Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

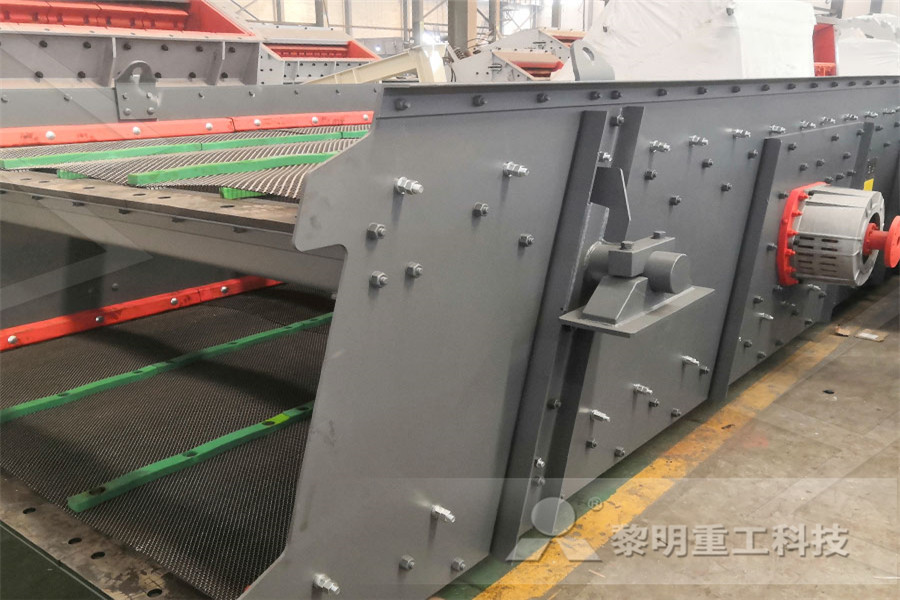

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

quarry dust in stabilised earth blocks Products

quarry dust in stabilised earth blocks 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon 250tph limestone crushing line in Kenya 250tph granite crushing line in South Africa MCC 120tph granite crushing line in Zimbabwe 400tph crushing plant in GuineaStabilized compressed earth block is an innovative advancement of the traditional earth technology and quarry dust, cow dung have been used to stabilise laterite blocks and also cohesive soils in the case of road construction The effect of these materials on black cotton soil blocks Potential of Quarry Dust and Cow Dung as stabilisers for Quarry dust was collected from a place called Thadagam 35 km from the study area The stabilized soil blocks have been caste using ITGE VOTH block making machine at Kattida Maiyam, Vadavalli, Coimbatore (Fig1) The economy and strength of the stabilized soil blocks majorly depends on the type of stabilizer chosen 4Economic Consideration of Stabilized Soil Blocks

Introduction to QuarryDust as Partial Replacement

May 19, 2020 QUARRY DUST IN SOIL STABILIZATION AND IN BRICKS Fine and Coarse aggregate are basic need of construction industry and can be replaced by quarry dust which is a byproduct of rubble crusher units It contains some Geotechnical and mineralogical characterization which can easily interact with soilblocks as a replacement to sand, and also to make the blocks economical Quarry dust was obtained from a locally available commercial vendor Admixtures used in the preparation of blocks were Ordinary Portland cement (OPC) of 53 grade and pressed stabilized earth blocks using iron mine spoil Comparative analysis of properties of quarry dust stabilized and unstabilized compressed earth blocks DrEngManguriu EN251C00070025/10: Design of a 12 storey building on weak soils, case study Nakuru MrNjuki EN2513599/2010Projects Department of Civil, Construction and

Research Paper EXPERIMENTAL INVESTIGATION ON CEMENT

Materials such as Fly Ash and Quarry Dust are also used to reduce the usage of cement and soil contents in various proportions were examined to arrive a cost effective and sustainable bricks cement stabilized soil blocks with a view to make available the existing experiences in this field to those who produce or plan to manufacture blocks so as to improve production techniques and quality of outputinterlocking compressed stabilised earth block (CSEB) which is used alternative to traditional brick and mortar construction In conventional concrete masonry little to no clay is allowed in brick/block manufacture [1], making Aeolian, river or crushed rock sands the preferred sands for manufacturing conventional masonry unitsDURABILITY OF COMPRESSED STABILISED EARTH BLOCKScement stabilization, the blocks must be cured for four weeks after manufacturing After this, they can dry freely and be used like common bricks with a soil cement stabilized mortar Since the early days, compressed earth blocks are most of the time stabilised Therefore, we prefer today to call them Compressed Stabilised Earth Blocks (CSEB)COMPRESSED STABILISED EARTH BLOCKS

Compressed Stabilized Earth Blocks Ministry of Housing

Jul 11, 2017 compressed stabilized earth blocks (cseb) Cement stabilized earth blocks are used an alternative building material for burnt clay bricks and cement, sand blocks This is an appropriate and costeffective wall construction material as most of the generally available sandy soil and gravel soil can be used for manufacturing of these blocksStabilized compressed earth block is an innovative advancement of the traditional earth technology and quarry dust, cow dung have been used to stabilise laterite blocks and also cohesive soils in the case of road construction The effect of these materials on black cotton soil blocks Potential of Quarry Dust and Cow Dung as stabilisers for It is thus confirmed that the addition of quarry dust and cowdung have significant positive effects on black cotton soil, rendering them suitable for use sustainable ecoblocks for construction Keywords : Black cotton soil, quarry dust, cow dung, compressive strength, cracks, shrinkage, ecoblocks, compressed earth blocks, stabilized soil blocksPotential of Quarry Dust and Cow Dung as stabilisers for

Quarry Dust Interlocking Blocks

About quarry dust in stabilised earth blocksrelated information:a daily newspaper covering san francisco, san mateo county and serving alameda, marin and santa clara counties »» quarry dust interlocking blocks Read more replacement of sand by quarry dust in block abstractconsidering the economic analysis Furthermore, laboratory test shows that the quarry dust can improve the compressive strength of Compressed Stabilized Earth Blocks From test results, it was observed that the curing period of 7 days is enough to achieve the required compressive strength for GradeI category of Compressed Stabilized Earth BlocksAn Experimental and Analytical Study of the Critical blocks as a replacement to sand, and also to make the blocks economical Quarry dust was obtained from a locally available commercial vendor Admixtures used in the preparation of blocks were Ordinary Portland cement (OPC) of 53 grade and pressed stabilized earth blocks using iron mine spoil

The potential of cement stabilized shale quarry dust for

Dec 18, 2017 This research investigated the potential of cement stabilized shale quarry dust for possible use as road foundation material From the results, the shale consists mainly of SiO2 (277–601%), Al2O3 (730–179%), CaO (391–323%) and LOI (493–188%) The shale quarry dust (SQD) in its natural state had an average liquid limit (LL) as 38%, plasticity index (PI) as 24% and Compressive Strength and Costs of Sandcrete Blocks and Blocks cost implications The finding proves that blocks made with quarry dust are In most villages, mud and clay materials are still being used for wall making with their acceptability as last alternative for the poor but, with some level of quality sandcrete block sample was sourced as river sharp sand while the cement used forquarry dust as alternetive to sand in block production pdfused in the process of stabilised blocks production, the amount of cement used can be reduced by the use of materials such as Fly Ash, lime, quarry dust as well as sand which the percentage vary depending on the type of soil The main objective of this work is to compare the compressive strength of block produce using 2 layers hand compaction andEFFECT OF HAND COMPACTION ON COMPRESSIVE

Projects Department of Civil, Construction and

Comparative analysis of properties of quarry dust stabilized and unstabilized compressed earth blocks DrEngManguriu EN251C00070025/10: Design of a 12 storey building on weak soils, case study Nakuru MrNjuki EN2513599/2010Jan 16, 2019 Compressed Stabilized Earth Blocks, known as CSEB, are unfired blocks produced by mixing soil, sand, stabilizer (cement or lime), and water and compressing the mixture into block form with either a manual or a motorized press These blocks can then be used in masonry construction in buildings up to four stories tall without concrete column Compressed Stabilized Earth Block and Rammed Earth for Experimental Investigation on Cement Stabilized Soil Blocks ijscer Materials such as Fly Ash and Quarry Dust are also used to reduce the usage of cement and soil contents in various proportions were examined to arrive a cost effective The cost of production and energy audit by the soil blocks has been Read moreUse Of Quarry Dust In Block Production

Research Paper EXPERIMENTAL INVESTIGATION ON CEMENT

fabricate the stabilized soil blocks The mix proportions are calculated and the blocks have been casted and cured for 28 days Materials such as Fly Ash and Quarry Dust are also used to reduce the usage of cement and soil contents in various proportions were examined to arrive a Stabilized Compressed Earth Blocks (SCEB), are an improved version of earth based masonry units These masonry blocks are made by compressing earth/ soil by • Quarry dust = 18 kg • Cement =0252kg • Water content = 0648 l 33 Stabilized mud block of cement (5%) +conventional brick block IJSERquarry dust and 55% laterite According to figure 5and 6 both wet and dry compressive strengths of the blocks (45% of quarry dust and 100% of laterite) were increased with cement percentage But the strength of material mixture (45% of quarry dust) is higher than 100% quarry dust at both wet and dry conditions It was obtained that theANR Wickramasinghe (1) and NWB Balasooriya

Potential of Quarry Dust and Cow Dung as stabilisers for

It is thus confirmed that the addition of quarry dust and cowdung have significant positive effects on black cotton soil, rendering them suitable for use sustainable ecoblocks for construction Keywords : Black cotton soil, quarry dust, cow dung, compressive strength, cracks, shrinkage, ecoblocks, compressed earth blocks, stabilized soil blocksconsidering the economic analysis Furthermore, laboratory test shows that the quarry dust can improve the compressive strength of Compressed Stabilized Earth Blocks From test results, it was observed that the curing period of 7 days is enough to achieve the required compressive strength for GradeI category of Compressed Stabilized Earth BlocksAn Experimental and Analytical Study of the Critical Stabilized Compressed Earth Blocks (SCEB), are an improved version of earth based masonry units These masonry blocks are made by compressing earth/ soil by • Quarry dust = 18 kg • Cement =0252kg • Water content = 0648 l 33 Stabilized mud block of cement (5%) +conventional brick block IJSER

EFFECT OF HAND COMPACTION ON COMPRESSIVE

used in the process of stabilised blocks production, the amount of cement used can be reduced by the use of materials such as Fly Ash, lime, quarry dust as well as sand which the percentage vary depending on the type of soil The main objective of this work is to compare the compressive strength of block produce using 2 layers hand compaction andquarry dust and 55% laterite According to figure 5and 6 both wet and dry compressive strengths of the blocks (45% of quarry dust and 100% of laterite) were increased with cement percentage But the strength of material mixture (45% of quarry dust) is higher than 100% quarry dust at both wet and dry conditions It was obtained that theANR Wickramasinghe (1) and NWB Balasooriya Stone dust is a fine material that absorbs moisture readily, then releases it slowly The same properties that work wonders for organic gardening can wreak havoc underneath pavers, causing efflorescence and allowing them to settle or shift easily under load In extreme frostthaw cycles, watersoaked stone dust can actually pump up through the Stone Dust Doesn't Belong Under Pavers Here’s Why

Stabilised Soil an overview ScienceDirect Topics

BV Venkatarama Reddy, in Modern Earth Buildings, 2012 Abstract: Stabilised soil blocks (SSBs) are energy efficient and low embodied carbon alternative materials for structural masonry there is an upsurge of interest among building professionals in utilising low embodied carbon materials This chapter deals with various aspects of SSBs applicable to structural masonryearth block when wet or damp soil is pressed at a high pressure to form the block whereas it is called a compressed stabilized earth block wherein any binder is used for the stabilization of the soil used in the manufacture of the block A lot of materials have been used for stabilization of soil including cement, lime, yash, gypsum, and Research Article Cement Stabilized Soil Blocks Admixed Aug 07, 2020 Where to Buy Stone Dust (Including How Much to Buy) You can buy stone dust at most stone yards and quarries Some excavation companies also sell it, along with the crushed stone, sand, gravel, bricks, flagstones, etc that you might need for other projects For a fee, most of these places will deliver the product to your propertyWhere to Buy Stone Dust And What It Is, How to Use It

Understanding stabilised mud blocks The Hindu

Jan 23, 2015 Alternatively, other construction techniques like rammed earth and stabilised adobe can be used without the need of a mud block press Utilisation of For example, the Auram press 3000 proposes 18 types of moulds for producing about 70 different blocks Compressed earth blocks can be stabilised or not But most of the times, they are stabilised with cement or lime Therefore, we prefer today to call them Compressed Stabilised Earth Blocks Compressed Stabilised Earth Block Auroville Earth InstitutePage 4 MATERIALS Materials required for construction of Compressed Stabilised Earth Blocks (CSEB) are as follows: Cement: The cement shall confirm to either IS 269 or IS 1489 (Part1) or IS 8112 or IS 12269 Lime: Lime shall confirm to IS 712 Sand: The sand to be used for diluting the soils shall be either natural river sand, crushed stone sand or crushed gravel sand confirming IS 383DETAILED PROJECT REPORT CSEB WordPress

URBAN ENERGY TECHNICAL NOTE PROMOTING ENERGY

Interlocking Stabilised Soil Blocks (ISSB) (such as sand or quarry dust) and a higher cement content to prevent the blocks from cracking 2 Stabiliser UNHabitat (2009) Interlocking Stabilised Soil Blocks: Appropriate Earth Technologies in Uganda Nairobi, Kenya: UNHabitat UNHabitat Quarry Dust Block Making Specification Henan Mining masonry Water Absorption Good quality blocks can be made from Hydraform machine to give For Fly Ash Cement Up to 15 For Stabilized Earth Block Up to 12 Block Finish Block finish is very good and compares even better than face brick finishRatio Of Quarry Dust And Cement In Making Bricks Machine