Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

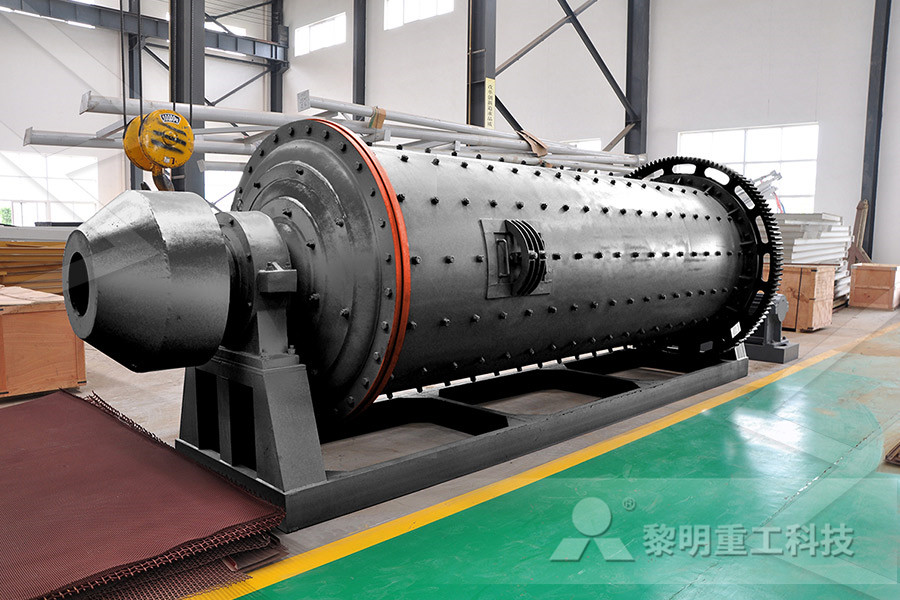

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Unit 16 Mine Development Mining and Blasting

Shaft Sinking Of all the headings driven in hard rock mines, shafts are the most costly and time consuming Moreover, the shaft sinking procedure is intricate and arduous While a few shafts are advanced by bighole drilling methods, the great majority use the traditional "drill and blast" cycle Shafts for smaller mines haveApr 17, 2020 Once the steps above are complete, the production step begins which includes two categories; surface mining and underground mining The surface mining the removal of the rock lying on the surface while underground mining requires digging What are the process stages of mining? Tech UpdateA deposit to be mined by underground methods can be accessed by a number of methods: • Adit • Decline or ramp • Inclined shaft • Vertical shaft Adits are an economical approach when the orebody is above the general floor elevation ie suitable in hilly or mountainous terrainMINE DEVELOPMENT – ACCESS TO DEPOSIT

STAGES IN THE LIFE OF A MINE Underground mining and

The five stages in the life of a mine are summarized in Table 13 and are discussed in the following sections There will be more extensive discussion of these stages in Chapters 2, 3, and 4 TABLE 12 Chronological Development of Mining Technologyunderground mining system is in the final stages of commissioning and will shortly be producing a nominal 30 000 tons per day with a predominantly automated system This paper discusses the complete stateofart shaft system developed for the Palabora underground mine, and refers particularly to the headgear, the winders, the conveyances and Stateofart shaft system as applied to Palabora Jan 01, 2019 A Lining Design Method Consistent With NATM for Deep Shafts Mine Hoist Plant Design Fundamentals An Innovative Approach to Shaft Sinking Stage (Galloway) Des The York Project: Shaft Sinking Mission 2021 – Reaching Poly Shaft Sinking in the Next Five Decades / 2070An Innovative Approach to Shaft Sinking Stage (Galloway

Sinking America’s Deepest Shaft E MJ

The crews sinking the shaft use a Galloway work stage, which allows the miners to do all of the work with a high degree of automation, withdraw during the blast, and The process of mining can be narrowed down to 6 essential steps Prospecting, Exploration, Planning, Development, Extraction, and Closure Furthermore, each step requires precision and perfection, making mining not only lengthy but also an expensive activity to undertakeWhat are the different stages of mining? Quoraactivities on the identification of hazards, risk s and their potential controls throughout the various stages of shaft construction This Guidance Note is not a Guideline as defined in the Mining and Quarrying Safety and Health Act 1999 (MQSHA) or a Recognised Standard as defined in the Coal Mining Safety and Health Act 1999 (CMSHA)Guidance Note QGN 30

An Innovative Approach to Shaft Sinking Stage (Galloway

Jan 01, 2019 A Lining Design Method Consistent With NATM for Deep Shafts Mine Hoist Plant Design Fundamentals An Innovative Approach to Shaft Sinking Stage (Galloway) Des The York Project: Shaft Sinking Mission 2021 – Reaching Poly Shaft Sinking in the Next Five Decades / 2070The five stages in the life of a mine are summarized in Table 13 and are discussed in the following sections There will be more extensive discussion of these stages in Chapters 2, 3, and 4 TABLE 12 Chronological Development of Mining TechnologySTAGES IN THE LIFE OF A MINE Underground mining and underground mining system is in the final stages of commissioning and will shortly be producing a nominal 30 000 tons per day with a predominantly automated system This paper discusses the complete stateofart shaft system developed for the Palabora underground mine, and refers particularly to the headgear, the winders, the conveyances and Stateofart shaft system as applied to Palabora

Case studies and analysis of mine shafts incidents in Europe

problem Shaft n°2 in VieuxCondé (France) is a 5 m diameter circular shaft, 501m deep It was filled in 1982 after the construction of a concrete plug at the bottom of the shaft Other stages of shaft were closed by various undefined remaining elements The follow up of the stowing shows that filling material volume is similar toShaft development rates are a function of diameter and ground conditions For 8 to 105ftdiameter shafts, which is the vast majority of what SDI does, they can complete a 500 to 800ft shaft in four to six months For 12to 15ftdiameter shafts, the development rate would be between five and seven monthsShaft Sinking Technology: The Long and the Short of ItDec 01, 2011 Murray Roberts Cementation has begun work on a contract awarded by Sasol Mining to provide a menandmaterial shaft and a ventilation shaft as well as a decline and coal seam development on the Underground Mine Development

Handbook to best practices for mine shafts protection

For abandoned mine shafts, some problems linked to deterioration of the sealing structure at the shaft head, or movement of backfilling material in the shaft have been observed It is also common to find mine shaft opened even decades after mining activity With time, it is also possible that mine shafts Shaft 1’s 750 m station will also allow access for the first raisebore shaft, which will have an internal diameter of six metres and provide ventilation to the underground workings during the mine’s rampup phase As shaftsinking advances, two additional shaft stations will be developed at mineworking depths of 850 m and 950 m Shaft 1 P4 intersects the Platreef Ivanhoe MinesApr 22, 2020 There can be a lot of development costs, such as building roads to get to the mine site, and sinking shafts, and removing something called overburden, which is the rock or soil that lies on top of a mineral deposit All of these costs are capitalized during the development stage Sustainable Production PhaseAccounting for Mining (#261) — AccountingTools

ISO/DIS 194261(en), Structures for mine shafts ? Part 1

remotely operated modular device used for loading blasted rock into a kibble (347) during mine shaft sinking operations, that is mounted within a stage (375) and comprises an extendable and articulating boom actuated with pneumatic or hydraulic cylinders to allow full range of motion within the blasting envelope and jaw buckets capable of The progress available with shaft sinking machines may be appreciated from the following performance of a machine manufactured by WIRTH, a leading manufacturer in West Germany In early 1983, one 7 m diam shaft was sunk in Alabama, USA, completing the sinking of the shaft, 650 m depth, in 6 weeks Sinking rate at one stage was 35 m/dayShaft Sinking Methods: Caisson Method and Cementation Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, usually those containing metals such as ore containing gold, silver, iron, copper, zinc, nickel, tin and lead, but also involves using the same techniques for excavating ores of gems such as diamonds or rubies Soft rock mining refers to excavation of softer minerals such as salt, coal Underground mining (hard rock) Wikipedia

Deep Thinking: Shaft Design and Safety for a New

The deepest shaft currently under construction, they said, is one for the Huaibei Coal Mining’s Xinhu mine in Anhui province, at 1,037 m depth and 81 m diameter Average shaft depths increased from less than 200 m during the country’s first FiveYear Plan (in the mid1950s) to over 570 m in the eighth (mid1990s), with 10% of all shafts Jan 01, 2019 A Lining Design Method Consistent With NATM for Deep Shafts Mine Hoist Plant Design Fundamentals An Innovative Approach to Shaft Sinking Stage (Galloway) Des The York Project: Shaft Sinking Mission 2021 – Reaching Poly Shaft Sinking in the Next Five Decades / 2070An Innovative Approach to Shaft Sinking Stage (Galloway Mar 28, 2017 Conventional mine shaft sinking methods involve the performance of a cycle of different operations—drilling and blasting, removal of smoke and cleaning of flyrock lodged on overhead timbers, mucking and hoisting of the broken rock, and timbering The latter (a) may be the last operation of the cycle, (b) may be carried on during drilling and mucking, provided it is done from a substantial Mine Shaft Sinking Methods 911 Metallurgist

ISO/DIS 194261(en), Structures for mine shafts ? Part 1

remotely operated modular device used for loading blasted rock into a kibble (347) during mine shaft sinking operations, that is mounted within a stage (375) and comprises an extendable and articulating boom actuated with pneumatic or hydraulic cylinders to allow full range of motion within the blasting envelope and jaw buckets capable of problem Shaft n°2 in VieuxCondé (France) is a 5 m diameter circular shaft, 501m deep It was filled in 1982 after the construction of a concrete plug at the bottom of the shaft Other stages of shaft were closed by various undefined remaining elements The follow up of the stowing shows that filling material volume is similar toCase studies and analysis of mine shafts incidents in EuropeDec 01, 2011 Murray Roberts Cementation has begun work on a contract awarded by Sasol Mining to provide a menandmaterial shaft and a ventilation shaft as well as a decline and coal seam development on the Underground Mine Development

Handbook to best practices for mine shafts protection

For abandoned mine shafts, some problems linked to deterioration of the sealing structure at the shaft head, or movement of backfilling material in the shaft have been observed It is also common to find mine shaft opened even decades after mining activity With time, it is also possible that mine shafts shafts are more often put down in soft rock and pass through faulted zones, whereas, the vertical shafts are usually in the firm wall rock However, in any well con structed shaft,where the walls are reasonably firm, shaft maintenance is a relatively small item of the mining expense and the lower first cost of the inclined shaft might easilySinking and equipping inclined shafts of more than 60 Mar 24, 2017 As it is difficult to sink the shaft while the mine is operating and it is expensive to setup for deepening the shaft, the initial sinking will often be to a depth that allows mining for the first How to build a mine

P4 intersects the Platreef Ivanhoe Mines

Shaft 1’s 750 m station will also allow access for the first raisebore shaft, which will have an internal diameter of six metres and provide ventilation to the underground workings during the mine’s rampup phase As shaftsinking advances, two additional shaft stations will be developed at mineworking depths of 850 m and 950 m Shaft 1 Mar 28, 2017 The subject of shaft sinking has been discussed at some length in an earlier Bureau of Mines bulletin A number of shaftsinking operations are described in detail in the series of information circulars on mining methods and costs, to some of which reference will be made laterMine Shaft Sinking Equipment 911 MetallurgistMay 26, 2016 DESIGN OF MINE SHAFTS Shafts play a major role in the general planning of mine development, their location is usually predetermined The location of a shaft can be changed when adverse geotechnical site conditions are encountered The design of mine shaft is an iterative process, which requires several variables and options to be considered in Shaft sinking 1 SlideShare

Shaft construction QueensMineDesignWiki

Shaft construction A shaft is defined as a vertical or inclined permanent opening that gives access and services various levels of a mine Shafts are designed according to their required purpose and depending on the demands set out Types Shafts can be either vertical or inclinedOne of PCS’s 65,000 lbs stage winches that was used in the sinking of the shaft was utilized as the primary winch to pull up the new ropes from the potash level As the underground work area was accessed by going underground at shaft #2, followed by a 45minute commute to the work area, staggered crew start times were utilized to have work Fortis Mining Engineering and Manufacturing Mine Hoist Underground Mining–Shaft Equipment 621 DRUMS AND SHEAVE WHEELS Drums and sheave wheels should be designed and manufactured in accordance with AS 3785 Underground Mining–Shaft Equipment 622 FENCING, GATES, SHAFT ENTRANCES SUPPORTED All shaft entrances from the bottom of every shaft to the head sheaves should have properMinerals industry safety handbook Part 6