Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

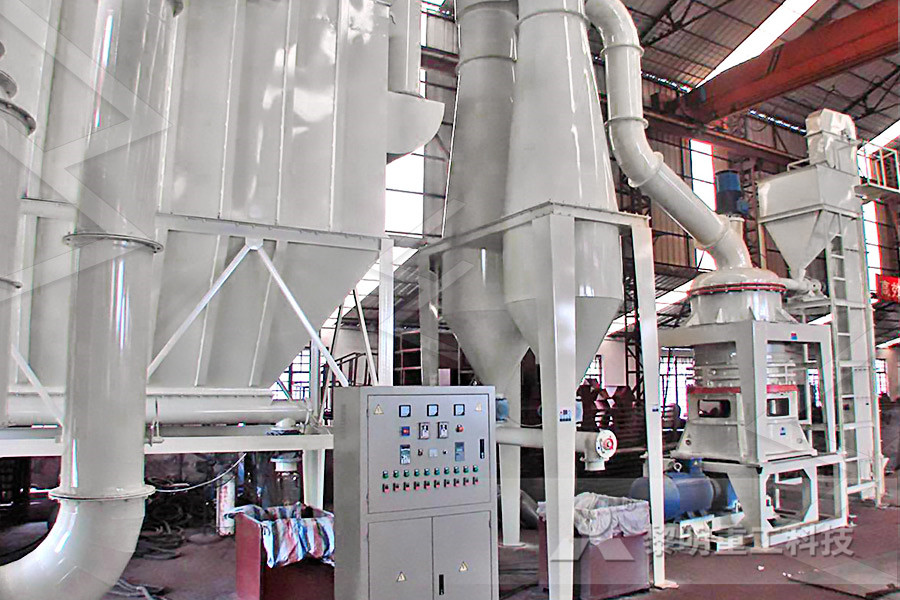

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Machine Tool Spindles Datasheets Engineering360

Find supplier datasheets for Machine Tool Spindles on GlobalSpec Machine tool spindles are rotating components used to hold and drive cutting tools or workpieces on lathes, milling machines and other machine toolsABTech ’s high precision air bearing spindles provide the ultimate performance utilizing a proven and robust design High stiffness, load capacity and very low error motion make these spindles ideal for precision machining, grinding, single point diamond turning, and high precision scanningMetric Machine Tool Spindles Engineering360 GlobalSpecFind Machine Tool Spindle Bearings related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Machine Tool Spindle Bearings informationMachine Tool Spindle Bearings GlobalSpec

Machine Tool Spindles Data Sheets from HSD SpA

122 rows Machine tool spindles are rotating components used to hold and drive cutting tools or Jun 01, 2016 DIN 690021 Machine tools Stub spindles Part 1: General, description, basic principles Published by DIN on June 1, 2016 Diese Norm legt Maße und andere technische Daten für Kurzspindeln fest, die in ein oder mehrspindeligen Bearbeitungseinheiten als Arbeitsspindeln für die Verwendung von KS, MMS oder fürMachine tools Stub spindles GlobalSpec14 rows Machine tool spindles are rotating components used to hold and drive cutting tools or DEPRAG, Inc Machine Tool Spindles Data Sheets

Metric Machine Tool Spindles Engineering360 GlobalSpec

RWAHSK System These tools are variants of the Biax RWA line The HSK 100 or HSK 63 tool fitting allows the use of RWA spindles in machine tools Tools are available with or without regulating valve for individual adjustment of the contact pressure Design Units: Metric; Power: 0 Operating Speed: 40000A multiple spindle screw machine is an automatic bar machine that contains more than one spindle, usually four, six, or eight Multiple spindles allow multiple tools to cut multiple workpieces simultaneously A right angle drill chuck is an adapter for hand drills, which attaches to a drill chuck and drives another chuck at 90 degrees A right Machining Heads and Multiple Spindle Heads GlobalSpecMachine tool spindles are rotating components used to hold and drive cutting tools or workpieces on lathes, milling machines and other machine tools Machine Tool Spindles: Learn more Page: 1 2Machine Tool Spindles Data Sheets from HSD SpA

Machine tools Stub spindles GlobalSpec

Jun 01, 2016 DIN 690021 Machine tools Stub spindles Part 1: General, description, basic principles Published by DIN on June 1, 2016 Diese Norm legt Maße und andere technische Daten für Kurzspindeln fest, die in ein oder mehrspindeligen Bearbeitungseinheiten als Arbeitsspindeln für die Verwendung von KS, MMS oder fürABTech, Inc Datasheets for Machine Tool Spindles Machine tool spindles are rotating components used to hold and drive cutting tools or workpieces on lathes, milling machines and other machine tools Machine Tool Spindles: Learn moreABTech, Inc Machine Tool Spindles Data Sheets Robot System with Deflection and HSK Tool Fitting RWA 230HSK Robot System with Deflection and HSK Tool Fitting RWA 240HSK Robot System with Deflection and HSK Tool Fitting RWA 512HSK: RWAHSK System These tools are variants of the Biax RWA line The HSK 100 or HSK 63 tool fitting allows the use of RWA spindles in machine toolsDapra Corporation Machine Tool Spindles Data Sheets

Machine tools GlobalSpec

Aug 01, 2016 scope: This part of ISO 3070 specifies, with reference to ISO 2301, ISO 2307 and ISO 2302, geometric tests, spindle tests and tests for checking the accuracy and repeatability of positioning by numerical control of horizontal spindle boring and milling machines having a movable column along the Xaxis and also specifies the applicable tolerances corresponding to generalpurpose, normal Sep 30, 2015 Section 3 contains information for standardization of retention knobs for use with the 7/24 connection system described herein (see Table 2) Section 4 specifies the dimensions and tolerances of spindle sockets, drive keys, and key seats for machine tool spindles having 7/24 tapers intended for automatic tool change (see Table 3 and Fig 1)ASME B550 7/24 Taper Tool to Spindle GlobalSpecJun 11, 2019 Applications such as machine tool spindles, electric motors and automotive differentials require precision rotary motion with a higher degree of stiffness and positional accuracy To achieve this, a sustained load must be applied to the bearings during assembly to remove excess play This is referred to as preloading the bearingBearing preload: What is it and why is it GlobalSpec

DIN 6900113 Machine tools; Multispindle heads

Find the most uptodate version of DIN 6900113 at Engineering360Find the most uptodate version of DIN 55026 at Engineering360DIN 55026 Machine Tools; Spindle Noses with Centering Jan 03, 2020 Multispindle screwdriving machine January 03, 2020 information technology and telecommunications Video Edition Industrial MRO Industrial Processing Equipment Lab Equipment Light Laser Machine Tools Metal Working Manufacturing Technology Manufacturing Technology Video Edition Material Handling Supply Chain Technology Materials Multispindle screwdriving machine Engineering360

Machine tool cybersecurity: Preventing IIoT GlobalSpec

Apr 19, 2019 Install a robust firewall, implement more sophisticated user authentication tools and apply operating system and software updates as appropriate Data theft Hackers can steal code from a machine tool They can also use their illegitimate access to access all manner of corporate information: financials, product design, planning and personnel Jun 01, 2016 DIN 690021 Machine tools Stub spindles Part 1: General, description, basic principles Published by DIN on June 1, 2016 Diese Norm legt Maße und andere technische Daten für Kurzspindeln fest, die in ein oder mehrspindeligen Bearbeitungseinheiten als Arbeitsspindeln für die Verwendung von KS, MMS oder fürMachine tools Stub spindles GlobalSpecSep 30, 2015 Section 3 contains information for standardization of retention knobs for use with the 7/24 connection system described herein (see Table 2) Section 4 specifies the dimensions and tolerances of spindle sockets, drive keys, and key seats for machine tool spindles having 7/24 tapers intended for automatic tool change (see Table 3 and Fig 1)ASME B550 7/24 Taper Tool to Spindle GlobalSpec

Machine tools GlobalSpec

ISO 30702 Machine tools Test conditions for testing the accuracy of boring and milling machines with horizontal spindle Part 2: Machines with movable column along the Xaxis (floor type) Published by ISO on August 1, 2016Find the most uptodate version of BS ISO 7021 at Engineering360BS ISO 7021 Machine tools standardsglobalspecJul 14, 2015 Typical applications for hydrostatic and hydrodynamic bearings are machine tool spindles and slides; applications that require precise movement and high stiffness To contact the author of this article, engineering360editors@globalspec Powered by CR4, the Engineering Community Discussion – 0 commentsSpecifying Hydrostatic and Hydrodynamic GlobalSpec

Vibrationdamping technology for machining GlobalSpec

Apr 27, 2020 Accuretec promises longer tool life, productivity and process reliability and protects tools and machine spindles — despite higher cutting data Walter offers Accuretec AC001 (milling) and A3000 (turning) with all popular machine interfaces: Walter Jun 11, 2019 Applications such as machine tool spindles, electric motors and automotive differentials require precision rotary motion with a higher degree of stiffness and positional accuracy To achieve this, a sustained load must be applied to the bearings during assembly to remove excess play This is referred to as preloading the bearingBearing preload: What is it and why is it GlobalSpecMar 23, 2011 We've been monitoring spindle loading and comparing that with inline probing of machined parts to monitor tool wear and surface finish, and reset machining parameters on controllers for years I worked with this stuff in an automaker's automated engine block machining process (over 50 integrated machining centers) almost 20 years agoBlog Entry: Machine Tools Get Smart cr4globalspec

Murata Machinery USA to Demo New Muratec GlobalSpec

Aug 20, 2018 The MT200 opposedspindletype machine accommodates larger parts with a turn diameter ranging to 83 in and an 8 in chuck Visit Booth during September 1015 to learn more To contact the author of this article, engineering360editors@globalspec Milling Machine Spindle [Complete DIY Guide] [ Milling Machine Parts Home] The spindle is the heart of any mill It consists of a rotating assembly with a taper where tool holders may be installed A spindle motor with optional transmission of some kind rotates the C Milling Machine Spindle [Complete DIY Guide Oct 06, 2007 Dear friends, I am facing a problem with star type coupling plastic cushion get deformed and create play in spindle orientation This coupling is used in our machine in between spindleProblem With Star Type Coupling In Machine Spindle

Vibration monitoring of machinery using MEMS sensors

Industry 40 relies on the adoption of digital technologies to gather data in real time and to analyse it, providing useful information to the manufacturing system In this paper, what solutions modern production plants that are aspiring towards compliance with philosophy of the Industry 40 have to adopt, monitor and analyse the vibration data of the manufacturing systems using existing Jan 26, 2017 Machining systems (ie, machine tools, cutting processes and their interaction) cannot produce accurate parts if performance degradation due to wear in their subsystems (eg, feeddrive systems and spindle units) is not identified, monitored and controlled Appropriate maintenance actions delay the possible deterioration and minimize/avoids the machining system stoppage time that leads Condition based maintenance of machine tools: Vibration Find Hydrostatic Spindles related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Hydrostatic Spindles information Rotational speed 03000 rpm Pump pressure 50 bar Oil type VG 4 Oil flow 76 l/min Max axial/radial grinding force 2000/4000 N Stiffness on grinding wheel 400 N/m Friction power atgrinding spindles hydrostatic