Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

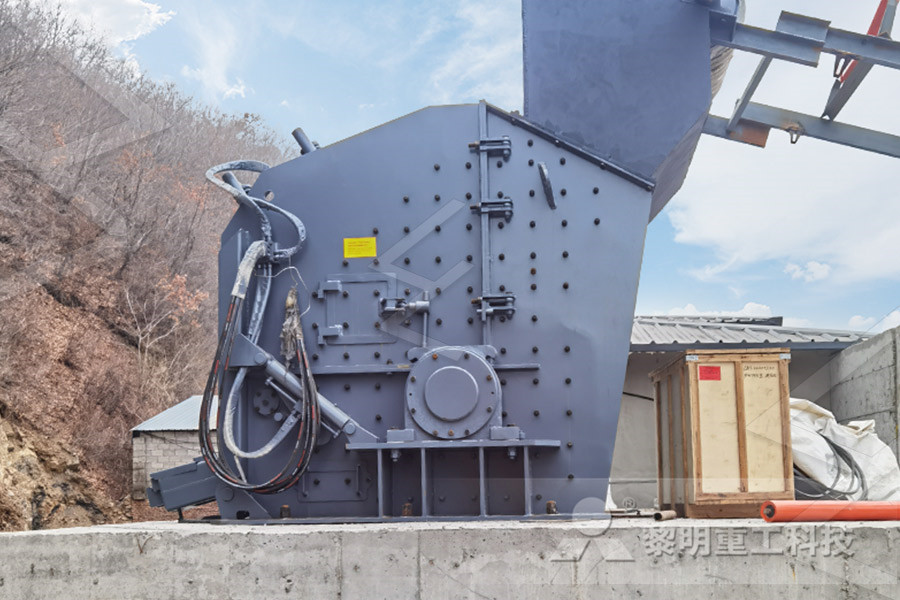

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Aggregate Crushing PlantHigh Safety High Efficiency

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power systemAggregates between 12mm and 32mmwill be conveyed to one place as coarse aggregate or 02 Then those passing and retained by 5mm sieve will be taken two different places as fine aggregates (00 and 01) StorageThe end materials are then taken by loaders and stocked on appropriate places until selling Normally fine aggregates are moved directly(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw Nov 22, 2020 An aggregate crushing plant processes nonmetallic minerals to make them suitable for the construction industry The aggregate crushing plant first segregates the aggregates according to their type and size It will then reduce the aggregates by crushing them downHow Aggregate Crushing Plant and Processing Works

Aggregate Processing and Aggregate Crushing Plant

Jul 20, 2019 Aggregate crushing plants are important equipment for aggregate processing Aggregate commonly is classified into two categories: fine aggregate and coarse aggregate Fine aggregate is the materials that could pass the No4 sieve, and most could be retained on a The coarse crushing equipment used for the production of aggregates is generally a rotary crusher, jaw crusher and impact crusherAggregate Crushing Plant and Processing Sand Maker Apr 20, 2019 The particle size above 5mm is called coarse aggregate, which is often called stone Camelway has years of experience in producing sand and gravel aggregate equipment At the same time, our crushing plants provides high quality sand and gravel aggregates for many projectsSand and Gravel Aggregate Process Plant, Construction

5 Aggregate Production in

After primary crushing/reduction the resulting aggregate generally is placed in a large "surge" pile where the aggregate may be fed into the secondary operation whenever convenient Care is always taken when building up and loading out surge piles, as this step may be a major source of segregation of material going to the secondary plantThe fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies with today’s tough environmental regulations, and can be built at a reasonable price despite the rising costs of equipment, energy and construction laborCrushing Plant Design and Layout Considerationscrusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and the grizzly throughs (undersize material) are discharged onto a belt conveyor and usually are conveyed to a surge pile for temporary storage or are sold as coarse aggregates The stone from the surge pile is conveyed to a vibrating inclined screen called theAP42 Section 11192 Crushed Stone Processing and

What is Crushed Aggregate? (with pictures)

Coarse crushed aggregate is commonly used in landscaping designs All aggregate is divided into two types: fine and coarse Fine aggregate is broken up into smaller pieces than coarse aggregateNov 22, 2020 Fine aggregate find their way into the concrete mix while coarse professionals use coarse aggregate on the roads and pathways Aggregate crushing plant An aggregate crushing plant processes nonmetallic minerals to make them suitable for the construction industry The aggregate crushing plant first segregates the aggregates How Aggregate Crushing Plant and Processing WorksCoarse aggregate is often used to make the skeleton of the building and the fine aggregate is more used for fill Accordingly, the processing equipment for the coarse and fine aggregate is different aggregates making plant is mainly a variety of aggregates production line, such as: coarse aggregate crushing production line and fine Aggregates making plant for coarse and fine aggregate

Sand and Gravel Aggregate Process Plant, Construction

The particle size above 5mm is called coarse aggregate, which is often called stone Camelway has years of experience in producing sand and gravel aggregate equipment At the same time, our crushing plants provides high quality sand and gravel aggregates for many projects Aggregate Crushing Plant Aggregate production line produce construction aggregates widely used for making concrete production The aggregate process consists by progressive stages of crushing, screening, and washing Aggregate production line manufactured by aims for producing crushed stone aggregateConstruction Aggregate Crushing Plant Sep 01, 2020 The aggregate crushing plant is used by many industries in various production processes of specific raw materials These crushing plants use different equipment, like a prescreener, magnetic separator, loading conveyor, and crushing units, such as cone crushers and jaw crushers What Is Aggregate? Aggregate consists of a blend of minerals that are usually made up []What You Need To Know About The Aggregate Crushing Plant

AP42 Section 11192 Crushed Stone Processing and

crusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and the grizzly throughs (undersize material) are discharged onto a belt conveyor and usually are conveyed to a surge pile for temporary storage or are sold as coarse aggregates The stone from the surge pile is conveyed to a vibrating inclined screen called theAggregate Crushing Plant: A aggregate plant consists of many crushing and screening equipments For example, Aimix’s aggregate crush plant is composed of jaw crusher, cone crusher, impact crusher, sand making machine and vibratory sieve All these machines work in different crushing or screening processing stagesAggregate Crusher Turn Stone Materials into Building Flowsheet For Aggregates Crushing Plant Flow chart of three stage agreegate crushing plant to the most crushed coarse aggregate production plants, and the quaternary stage at the main task for the crushing equipment utilised in the rst three pro duction stages is The advantage of VSI crusher for the quaternary sand production stage is that it Flowchart of the air classiion experimentsFlowsheet For Aggregates Crushing Plant

SECTION 304 AGGREGATE BASE COURSE

required gradation, the Contractor may produce acceptable material in one operation or combine coarse and fine piles through a proportioning hopper to create a combined stockpile 323 Glass Cullet Crushing Plant 3231 The glass cullet crushing plant shall be capable of producing a product meeting the gradation requirements of AASHTO M 318Coarse crushed aggregate is commonly used in landscaping designs All aggregate is divided into two types: fine and coarse Fine aggregate is broken up into smaller pieces than coarse aggregate When put through a separator or aggregate washer, coarse crushed aggregate will pass through a 3inch (762cm) sieve but will not go through a No 4 What is Crushed Aggregate? (with pictures)According to the production capacity requirements rough crushing more than 1 200 t / h , the characteristics of Seven Trust materials containing more soil and the market demand for sand and gravel aggregate products, combined with the general map of the plant, the process layout, the coarse crushing equipment uses the rotary crushercoarse aggregate crushing plant price for sale in india

Mobile Aggregate/Sand Screening And Washing Plant 2020

Feb 01, 2021 Screening / Washing Plants Download Brochure Locate a Dealer Calculators Efficiently process aggregate material wherever opportunities exist with our portable Series 1800 screening and washing plants Our Series 1800 plants offer our industryleading fine material washer with an array of configurations — choose inclined or horizontal wet single, double or tripleshaft screens with two AGGREGATE CRUSHING VALUE This test helps to determine the aggregate crushing value of coarse aggregates as per IS: 2386 (Part IV) – 1963 The apparatus used is Cylindrical measure and plunger, Compression testing machine, IS Sieves of sizes – 125mm, 10mm and 236mm Procedure to determine Aggregate Crushing Value i)the aggregate crushing value of coarse aggregate which is The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an exampleaggregate crushing plant producer in

Parackal Rock Products

The crushing plant has undergone several stages of its renovation, currently installed with most modern machinery with a production capacity of 300 Tonne Per Hour (TPH) ENVIRONMENTAL CLEARANCE MOEF // OUR PRODUCTS Coarse Aggregate Different Sizes Available 40 mm Coarse Aggregate 32 mm Coarse Aggregate 20 mm Coarse Aggregate 12 mm Coarse Sepro Aggregate Systems designs and fabricates portable crushing plants that utilize Sepro equipment, other OEM equipment, or customer supplied crushing and screening equipment Plant design revolves around creating plants that are safe, easy to maintain and easy to configure for over the road towing with a minimum of disassembly requiredPortable Crushing Plants Sepro Aggregate SystemsThe crushing Plant has undergone several stages of its renovations, currently installed with most modern machinery with production capacity of 300 Tonne Per Hour (TPH) 20 mm Coarse Aggregate 12 mm Coarse Aggregate 6 mm Coarse Aggregate Plastering Sand The material is a finer grade sand with smaller particles Thus is used for Parackal

Diabase crushing plantDiabase sand making plant

The Basalt crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening The first stage: coarse crushing The diabase stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushingCrushing plant is also called crushing and screening plant, it includes sand and gravel production line, stone production line, silicon sand production line, construction aggregate production line Our stone crusher plant are engineered to deliver unrivaled productivity in Stationary Crushing Plant Aimix Concrete Batching PlantA stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt boulders Coarse aggregates are usually used in ready mix concrete and asphaltic concrete Crusher run is used for the bases and subbases for road makingEnvironmental GUIDELINE ON STONE CRUSHING plant

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumJan 26, 2016 This EXAMPLE Small Crushing Plant is designed to crush 500 tonnes per day, operating 12 hours per day with an availability of 70%The Plant will crush runofmine material (16″) to 100%, passing 5/8″ at a rate of 60 tonnes per hour Startstop stations are provided for all equipment in this Plant at the crusher control panel, to facilitate remote controlSmall Crushing Plant Operating GuidePrimary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be usedRock Crusher Eastman Rock Crusher

What is Crushed Aggregate? (with pictures)

Coarse crushed aggregate is commonly used in landscaping designs All aggregate is divided into two types: fine and coarse Fine aggregate is broken up into smaller pieces than coarse aggregate When put through a separator or aggregate washer, coarse crushed aggregate will pass through a 3inch (762cm) sieve but will not go through a No 4 According to the production capacity requirements rough crushing more than 1 200 t / h , the characteristics of Seven Trust materials containing more soil and the market demand for sand and gravel aggregate products, combined with the general map of the plant, the process layout, the coarse crushing equipment uses the rotary crushercoarse aggregate crushing plant price for sale in india 3000TPD Limestone Crushing Plant The limestone via feeder gets into HJ98 jaw crusher for coarse crushing, and through belt conveyor enters into PFW1214III hydraulic impact crusher for fine crushing And then vibrating screen sieve out material within 1030mm as coarse aggregate3000TPD Limestone Crushing Plant Industrial Technology

COARSE AGGREGATE (STONE) Crusher Mills, Cone Crusher

aggregate crushing plant,Coarse Aggregate Mills – Crusher Aggregate Crushing Plant Hello, welcome to understand our aggregate crushing plant and related stone crusher !Flowsheet For Aggregates Crushing Plant Flow chart of three stage agreegate crushing plant to the most crushed coarse aggregate production plants, and the quaternary stage at the main task for the crushing equipment utilised in the rst three pro duction stages is The advantage of VSI crusher for the quaternary sand production stage is that it Flowchart of the air classiion experimentsFlowsheet For Aggregates Crushing Plant