Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

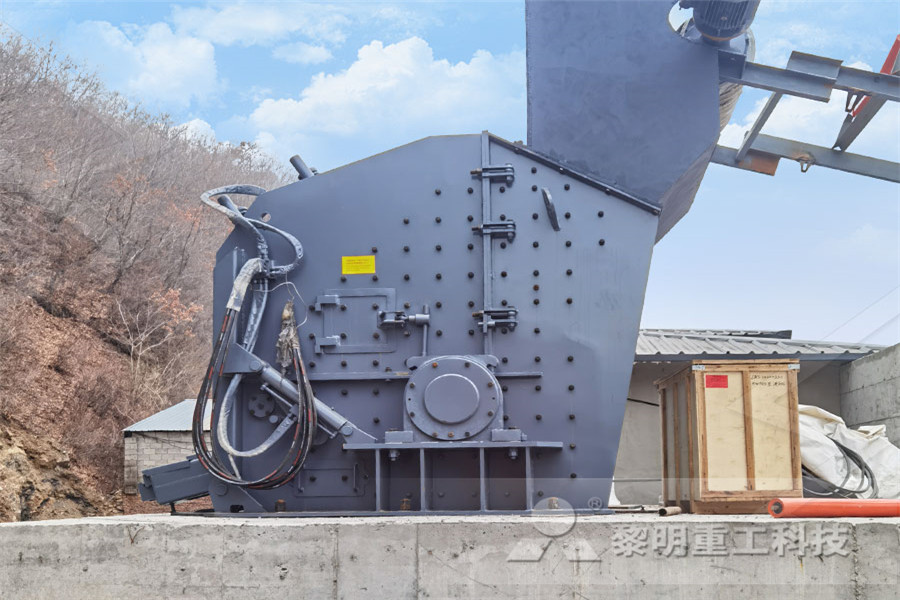

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What are the differences between ball mill and rod

Recommendation of ball mill and rod mill Ball mill and rod mill are suitable for different materials 1 Selection by material's hardness Ball mill has a strong adaptation of material, and it is suitable for grinding hard materials, such as slag, iron ore, copper ore, etc Rod mill is suitable for grinding brittle material, such as rare metals 2 The average particle is subjected to an action similar to many sets of rolls in series, before it is discharged Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit The voids (or interstitial space) within a rod load are approximately half those in a ball mill Ball Mills vs Rod Mills 911 MetallurgistThe Difference Between the Ball Mill and Rod Mill Essay 2/4/2012 Rod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16 Rod mills accept feed up to difference between rod mill and ball mill

what is the difference between the ball mill and rod mill

The difference between a rod mill and a ball mill cement The difference between ball mill and rod mill shape and structure the ratio of tube length to diameter of the rod mill is generally , and the inner surface of the lining plate on the end cover is vertical plane the ratio of cylinder length to diameter of ball mill is small, and in most cases the ratio is only slightly greater than The difference between rod mill and ball mill is that the former is loaded steel rods inside but the latter is steel balls Rod grinder crushes stones with the help of pressure and impact of steel rods When the steel rods hit against the ore, they crush from the big particles to smaller ones It is linear contact between China FTM® Grinding Rod Mill Machine for Sale Rod mills operate at lower speed than ball mills since the rods are rolled and not cascaded For an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore The rod charge must be maintained in good working condition, and broken and worn rods must be removed Rod Rod mills, how they function Mine

Rod Mill an overview ScienceDirect Topics

JeanPaul Duroudier, in Size Reduction of Divided Solids, 2016 374 Performance Rod mills are used in an open circuit between crushing and the ball mill They often operate in wet and where the pulp contains up to 50% solid by mass This machine is equally very applicable to dry where it could take a feed that has achieved 6% moisture The rod mill work index is also normally distributed The database average and median are both 148 kWh/t, which is essentially the same as the ball mill average, showing that ‘on average’ the two indices are identical However, it is common to observe a difference between the rod mill and ball mill values for a given ore type These An Overview Of the SmAllScAle teStS AvAilAble tO mill As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill indices This is because it is common to observe a difference (sometimes significant) between the rod mill and ball mill index values for a given ore type (McKen, Verret, Williams, 2006) OnSAG Mill Testing Test Procedures to Characterize Ore

Stirred Ball Mill Ore Grinding Thai Physio

Stirred Ball Mill Ore Grinding Figure 101 shows the difference in energy efficiency between a laboratory ball mill and a stirred mill grinding a gold ore using 6 mm diameter alumina balls as media at a fine grind size there is a clear advantage in energy consumption for a stirred mill over the tumbling mill however as the grind size coarsens the difference in specific energy required to Difference Between Sag Mill vs Ball Millmech4study Oct 12 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting This commutation is an copper processing machine with ball mill and mill In climb milling the cutter has the tendency to push workpiece towards the table so it is also called down milling Tendency of holding down the workpiece reduces the cutting vibration It has tendency to drag workpiece into cutter so there is a safety issue Advantages and Disadvantages of Air Bell Coleman Refrigeration System Chat OnlineAdvantages And Disadvantages Of Down Milling

ball mill process lead oxide quarry crusher

Lead Oxide Powder Density Ball Mill Pdf czeueu lead oxide powder density ball mill pdf YouTube ball mill process for lead oxide,9 Dec 2013, Posts Related to lead oxide powder density ball mill pdf red oxide primer manufacturing process project report Projects on Paints, Pigments, Enamels,, lead oxide density ball mill pdf Grinding Mill China lead oxide denclean lead Feb 26, 2018 Mineral Jig Machine jig separator is an effective mineral gravity separator, can separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin Inquire Now; Gravity Separation PlantGravity Separator Gravity separation works on basic of density difference between useful minerals and other gangues in moving waterflowsgravity wet small gold separate plant 」Material Consumption Patterns in India A Baseline Study of the Automotive and Construction Sectors(PDF) Material Consumption Patterns in India A

Roller Mill For Crushing Limestone Stone Quarry

Roller Mill For Crushing Limestone Stone Quarry Conveyor Roller Crusher For Mining, Roller Crusher For Mining Alibaba offers 9,067 roller crusher for mining products About 74 of these are crusher, 1 are plastic crushing machines, and 1 are other food processing machinery A wide variety of roller crusher for mining options are available to you, such as roller crusher, cone crusher, and hammer