Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

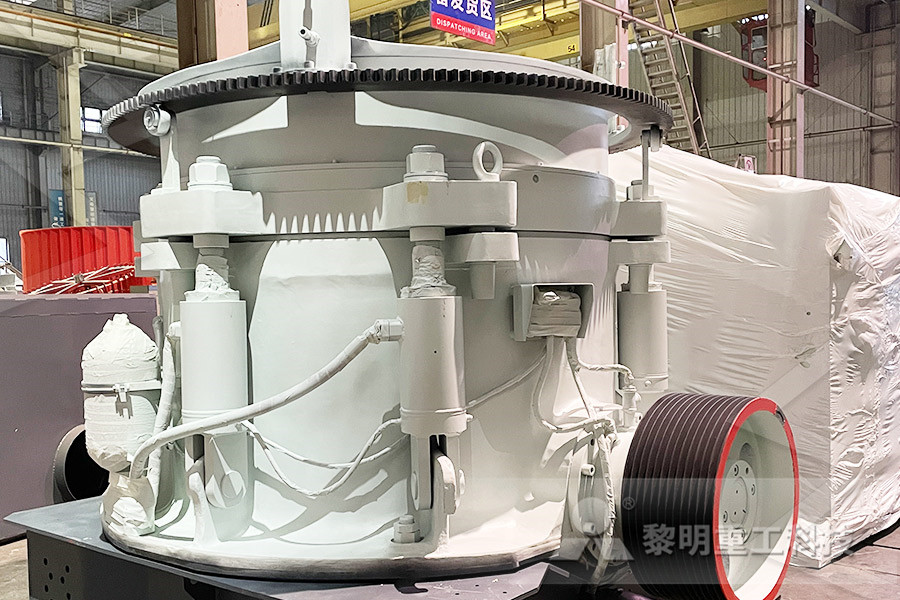

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Laboratory Grinding Mill 911 Metallurgist

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or cyanidation Practice varies, depending upon the type of ore and the amount of reduction requiredJul 15, 2020 SAG mill – Large pieces of ore coming for grinding with a small addition (810% of the mill volume) of steel balls with a diameter of 100150 mm; In some cases, steel or castiron cymbals are used as a grinding medium, representing bodies in the form Ore Grinding MillsTypes and Classification – Mineral Aug 17, 2018 Grinding Mills — Types, Working Principle Applications to get a crushed product that can be directly used for industrial application or to recover a metal from a complex oreGrinding Mills — Types, Working Principle Applications

Grinding Mills and Their Types – IspatGuru

Apr 09, 2015 The grinding mills are categorized in three groups, namely (i) tumbling mills, (ii) roller mills, and (iii) very fine grinding mills which include (a) high speed pulverizing or hammer mill, (b) vibrating mill, (c) pin mill, (d) turbo mill, (e) fluid energy mill, (f) stirred media mill Terms used in grinding of materialsDec 22, 2011 Many different types of mill has been developed for special applications Some mills can grind various materials but some others are only used for certain requirements There are different factors as following should be considered before choosing a grinding mill Mineral properties This is the primary factor should be considered to choose a mill,How to choose a right grinding mill Stone Crusher used May 10, 2019 The medium filling rate is the volume ratio of the medium and grinding cavity, moves in throwing and falling state in a ball mill The throwing motion medium is used to smash large ore, and the medium of falling movement mainly plays the role of grinding The filling rate of the fine grinding mill is about 5% lower than that of the coarse grindingFactors Influence Ore Grinding Mill Efficiency JXSC Mining

Fine Grinding as Enabling Technology – The IsaMill

Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment the ability to use fine grained media (eg 1 mm) to suit to the fine grained feed the ability to use cheap natural products (local sand, slag, ore) as grinding mediaApr 25, 2013 EQUIPMENT USED A HighIntensity Stirred Mills Fine grinding is usually performed in highintensity stirred mills; several manufacturers of these stirred mills exist Two frequently used stirred mills include the Isamill, produced by Xstrata Technology, and the SMD, produced by (Figure 1)Energy Use of Fine Grinding in Mineral ProcessingAug 17, 2018 Grinding Mills — Types, Working Principle Applications to get a crushed product that can be directly used for industrial application or to recover a metal from a complex oreGrinding Mills — Types, Working Principle Applications

Five Popular types of grinding mills Stone Crusher used

Feb 01, 2012 grinding process In most industries, size reduction could be divided into main categories: crushing and grinding Grinding, also called fine milling or pulverising, is the process of reducing materials to fine powder or very fine particle size Grinding process is different from crushing, which reduce the big massive materials to a rock, pebble or grain sizeore grades decreasing and becoming more complex to process and energy costs rising, new ways to costeffectively liberate minerals and maximize recovery levels are required The Outotec HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational OUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY Dec 22, 2011 Many different types of mill has been developed for special applications Some mills can grind various materials but some others are only used for certain requirements There are different factors as following should be considered before choosing a grinding mill Mineral properties This is the primary factor should be considered to choose a mill,How to choose a right grinding mill Stone Crusher used

What is Ball Mill How Many Types of Ball Mills MC

(1) Types on the Basis of Cylinder 1 Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, ie the ball mill with L ≤ 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in seriesApr 25, 2013 Millpebs have been used as grinding media to achieve fine grinding in ball mills These are 5 to 12mm spherical or oblong cast steel pellets, charged into ball mills as a replacement of, or in addition to, balls While Millpebs can give significantly lower energy use when grinding to finer sizes, they also can lead to high finesEnergy Use of Fine Grinding in Mineral ProcessingBall mill uses steel ball as grinding medium Because the steel ball is in point contact with the ore, the grinding products are of high fineness, and the particle size of the products is relatively fine, which is prone to over grinding, so ball mill is not suitable for the reselection production line in ore dressingBall Mill vs Rod Mill How To Choose Ball Mill or Rod

Mill (grinding) — Wikipedia Republished // WIKI 2

Jan 20, 2021 SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in diameter, powered by a 28 MW (38,000 HP) motorIndustrial ball mills can operate continuously, being fed at one end with the ore and discharging the fine powder at the other end Rod mills are quite similar to ball mills but use long steel rods instead of small balls for the grinding media Steel rods grind the ore by tumbling within the mill and the rods tumble and spin in roughly parallel Benefits of Used Grinding EquipmentComminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes In geology, it occurs naturally during faulting in the upper part of the Earth's crust In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with Comminution Wikipedia

Stirred mills for wet grinding Outotec

The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills energy efficient grinding machines Vertimill® energy savings can range from 30% to greater than 50% compared with traditional mills, and the SMD energy savings can be far greater than 50% of ball mill energy in fine grindsIsaMill™ Technology Used in Efficient Grinding Circuits BD Burford1 and LW Clark2 High intensity stirred milling is now an industry accepted method to efficiently grind fine and coarse particles In particular, the IsaMill™, which was invented for, and transformed the fine grindingIsaMill Technology Used in Effecient Grinding CircuitsMar 08, 2021 2 When the tungsten ore, tin ore or other rare metal ores are selected by gravity separation or magnetic separation, rod mill is often used to prevent over crushing 3 In the twostage grinding process, rod grinding machine is generally used as the first grinding equipment, which has the advantages of larger production capacity and higher What are the differences between ball mill and rod mill

Raymond Mill Milling Equipment China Largest Mining

Raymond mill is widely used in ultrafine grinding process of barite, calcite, potassium feldspar, limestone, talc, marble, dolomite and gypsum, etc It also can do the super fine grinding process of nonflammable and nonexplosive ore, chemical and construction materials with Mok's hardness under 93 and humidity below 6%Feb 01, 2012 grinding process In most industries, size reduction could be divided into main categories: crushing and grinding Grinding, also called fine milling or pulverising, is the process of reducing materials to fine powder or very fine particle size Grinding process is different from crushing, which reduce the big massive materials to a rock, pebble or grain sizeFive Popular types of grinding mills Stone Crusher used ore grades decreasing and becoming more complex to process and energy costs rising, new ways to costeffectively liberate minerals and maximize recovery levels are required The Outotec HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational OUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY

Crushing Grinding Equipment Sepor, Inc

The Attritor mills (010E500 010E510) can be operated in a batch or continuous mode, utilizing either dry grinding or wet grinding When used in continuous grinding, the material is fed into the vessel at the top It then falls through the agitating media bedJan 20, 2021 SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42' (128m) in diameter, powered by a 28 MW (38,000 HP) motorMill (grinding) — Wikipedia Republished // WIKI 2As lower ore grades and complex mineralogy are driving demand for more efficient fine grinding, you can depend on for a full range of finegrinding mills designed for easy shipment, simple erection and troublefree maintenanceStirred mills for milling grinding

Crushing Grinding – The Anchor House, Inc

Sep 09, 2016 The grinding media for a ball mill is usually steel balls sized from about 1 to 10 cm in diameter, and for rod mills about 1 to 10 cm in diameter, with the length being slightly shorter than the length of the rod mill The grinding circuit product can be made very fine, if necessary, with the majority of material finer than 20 microns (um)Industrial ball mills can operate continuously, being fed at one end with the ore and discharging the fine powder at the other end Rod mills are quite similar to ball mills but use long steel rods instead of small balls for the grinding media Steel rods grind the ore by tumbling within the mill and the rods tumble and spin in roughly parallel Benefits of Used Grinding EquipmentJul 01, 2015 Tumbling mills for size reduction with either steel rods (rod mills) or balls (ball mills), or sized ore (AG SAG mills) as the grinding media used depending upon COMMINUTION: Liberation, Crushing, Grinding

Comminution Wikipedia

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes In geology, it occurs naturally during faulting in the upper part of the Earth's crust In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with Tumbling mills For coarse particle grinding in tumbling mills equation 1 is written as: f x f x 2 1 a 1 ia 4 2 W K M x x 1 (4) where K 1 = 10 for all circuits that do not contain a recycle pebble crusher and 095 where circuits do have a pebble crusher x 1 = P 80 in microns of the product of the last stage of crushing before USING THE SMC TEST® TO PREDICT COMMINUTION Apr 26, 2019 They are usually applied in the grinding process of copper, gold, iron ore and polymetallic Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic ball mills Ball Mill Grinding Media Options Orbis Machinery, LLC

Swiss Tower Mills Minerals AG

The unique grinding technology, which Swiss Tower Mills Minerals AG offers for the mineral processing industries, has been well proven over more than 40 years in the industrial mineral segment: over 200 fine and ultrafine grinding mills are in operation, with a total installed power of over 300 MWThe VXPmills are designed for fine and ultra fine grinding applications In practice, the mill performs best when the feed has a normal distribution However, the mill has been used to preferentially grind the coarser “hump” in bimodal distributions without over grinding the finer part of the distributionVXPmill for fine ultra fine grinding Applied to ore milling applications, our hammer mills can produce flourfine rock powder Glass pulverizing, rock recycling, porcelain recycling, and similar material reduction projects achieve slightly variable output sizes, from powder to ricegrain sized discharge, per operator specifications using slotted screens or punch plate holes as Hammer Mills Mt Baker Mining and Metals