates coarse lumps In this process, the crushed ore is agitated or shaken in water with a verticalA copperzinc ore was fed to an integrated mineral processing system at the rate of 250 the concentration of germanium in these plants was in parts per billion (ppb) levels Commercially, germanium is typically obtained from flue dusts of smelters processing zinc or lead–zinc–copper ores It can also be recovered from the byproducts of Zinc Ore an overview ScienceDirect TopicsAug 07, 2020 Underground mining of zinc ores is less profitable Today, the openpit is the most common and affordable method But, the demand and quantity of zinc metal consumption is growing and contributes to the development of modern methods of developing offshore and oceanic deposits Beneficiation and concentration up to 62% ZnZinc Production CycleFrom the Ore to Zn Metal Metallurgy

Zinc Ore an overview ScienceDirect Topics

Gold recovery from copper– zinc ores is usually higher than that obtained from either a lead–zinc or copper–lead–zinc ore This is attributed to two main factors When selecting a reagent scheme for treatment of copper–zinc ores, there are more choices than for the other ore types, which can lead to the selection of a reagent scheme which is more favourable for gold flotationThe established leadzinc ore flotation processing scheme is to add zinc sulphate (ZnSO4) to the grind to control metal ion activation (sphalerite depression) Often metabisulphide or other sulphidation chemicals are added with the zinc sulphate for iron sulphide mineral depressionLeadZinc ores DanafloatZinc ores contain 515% zinc To concentrate the ore, it is first crushed and then ground to enable optimal separation from the other minerals Typically, a zinc concentrate contains about 55% of zinc with some copper, lead and iron Zinc concentration is usually done at the mine site to keep transport costs to smelters as low as possible Zinc Zinc: smelting, producing and classificationMetalpedia

Manual of Procedure for Chemical and Instrumental Analysis of

The chemistry of rock/ore is the key to understand the concentration of elements and presence of other associated elements There is no doubt that chemical analysis 310 DETERMINATION OF OXIDISED ZINC IN ZINC ORE, ZINC CONCENTRATE OTHER BENEFICIATED FRACTION 176 311 DETERMINATION OF OXIDISED LEAD IN LEAD ORE, LEAD CONCENTRATE OTHER Calamine is a historic name for an ore of zincThe name calamine was derived from lapis calaminaris, a Latin corruption of Greek cadmia (καδμία), the old name for zinc ores in generalThe name of the Belgian town of Kelmis, La Calamine in French, which was home to a zinc mine, comes from thisIn the 18th and 19th centuries large ore mines could be found near the German village of Calamine (mineral) WikipediaCopper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors As in all mining operations, the ore must usually be beneficiated (concentrated)Copper extraction Wikipedia

Process Plant Design Considerations for High Silver Gold Ores

Mar 02, 2016 Process Plant Design Considerations for High Silver Gold Ores Published on March 2, 2016 March 2, 2016 • 54 Likes • 6 CommentsThe value of crude ore by perfect concentration is then $1146 for the lead concentrate and $1118 for the zinc, or a total of $2264 per ton of crude ore Zinc processing Ores Britannica The most common method for accomplishing this concentration is to isolate the sulfide mineral from the impure constituents, or gangue, by flotation separatiolead and zinc ore concentration mill process chartCopper Ore Concentration Plant, Flotation Plant, Mining Copper mining equipmentProcess Equipment The copper lead zinc ore processing plants including the following equipment:for example,crusher,ball mill,flotation,vibrating screen,agitation tank,thickener,hydrocyclone and so oncopper mining concentration plants ore mill

zinc ore concentrating

Zinc processing: Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn Inquire Now; A Study of the Concentration of a CopperZinc Ore Dodd, Kenneth L M,concentration of the zinc ore 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon Copper ore beneficiation plant Iron Ore Beneficiation Plant 20TPH vertical mill for limestone desulfurization in power plant 325mesh calcium carbonate production line concentration of the zinc ore ProductsZinc processing Zinc processing Ores: Zinc ores are widely distributed throughout the world, although more than 40 percent of the world’s output originates in North America and Australia The common zinccontaining minerals are the zinc sulfide known as zinc blende or sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S], and a zinc carbonate known as calamine Zinc processing Ores Britannica

Electrolytic Zinc Metallurgist Mineral Processing Engineer

Nov 08, 2020 The power consumption for the latter plant is practically independent of the grade of ore treated, and it is virtually 4000 kwhr per ton of zinc output regardless as to whether that zinc is made from 60per cent, zinc concentrates or from 25per cent, zinc oresMar 30, 2020 Zinc ore is no longer mined in Germany today, and the zinc concentrations in the deposits are too low for costeffective zinc extraction The raw material for zinc extraction has therefore traveled a long way, for example, from Australia mostly by ship before it is processed into zinc History, Deposits, and Production of ZincThe chemistry of rock/ore is the key to understand the concentration of elements and presence of other associated elements There is no doubt that chemical analysis 310 DETERMINATION OF OXIDISED ZINC IN ZINC ORE, ZINC CONCENTRATE OTHER BENEFICIATED FRACTION 176 311 DETERMINATION OF OXIDISED LEAD IN LEAD ORE, LEAD CONCENTRATE OTHER Manual of Procedure for Chemical and Instrumental Analysis of

How to Process Copper Lead Zinc Ore with Gold and Silver

Apr 27, 2016 Flotation Plant A complex sulphide ore of this type requires a high degree of selectivity in the flotation process The lead and copper must be removed in bulk as a mixed concentrate and then the zinc floated as a separate concentrate because of marketing requirementsManganese Ore Concentration Refining Plant Lead zinc ore concentration plant how it works metallurgy lead smelting wikipedia, the free encyclopedia plants for the production of lead are generally referred to as lead smelters concentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite zinc ore concentration plant FreiluftGastronomie2 Leadzinc oxide ore In the leadzinc oxide ore, lead is mainly present in the state of leucite and lead bismuth, and zinc is mostly present in the state of smithsonite and willemite Oxidized ore is gradually formed by the action of longterm weathering and groundwater containing carbonateLead Zinc Mining Process Equipment Flow Cases JXSC

Copper extraction Wikipedia

Copper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors As in all mining operations, the ore must usually be beneficiated (concentrated)Copper Ore Concentration Plant, Flotation Plant, Mining Copper mining equipmentProcess Equipment The copper lead zinc ore processing plants including the following equipment:for example,crusher,ball mill,flotation,vibrating screen,agitation tank,thickener,hydrocyclone and so oncopper mining concentration plants ore millMar 25, 2021 Effect of iron in zinc silicate concentrate on leaching Feb 01 2009 0183 32 In those zinc leaching facilities integrated with ore concentration plants such as Votorantim Metais in Brazil the overall zinc recovery could be significantly increased by more than 8 when it is possible to increase the iron content in the flotation concentrate Download Download fullsize image Fig 13 Zinc mass zinc ore concentration plant

Leadzincsilver Ore Concentration Practice at the Lead

The LeadtZinc Concentrator at Mount lsa treats all the leadzincsilver ore from the Mount Isa Mine and some of the ore from the Hilton Mine This concentrator was commissioned in June 1966 and total leadzincsilver ore treatment was transferred from the Mount rsa’s original No 1 Concentrator in May 1967 Plant capacity is around 5 x 106 t/yFeb 09, 2018 At Mercadel, Santander, Spain, there is a magneticseparation plant treating oxidized zinc ores The ores carry calamine in a gangue of limestone and limonite, and assay from 12 to 30 per cent zinc The object of the treatment is to raise the zinc content to 50 per centElectromagnetic Separation of Copper Iron Sulphides