Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

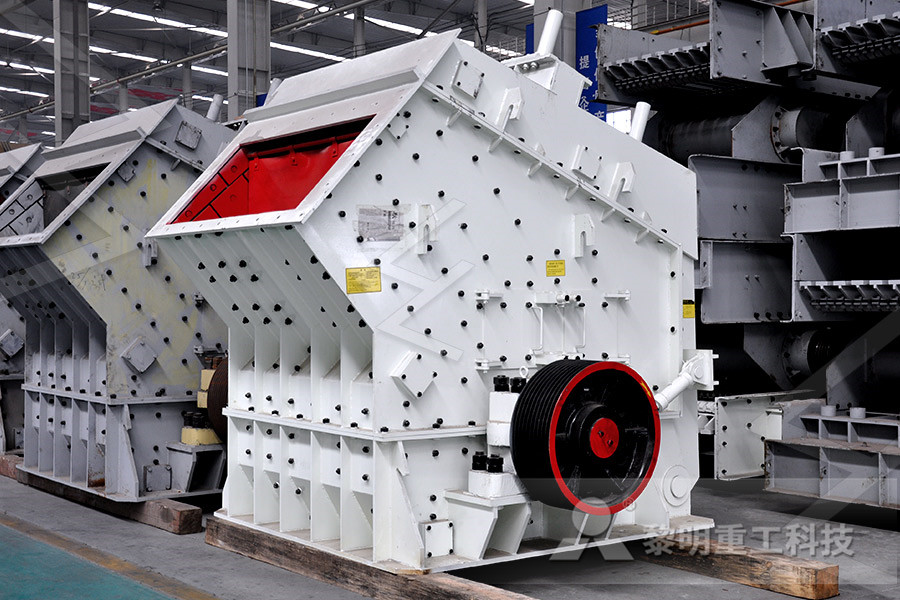

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Review on vertical roller mill in cement industry its

Jan 06, 2021 The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier Material is ground till desired Blaine is achieved and then final product is stored in concrete silos for further blending In silos cement is stored separately according to their grades so that mixing doesn't happen,,,Vertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product rangeVertical Roller Mills Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulatorsVertical Roller Mill In Cement Industry

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Because the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power, metallurgy, chemical industry, metal, and nonmetal ore industry is also well usedMar 09, 2021 Vertical Roller Mill in Cement End Milling Application Problem Analysis From:未知 Date: 15:37 Vertical roller mill application in the milling aspect well after cement has not reached the mill, which is developing rapidly and widely applied, but has evolved to the stage of practical application By vertical roller mill as final cement grinding not only have higher demands Vertical Roller Mill in Cement End Milling Application Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical roller mill for raw Application p rocess materials

Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expectedWhen grinding cement products, a grinding system composed of a roller press or an external circulation vertical mill + a powder concentrator + a tube mill is generally selectedCement Grinding Machine Selection: Vertical Roller Mill VS Feb 15, 2021 Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker These mills offer a high throughput rate and high quality final productRoller Mill Components – Cement Americas

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millVertical Cement Mill Cement Clinker Grinding Equipment Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Cement Grinding Machine Selection: Vertical Roller Mill VS

Vertical Roller Mill in Cement End Milling Application

Mar 09, 2021 Vertical Roller Mill in Cement End Milling Application Problem Analysis From:未知 Date: 15:37 Vertical roller mill application in the milling aspect well after cement has not reached the mill, which is developing rapidly and widely applied, but has evolved to the stage of practical application By vertical roller mill as final cement grinding not only have higher demands cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , cement grinding 2 %Cement grinding Vertical roller mills versus ball millsWonder Cement belongs to a family company based in Udaipur, India, which – apart from other businesses – is active in the cement industry As Gebr Pfeiffer already supplied 4 mills of the type MPS for raw material and pet coke grinding, the customer has now decided to use a vertical roller mill also for cement grindingMVR vertical roller mill for cement grinding

The OK™ mill the most reliable and efficient mill for

Jun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material griVertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

loesche Vertical Mill LM 563wmv YouTube

Nov 16, 2011 Process in vertical raw millVertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/dVertical Roller Mill for Cement Raw Material SINOMALY2 Reducing the power consumption of cement clinker preparation effectively According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and Cement Vertical Roller Mill greatwallcorporation

Vertical Roller Mill for Cement, Clinker, Slag, etc

Aug 10, 2018 Vertical Roller Mill for Cement, Clinker, Slag, etc From:未知 Date: 10:28 Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag The cement vertical roller mill equipment is used for maintenance and repair reasons, phenomena, required working hours, downtime, construction personnel and number of people, etc, and then statistical analysis, to determine the items to reduce maintenance operations, select the appropriate repair cycle and Check the cycle, select or revise the inspection items and inspection standards Cement vertical roller mill maintenance and maintenance cycleVertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millVertical Cement Mill Cement Clinker Grinding Equipment

Cement Vertical Mill

The cement vertical roller mill is one of the most important cement equipment It is the key grinding machine of materials being crushed The cement grinding mill plays a vital role in cement production line and cement production process Cement mill is widely used in cement, silicate products, new building materials, refractory materials 2 Reducing the power consumption of cement clinker preparation effectively According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and Cement Vertical Roller Mill greatwallcorporationVertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/dVertical Roller Mill for Cement Raw Material SINOMALY

Vertical Roller Mill for Cement, Clinker, Slag, etc

Aug 10, 2018 Vertical Roller Mill for Cement, Clinker, Slag, etc From:未知 Date: 10:28 Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For Mar 13, 2019 Thailand: Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone The cement producer previously ordered a LM 563+3 CS mill from Loesche for its Ta Luang cement plant in 2014vertical roller mill Cement industry news from Global Cement

vertical roller mill for cement

Largest vertical roller cement mill Guinness World Records The largest vertical roller cement mill is the OK816™ vertical mill, with a grinding table diameter of 808 m (26 ft 6 in) and roller diameter of 264 m (8 ft 7 in), achieved by Shah Cement Industries Ltd (Bangladesh), located in Dhaka, Bangladesh, on 6 September 2018get priceOverview of all of our mills Mills for grinding cement, coal, or minerals: Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products Our mills are as varied as the requirements of our customers Ball mills, vertical mills, compact mills, jet mills or roller mills? Our employees are experts Overview of our mills Christian PfeifferA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

Cement mills and raw mills for high throughput rates

Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills Alloy cast iron as per DIN 1695, hardfaced cast iron or composite materials with highchromium inserts in ductile base materials: the grinding elements designed by Pfeiffer are made of high Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of Vertical roller mill WikipediaThe differential pressure of the vertical roller mill is generally controlled at 5000~7000Pa to ensure the proper air volume The change of the pressure difference within the mill is mainly affected by the feed amount when other conditions are constant Therefore, the feed amount should be stabilized Vibration of Verticle Roller Millhow to improve grinding efficiency of vertical roller mill

Vertical Roller Mill for Cement Raw Material SINOMALY

As a professional manufacturer of vertical raw mill, SINOMALY has mature experience to produce raw mill with various specifications Finite element analysis methods are employed on key components to ensure the accuracy and quality of the products