Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

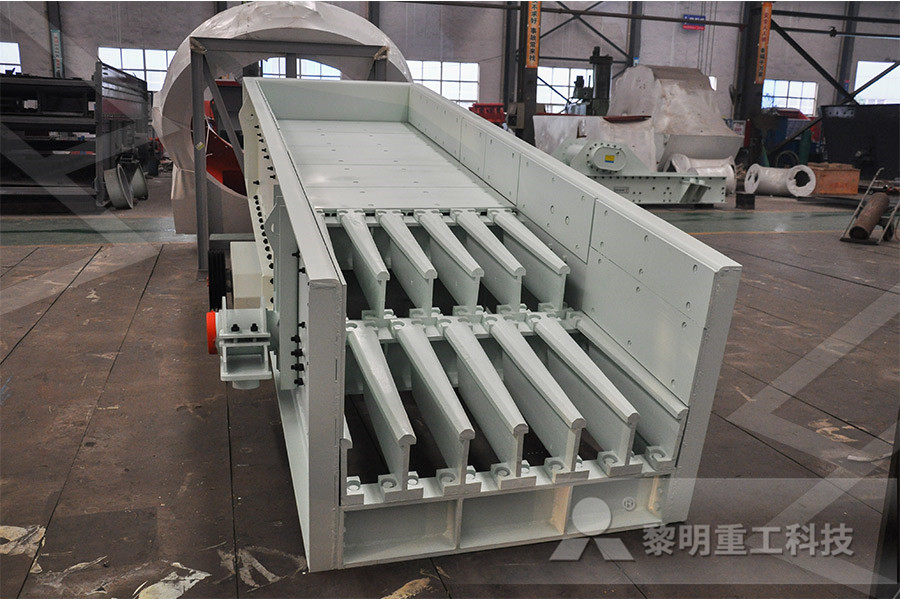

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Closed Side Setting (CSS) Measurement Device

the crusher of loose rocks 2 Conduct JSA/Take 5 equivalent on task or generate SOP (05 hour) 3 Shut down crusher Clean loose rocks, isolate crusher, feeders and conveyor belts (2 hours) 4 Obtain access to bottom of crusher, inch crusher motor manually to ensure its at the closed position then measure gap with a tape measure or equivalent Closed side setting (CSS) The closed side setting can be calculated by deducting the stroke from the OSS CSS is the most important crusher parameter since it defines the maximum product size and has significant bearing on capacity, product Crusher Close Side Settings 911 MetallurgistThe widest distance is known as the open side setting (OSS) and the narrowest, the closed side setting (CSS) These settings are important The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing productCone crusher basics in 4 minutes — SRP Sandvik

Crusher CSS Closed Side Setting Measurement VS P80

Crusher CSS Closed Side Setting Measurement VS P80 Product Size (8 replies) (unknown) 6 years ago (unknown) 6 years ago fines will consume power without significant particle size reduction if you are using cone or short heads have them choke fed for optimum performance I would recommend a design that allows the restart of equipment under Cedarapids Cone Crusher Primer 8 Bowl Float Minimum closed side setting for any cone crusher is that setting just before the Tramp Iron Relief system allows the upper section to rise against the factory recommended pressure in the hydraulic relief system This condition is defined as “Bowl Float” and indicates that the chamber crushing forces Cedarapids Cone Crusher CONE CRUSHER PRIMER The closed side setting (CSS) defines the reduction ratio in cone crushers and has a significant effect on product gradation, capacity, and power draw The closed side setting is measured from the bottom of the mantle to the bottom of the bowl liner at their closest point during the gyrating cycle CSS should be close to the required productSelecting crushing chambers for cone crusher

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Flop gate to divert material directly to cone or to second cross conveyor; Sandvik CH430 Cone Crusher ASRi ll computer automated cone control; 200 hp TEFC motor @ 1800 RPM, sheaves, vbelts; Floating subframe motor mount for cone c/w 4 rubber compression mounts; Clampon cone feed hopper c/w Overflow chute to return conveyor; Guard for cone Closed Circuit Crushing Plant ELRUS Cone Crusher A cone crusher has two sides: an open side and a closed side As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the concave As the mantle gyrates, it creates a narrow point and a wide point The distance on the wide side is known as the OSS or open side A Detailed Overview of Cone Crushers and What You

Sandvik CH660 Cone Crusher For PebbleCrushing

CH660 Cone crusher On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group We are called Sandvik Rock Processing Solutions and you’ll find all our products within Stationary Flop gate to divert material directly to cone or to second cross conveyor; Sandvik CH430 Cone Crusher ASRi ll computer automated cone control; 200 hp TEFC motor @ 1800 RPM, sheaves, vbelts; Floating subframe motor mount for cone c/w 4 rubber compression mounts; Clampon cone feed hopper c/w Overflow chute to return conveyor; Guard for cone Closed Circuit Crushing Plant ELRUS Cone Crusher TitanTM Cone Crusher Capacities Crusher Model CSS Crushing Capacities Crushing Capacities Total throughput at discharge setting (CSS) Minimum Closed Side Setting (CSS) Feed Opening at Minimum Closed Side Setting Open Closed No 2 12 mm 47” 84 mm 33” 46 mm 18 CONE CRUSHERS Telsmith

cone crushers Telsmith

crushing needs, and to recommend the cone crusher solution guaranteed to meet your production goals The Telsmith Difference is a commitment to innovative technology and service support unparalleled in the industry It is a singleminded dedication to our Closed Side Setting (A) "" The closed side setting (CSS) of our Trio® TP cone crusher can be easily adjusted using the threaded bowl and hydraulic gear drive Operating controls consist of a fully integrated hydraulic console with push button controls for clamping, clearing and adjustmentTrio® TP Series Cone Crushers Weir GroupThe cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour The adjustable crushing chamber can provide the required size of material, and is able to meet a variety of customer needs Our automation system maintains closed side settings in a Cone Crushers MEKA Crushing Screening Plants

Cone Crushers HP Series Cone Crushers Pilot Crushtec

By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product The HP cone crusher creates a higher value product with less waste Mobile : The NW300HP is a highly mobile, closedcircuit crushing and screening plant closedside sets and the gape are identified in Figure 51 The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS Throw = OSSCSS The capacity is a function of size and OSS Manufacturers publish tables of capacity for their crushers of various size as a function of the openside set 511 Cone crushersTECHNICAL NOTES 5 CRUSHERS Mineral Tech– The CH660 cone crusher is ideal for secondary and tertiary crushing, yet is compact, and possesses an easy to service design that is ideal for use as a fully tracked crushing system – The CH660 cone possesses a hydraulically adjusted Closed Side Setting and has a choice of several different crushing chambers and many other highUH640 CONE CRUSHER PIONEERING SOLUTIONS FOR YOU

MCC Series Cone Crusher Minyu Machinery Corp

The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave In general, a cone crusher runs on Vbelts driven by an electric motor or diesel engine Extensive application of Cone crusher in aggregate and mineral processing industries In order to gain a consistent aggregate quality, quantity and uniformity and achieve a balanced circuit, employees should operate cone crusher at a consistent closed side discharge setting It will result in less production and more oversized aggregate, if the crusher is operated at a widerthanoptimum setting, even if done only temporarily12 tips to maximize cone crusher productivity match the jaw crusher in the primary stage With up to 50% higher capacity, 25% increased reduction ratio and a reduced recirculation by up to 50%, with the same amount of highvalue end product compared to similar crushers in its class, the CS550 is a true super producer The wide range when it comes to Closed SideSANDVIK CS550 CONE CRUSHER

cone crushers Telsmith

crushing needs, and to recommend the cone crusher solution guaranteed to meet your production goals The Telsmith Difference is a commitment to innovative technology and service support unparalleled in the industry It is a singleminded dedication to our Closed Side Setting (A) "" closedside sets and the gape are identified in Figure 51 The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS Throw = OSSCSS The capacity is a function of size and OSS Manufacturers publish tables of capacity for their crushers of various size as a function of the openside set 511 Cone crushersTECHNICAL NOTES 5 CRUSHERS Mineral Tech TitanTM Cone Crusher Capacities Crusher Model CSS Crushing Capacities Crushing Capacities Total throughput at discharge setting (CSS) Minimum Closed Side Setting (CSS) Feed Opening at Minimum Closed Side Setting Open Closed No 2 12 mm 47” 84 mm 33” 46 mm 18 CONE CRUSHERS Telsmith

UH640 CONE CRUSHER PIONEERING SOLUTIONS FOR YOU

– The CH660 cone crusher is ideal for secondary and tertiary crushing, yet is compact, and possesses an easy to service design that is ideal for use as a fully tracked crushing system – The CH660 cone possesses a hydraulically adjusted Closed Side Setting and has a choice of several different crushing chambers and many other high The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave In general, a cone crusher runs on Vbelts driven by an electric motor or diesel engine Extensive application of Cone crusher in aggregate and mineral processing industriesHN Series Cone Crusher Minyu Machinery Corp push button control of the crusher, track and feeder functions DYNAMIC CLOSED SIDE SETTING (CSS) Dynamic adjustclosed side setting (CSS) can be changed while operating, minimizing downtime CRUSHING CHAMBER Built to be reliable in the toughest operating conditions, producing material ranging from 3/8” to 2” FEEDER Heavy Duty Hardox CONTROL PANEL C44 DYNAMIC CLOSED SIDE SETTING

New C44 Cone Crusher McCloskey International Limited

Dynamic adjustable closed side setting Dynamic adjustclosed side setting (CSS) can be changed while crushing, thus saving on downtime Telsmith Cone Built to be reliable in the toughest conditions Heavy duty hardox steel hopper combined with a metal detector automatic release system to protect the cone > Open the catalog to page 3Sandvik CS840i is a high capacity cone crusher for secondary stage crushing With up to 50% higher capacity, 25% increased reduction ratio and a reduced recirculation by up to 50%, with the same amount of highvalue end product compared to similar crushers in its class, it is a true super producer The wide range when it comes to Closed Side Settings, (CSS), together with more and bigger CS840i Cone crusher — SRPparameters such as closed side setting, stroke and eccentric speed, is accounted for On all fact, the detailed knowledge of how a cone crusher works from a process point of view is quiteCONE ResearchGate