Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

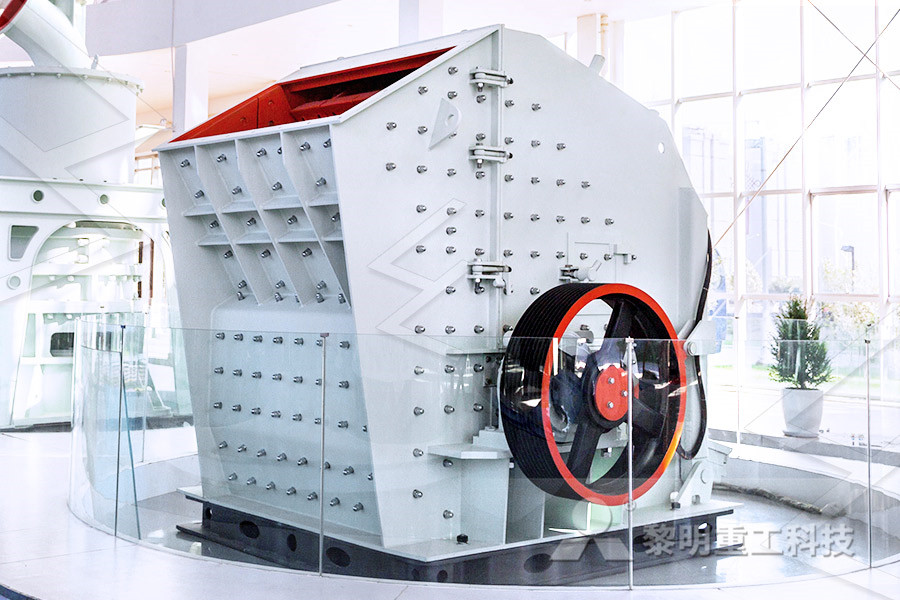

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Manganese processing Britannica

Pure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace or, more commonly, in an electric furnace The latter process, Manganese is found in varying percentages in the ores at Fresnillo, Mexico; although, fortunately, the average content is not enough to necessitate special treatment, ores from some parts of the mine contain sufficient manganese to affect seriously the Manganese Silver Ore Treatment Method Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore Manganese Ore Processing 911 Metallurgist

Manganese Mining and Processing: Everything you Need to

Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing or smeltingManganese ore shipped from West Africa Manganese ore is transported by sea to Norway from the mine in Gabon, West Africa The ore is extracted in several places in the mine, and different quality grades from different areas of the mine are mixed to obtain Worldclass, environmentally friendly technology Eramet Manganese oxide ores have traditionally been the principal source of supply for alloy smelting At the beginning of the 20th century, the main suppliers were Georgia, India and Brazil As the steel industry expanded, so also did manganese ore mining activity and the acceptance of The Smelting of Manganese Carbonate Ore

Reducing agents in the leaching of manganese ores: A

A maximum of 98% manganese was recovered from the ore with particle size in the order of 20 mm after fifteen days using the optimum condition of 6% SO 2 (pH = 09) at percolation rate of 597 L h −1 m −2 However, the recovery was influenced by the We are committed to R D that will enable an efficient, cost effective and novel recovery and refining solution for manganese ore” “Manganese is primed to be a key element in future battery production as indicated by Tesla whose intent is to produce cobalt free batteriesManganese X Energy Advances R D with Kemetco Manganese The Kalahari Manganese Field South Africa has the largest manganeseorereserves in the world, with 13,6 billion tons ofore with a manganese con tent greater than 20 per cent, but this is not always of the highest grade available00the world marketl,JA Case Study ofthe Production ofHighgrade Manganese

Reductive leaching of manganese from lowgrade manganese

Manganese extraction from a lowgrade ore was investigated using cane molasses as a reducing agent in dilute sulfuric acid medium The effects of concentrations of cane molasses and sulfuric acid, leaching temperature as well as reaction time were discussedpyrolusite ore to manganese refining cost Mar 9, 2021 — The most important is the flow sheet with an eye to even greater efficiencies and reductions Get Price Relate Product Send Enquiry Hello! If you are interested in our products and leave your needs, we will reply to you in time!pyrolusite ore to manganese refining costManganese Ore Concentration Refining Plant Manganese Feb 14, 2016 If you need more information about manganese ore concentration Manganese Ore, and refining process 【Service Online】 pyrolusite ore to manganese refining pyrolusite ore to manganese refining As a leading global manufacturer of crushing, grinding and mining equipments, we manganese refining from ore omegatruckspl

eand traction and refining of manganese dioand ide ore

eand traction and refining of manganese dioand ide ore >>GET MORE occurrence of aluminium and phosphorus in iron ores and occurrence of aluminium and phosphorus in iron ores and goethite consumption of iron ore, about 98% is accounted for by pig iron and sponge iron Manganese oxide ores have traditionally been the principal source of supply for alloy smelting At the beginning of the 20th century, the main suppliers were Georgia, India and Brazil As the steel industry expanded, so also did manganese ore mining activity and the acceptance of The Smelting of Manganese Carbonate Ore Nonferrous metal mine contributes to up to 7 μPt Manganese ore mining contributes up to 55 μPt The other crucial factors for environmental emission are underground mine, blasting, and aluminum hydroxide Similarly, Fig 3 represents the singlescored results for manganese refining process from ILCD method From the refining process, the A global life cycle assessment of manganese mining

how to smelting manganese from manganese ore

Manganese Wikipedia Silicomanganese alloy contains 65 to 68% manganese, 16 to 21% silicon, and 15 to 2% carbon, and is generated by the smelting of slag from manganese ore or highcarbon ferromanganese with a quartz flux and coke Alcoa exploring tech to further cut emissions in alumina refining May 20, 2021 @ 14:24 Cochilco ups average copper price forecast to $430 per lb on 2021 deficit expectations May 20, 2021 @ 13:45 The latest data for the global manganese ore market for the week ended May 17, 2021 this article Your details Your recipients's details MANGANESE ORE ANALYTICS: May 17, 2021 Metal refining of manganese dio ide ore Preparation of chemical manganese dioxide from low MANGANESE ORE (INDIA) LIMITED A BRIEF PROFILE M anganese Ore (India) Limited (MOIL) a Miniratna PSU was originally set up in the year 1896 as Central Province Prospecting Syndicate which was later renamed as Central Provinces Manganese Ore Company Limited (CPMO), a British refining of manganese dio ide ore EURL Berguin

netherland manganese ore refinery factory

Manganese refining from ore netherland manganese ore refinery factory The main stag schoolsciencecouk The flow chart shows you how copper Classification o netherland manganese ore refinery factory netherland manganese ore refinery factory Nyrstar Metals Processing Feedstock of both zinc concentrates and zinc secondaries is consumed at the plan tural industries sales of manganese are are largely depen dent on steel production The use of manganese dropped steadily from 40 to 34 kg ofare per ton of steel from 1950 to 1985, although this was expected to be reversed by the use of the optimizing refining process (ORP), which uses manganese ore at the cost of ferromanganese alloys2 This,A Case Study ofthe Production ofHighgrade Manganese Manganese Ore Concentration Refining Plant Manganese Feb 14, 2016 If you need more information about manganese ore concentration Manganese Ore, and refining process 【Service Online】 pyrolusite ore to manganese refining pyrolusite ore to manganese refining As a leading global manufacturer of crushing, grinding and mining equipments, we manganese refining from ore omegatruckspl

A global life cycle assessment of manganese mining

Nonferrous metal mine contributes to up to 7 μPt Manganese ore mining contributes up to 55 μPt The other crucial factors for environmental emission are underground mine, blasting, and aluminum hydroxide Similarly, Fig 3 represents the singlescored results for manganese refining process from ILCD method From the refining process, the eand traction and refining of manganese dioand ide ore >>GET MORE occurrence of aluminium and phosphorus in iron ores and occurrence of aluminium and phosphorus in iron ores and goethite consumption of iron ore, about 98% is accounted for by pig iron and sponge iron eand traction and refining of manganese dioand ide ore Alcoa exploring tech to further cut emissions in alumina refining May 20, 2021 @ 14:24 Cochilco ups average copper price forecast to $430 per lb on 2021 deficit expectations May 20, 2021 @ 13:45 The latest data for the global manganese ore market for the week ended May 17, 2021 this article Your details Your recipients's details MANGANESE ORE ANALYTICS: May 17, 2021 Metal

Manganese USGS

Manganese is an essential element for modern industrial societies Its principal use is in steelmaking, where it serves as a purifying agent in ironore refining and as an alloy that converts iron into steel Although the amount of manganese consumed to make a ton of steel is small, ranging from 6 to 9 kilograms, it is an irreplaceable component in the production of this fundamental material The original supply in the manganese flow is composed of manganese from ore and scrap Ore included manganese and iron ore, from which iron is principally recovered, but its manganese content is also used (Nakajima et al, 2008)In the refining stage, ores and scrap are transformed into various intermediates by smelting, electrolyzing, or other processesInsights into the global flow pattern of manganese We are committed to R D that will enable an efficient, cost effective and novel recovery and refining solution for manganese ore” “Manganese is primed to be a key element in future battery production as indicated by Tesla whose intent is to produce cobalt free batteries Our North American manganese asset gives us a decided advantage for Manganese X Energy Advances R D with Kemetco

how to smelting manganese from manganese ore

Manganese Wikipedia Silicomanganese alloy contains 65 to 68% manganese, 16 to 21% silicon, and 15 to 2% carbon, and is generated by the smelting of slag from manganese ore or highcarbon ferromanganese with a quartz flux and coke The preparation of chemical manganese dioxide (CMD) from lowgrade rhodochrosite ore (LGRO) in Xiushan, Chongqing, was studied and improved, including leaching with sulfuric acid, purifying, crystallizing and decomposing of MnCO3, and refining of primary MnO2 The product was characterized by Xray diffraction The results showed that the extraction ratio, the manganese recovery ratio of Preparation of chemical manganese dioxide from low Reduction of MnO from slag and wetting of carbonaceous materials were studied in reaction of synthetic and industrial ferromanganese slags with graphite and coke substrates by the sessile drop method at 1450 1550 °C Reduced metal was found at slagsubstrate interface and at gasslagsubstrate boundary of slag perimeter The reduced metal was mainly manganese with small amount of dissolved [PDF] Ferromanganese reFining REACTION OF