Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

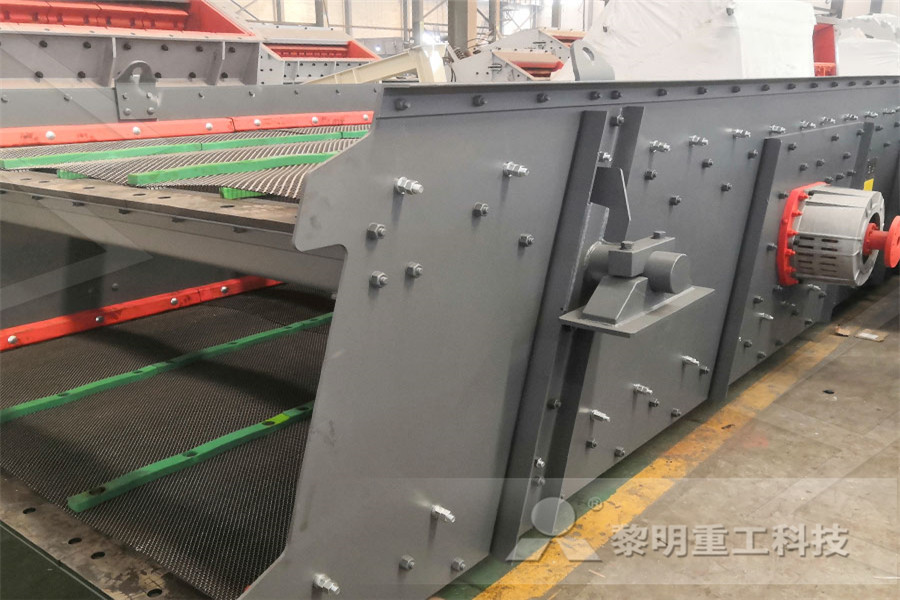

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed May 06, 2021 In one respect, the working principle and application of this machine is similar to all type of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointJaw Crusher Working Principle 911 MetallurgistWhile being applied for different purpose, jaw crushers are designed with various structures Are you interested in the working principle of jaw crusher? The working principle of jaw crusher is very simple The whole crushing process rely on the relative motion of the two jaw plates One of the jaw plates stay still while the other move against itWhat Is the Use and Working Principle of Jaw Crusher?

Construction And Working Principle Of Jaw Crusher

Jaw Crusher Working Principle Jaw Crusher Supplier jaw crusher is much more than the tiger’s mouthIt is composed of dynamic and static jaw of crusher Jaw Crusher Working Principle construction Dec 25, 2014 The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamberThe Working Principle Of A Jaw Crusher Editors TopFeb 17, 2016 Gyratory crushers work on a similar principle to jaw crushers but have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis These are generally designed for primary crushing in largescale rock crushing applications up to 6000 t/hWorking Principle of Crushers 911 Metallurgist

Jaw crusher SlideShare

Dec 09, 2014 8 • Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle • A Jaw Crusher reduces large size rocks or Working principle of jaw crusher: Through transmission of belts, the motor drives the eccentric shaft Under drive of the eccentric shaft, the moving jaw does periodic motion towards the fixed jaw When the space between the moving jaw and the fixed jaw reduces, the materials will be crushedWhat is the working principle of jaw crusher? QuoraA jaw crusher uses compressive force (mechanical pressure) for breaking of particles Above figure shows construction of a typical single toggle Blake type jaw crusher As shown in above figure, a jaw crusher consists of a set of vertical jaws The volume or cavity between the two jaws is called the crushing chamberConstruction, Working and Maintenance of Crushers for

How does a Jaw Crusher Work Mineral Processing YouTube

Mar 05, 2013 How does a Jaw Crusher Work Mineral ProcessingLIKE, SHARE SubscribeThe distinctive feature of this class of crusher isthe two plates which open and shuWhile being applied for different purpose, jaw crushers are designed with various structures Are you interested in the working principle of jaw crusher? The working principle of jaw crusher is very simple The whole crushing process rely on the relative motion of the two jaw plates One of the jaw plates stay still while the other move against itWhat Is the Use and Working Principle of Jaw Crusher?Jaw Crusher Working Principle Jaw Crusher Supplier jaw crusher is much more than the tiger’s mouthIt is composed of dynamic and static jaw of crusher Jaw Crusher Working Principle construction Construction And Working Principle Of Jaw Crusher

What is a Jaw Crusher and Selecting the Right One Gilson Co

Many of these materials are hard, tough, or brittle, so crushing them to smaller sizes is an ideal application for robust, rugged, and durable jaw crushers The Working Principles Of A Jaw Crusher All jaw crushers operate on the same straightforward principle; two hardfaced heavy plates or jaws crush large particles between themJaw Crusher Working Principle A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointjaw Impact Crusher Working Principle – High Quality and Changing the discharge opening controls the product size made by the crusher Jaw crushers are mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industriesWhat is a Jaw Crusher? Telsmith

Jaw crusher SlideShare

Dec 09, 2014 • Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the 4 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Compression Crushing by compression is done between two surfaces, with the work being done by one or both surfaces For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rockConstruction, Working and Maintenance of Crushers for Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit Types of Jaw Crushers Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

jaw crusher application of the principle of

jaw crusher principle application is one of the biggest manufacturers in Aggregate Processing Machinery for the jaw crusher principle application, sand gravel, quarry, mining, construction and building material, highway construction, railway construction and the chemical industry to process the materials 4 Working principle Shown as Figure1, the machine is mainly constituted by machine frame, movable jaw, eccentric shaft, jaw plate and adjusting bed etc When machine is working, the eccentric shaft is driven by the motor through theOPERATING INSTRUCTION ToolDepotSandvik Construction Mobile Crushers and Screens Ltd Tullyvannon, Ballygawley, CoTyrone, Northern Ireland, BT70 2HW Tel +44 (0) 28 8556 7799, Fax +44 (0) 28 8556 7007QH441OperationManual Crusher Works

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O’Mahony, 1990) Gyratory crushers work on the same principle as cone crushers (Figure 44(c)) These have a gyratory motion driven by an Gyratory Crusher an overview ScienceDirect TopicsOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect Topics

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock They crush primarily by using compression The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is While being applied for different purpose, jaw crushers are designed with various structures Are you interested in the working principle of jaw crusher? The working principle of jaw crusher is very simple The whole crushing process rely on the relative motion of the two jaw plates One of the jaw plates stay still while the other move against itWhat Is the Use and Working Principle of Jaw Crusher?Many of these materials are hard, tough, or brittle, so crushing them to smaller sizes is an ideal application for robust, rugged, and durable jaw crushers The Working Principles Of A Jaw Crusher All jaw crushers operate on the same straightforward principle; two hardfaced heavy plates or jaws crush large particles between themWhat is a Jaw Crusher and Selecting the Right One Gilson Co

Jaw crusher SlideShare

Dec 09, 2014 • Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit Types of Jaw Crushers Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types How Does a Jaw Crusher Work Jaw Crusher Kemper EquipmentFields of application and design characteristics Schematic diagram of the working principle of a singletoggle jaw crusher with a singletoggle system Left: Average throughput rate of singletoggle jaw crusher, hardrock version, tolerance ± 10% 100 150 swing jaw moves forward Serrated jaw plates enhance the crushing processIndustrial Solutions Jaw crushers ThyssenKrupp

jaw crusher working principle gondwanauniversity

Apr 01, 2008 Jaw Crusher Working Principle blog/jaw crusherIt will be noted that the motion is a rocking one When the swing jaw is rising, it is opening, at the top, during the first half of the stroke, and closing during the second half, whereas the bottom of the jaw is closing during the entire up strokeApplication fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher With Different Models Jaw Crusher: Range, Working Principle, Application Jaw crushers are used as primary crushers, or the first step in the process of reducing rock Operation Principle Of A Jaw Crusher China Operation Principle Of A Jaw Crusher 41 4 cone crusher instructions Working principle: The motor drives belt and belt wheel, when movable jaw plate principle of equipment operation of jaw crusher

principles of oparations for jaw crusher

Feb 13, 2021 Fundamental principles of rock jaw crusherundamental principles crusher supremewheelsor a planar mechanism, such as the single toggle jaw crusher, principle of operation of jaw crushers youtubeeb 14, 2016 the robust design and powerful drive of this jaw crusher make it an excellent choiceundamental principles of operation forread moreSep 02, 2019 In a jaw crusher, the major wear parts are very limited – only a fixed jaw and a swing jaw, and two or four side or cheek plates An impact crusher, on the other hand, has a lot more wear items The blow bars, which hit the rock and make it explode inside the machine, take a PQ University Lesson 7 Crushing Secondary Breaking The appearance and working principle of the 2 crushers are different The jaw crusher is of the curved dynamic extrusion type, and the materials are crushed in the crushing cavity composed of the moving jaw and the fixed jaw The hammer crusher is mainly broken by the impact, shear and tear of the rotating hammer head, the mutual impact between Hammer Crusher VS Jaw Crusher Which Is Better (7 Tips) MC

mobile jaw crusher, mini jaw crusher, portable jaw crusher

These designs make diesel engine jaw crusher favored by most of people Small Jaw Crusher Working Principle Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular op ening design Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw board, mounted isc vsi rock crusher maintenance – Crusher Machine used vsi crushers for sale,vsi crusher working principle Crusher,Rock Crusher,Jaw Crusher,Stone Crusher Machine the features of stable operation, Click Chat NowVsi Stone Crusher Principle Operation Manual