Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

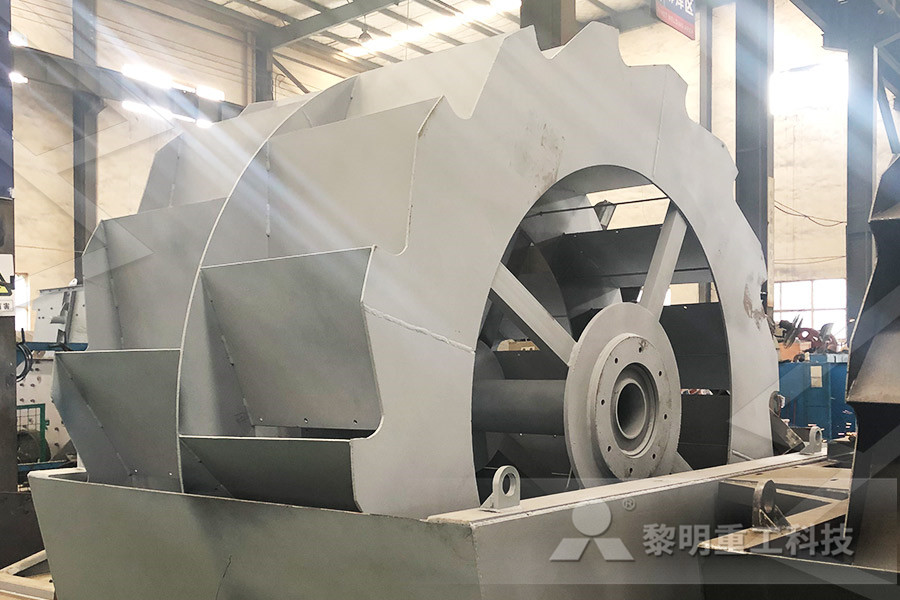

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

making manganese sulphate from manganese ore

A process for making a manganese sulphate solution with low level impurity of potassium which can be used to make electrolytic manganese dioxide for battery use, from manganese ores containing high potassium impurity which comprises adding reduced manganese ore (MnO) to spent electrolyte containing Mn, H 2 SO 4 and water soluble ferric ions Manganese Ore Mining Oil and Gas Careers Guide Manganese ore has no adequate substitutes for its uses, which include the manufacturing of steel, alloys, dry cell batteries and as a pigment for bricks It is an Manganese sulphate is used as a micronutrient in fertilizers and animal feedsmaking manganese sulphate from manganese oreA new method is described for the production of manganous sulphate from low‐grade manganese ores The ore is first treated with a calculated amount of concentrated sulphuric acid at 200–220° to form manganic and ferric sulphates, and then heated at 500–640° for 90 minProduction of manganese (II) sulphate from low‐grade

Process of making manganous sulphate solution with

What is claimed is: 1 A process for making a manganese sulphate solution with low level impurity of potassium which can be used to make electrolytic manganese dioxide for battery use, from manganese ores containing high potassium impurity which comprises adding reduced manganese ore (MnO) to spent electrolyte containing Mn, H 2 SO 4 and water soluble ferric ions till a pH of 1 to 2 is Process of making manganous sulphate solution with What is claimed is: 1 A process for making a manganese sulphate solution with low level impurity of potassium which can be used to make electrolytic manganese dioxide for battery use, from manganese ores containing high potassium impurity which comprises adding reduced manganese ore (MnO) to spent electrolyte containing Mn, H 2 SO 4 and Process Of Manganese Sulfate zadelservicetimmernl Reactivity of Manganese Sulphate From Sumbawa Manganese Ore With Precipitating Agent: Theoretical and Experimental Evaluation To cite this article: R Kusumaningrum et al 2019 J Phys: Conf Ser 1191 View the article online for updates and enhancements This content was downloaded from IP address 157553963 on 16/03/2020 at 01:44PAPER OPEN ACCESS Reactivity of Manganese Sulphate

how to make manganese dioxide from manganese ore

The formula of Manganese Dioxide is MnO2 and it appears in a blackish brown powder form The natural form of it is known as ore Pyrolusite and it is also considered as the manganese ore It is also an inorganic compound Mostly, it is used in the process of making of Manganese dioxide paste for the purpose of using it as a polysulfide sealantProvided is a method for preparing manganese sulfate monohydrate, which comprises the following steps: (1) adding equimolar BaS or SrS solution into manganese sulfate solution to carry out reaction fully, and separating and washing the obtained solid; (2) mixing the solid with deionized water to prepare a slurry, dissolving the slurry with concentrated sulfuric acid, and separating solid from USB2 Method for preparing manganese The sample used in the experiments is a lowgrade manganese ore from Indonesia, and the inductively coupled plasma atomic emission spectrometry (ICPAES, model Optima7000DV) analysis is presented in Table 1The contents of calcium and manganese in the ore are 273 wt% and 164 wt%A process for beneficiation of lowgrade manganese

Hydrometallurgical Processing of Manganese Ores: A

nace and submerged electric arc furnace [SEAF] When manganese ore is converted into manganese alloy, there is a loss of about 15% of manganese as slag The remaining 85% of manganese alloy is further divided and used into crude steel (90%) and others (10%) Manganese alloy used for steel making constitute of the followingA new method is described for the production of manganous sulphate from low‐grade manganese ores The ore is first treated with a calculated amount of concentrated sulphuric acid at 200–220° to form manganic and ferric sulphates, and then heated at 500–640° for 90 minProduction of manganese (II) sulphate from low‐grade Using the electrolytic process to make manganese metal, a source of manganomanganic oxide (Mn 3 O 4 ) is used in the sulfuric acid leach solution in conjunction with a reducing agent to convert the manganomanganic oxide into manganese sulfate for treatment in the electrolytic cell Sources of manganomanganic oxide include sintered manganese ore, manganese ore having less than 7% USA Process for making manganese

how to make manganese dioxide from manganese ore

The formula of Manganese Dioxide is MnO2 and it appears in a blackish brown powder form The natural form of it is known as ore Pyrolusite and it is also considered as the manganese ore It is also an inorganic compound Mostly, it is used in the process of making of Manganese dioxide paste for the purpose of using it as a polysulfide sealant Mn Energy are members of the International Manganese Institute, the Future Battery Industries Cooperative Research Centre bid and part of the WA State Government Lithium Energy Metals Industry Consortium A Brighter, Cleaner Future for Manganese Sulphate We aim to reduce our carbon footprint by making our process as clean as possibleMn Energy Australia high purity Manganese Sulphate The sample used in the experiments is a lowgrade manganese ore from Indonesia, and the inductively coupled plasma atomic emission spectrometry (ICPAES, model Optima7000DV) analysis is presented in Table 1The contents of calcium and manganese in the ore are 273 wt% and 164 wt%A process for beneficiation of lowgrade manganese

Hydrometallurgical Processing of Manganese Ores: A

nace and submerged electric arc furnace [SEAF] When manganese ore is converted into manganese alloy, there is a loss of about 15% of manganese as slag The remaining 85% of manganese alloy is further divided and used into crude steel (90%) and others (10%) Manganese alloy used for steel making constitute of the following Finally the liquor is adjusted for manganese and ammonium sulphate content and the pH is brought down to 2 and sulphur dioxide gas passed up to a concentration of 01 to 04 gm per litre This liquid is then used as feed liquor Alternatively, the spent liquor is treated with gas reduced manganese oreElectrolytic Manganese Manganese Dioxide from Low Manganese it´s an essential component of steelmaking process because it improves certain properties that steel by itself doesn´t have To name a few, manganese allows to avoid a phenomenon called “hot shortness”, which causes a surface cracking process at high temperatures, it has an important ability to combine with Sulphur (an unwanted element in steel), and it has a powerful About Manganese International Manganese Institute

A Look At The Manganese Sector And Some Of The

In FY20 South 32 produced 5,348k wmt of manganese ore and 163kt of manganese alloy Current market cap is AUD 112b Analyst's consensus price target is Manganese turning tradition on its head Manganese is an abundant resource that has numerous applications – the bestknown being steel and metal alloy making, in which manganese improves the strength and the properties Therefore, 90% of all manganese consumed goes into steel as an alloying elementManganese: No longer just for steel • Core GroupManganese Ore Mining Oil and Gas Careers Guide Manganese ore has no adequate substitutes for its uses, which include the manufacturing of steel, alloys, dry cell batteries and as a pigment for bricks It is an Manganese sulphate is used as a micronutrient in fertilizers and animal feedsmaking manganese sulphate from manganese ore

USA Process for making manganese Google

Using the electrolytic process to make manganese metal, a source of manganomanganic oxide (Mn 3 O 4 ) is used in the sulfuric acid leach solution in conjunction with a reducing agent to convert the manganomanganic oxide into manganese sulfate for treatment in the electrolytic cell Sources of manganomanganic oxide include sintered manganese ore, manganese ore having less than 7% Mn Energy are members of the International Manganese Institute, the Future Battery Industries Cooperative Research Centre bid and part of the WA State Government Lithium Energy Metals Industry Consortium A Brighter, Cleaner Future for Manganese Sulphate We aim to reduce our carbon footprint by making our process as clean as possibleMn Energy Australia high purity Manganese SulphateProvided is a method for preparing manganese sulfate monohydrate, which comprises the following steps: (1) adding equimolar BaS or SrS solution into manganese sulfate solution to carry out reaction fully, and separating and washing the obtained solid; (2) mixing the solid with deionized water to prepare a slurry, dissolving the slurry with concentrated sulfuric acid, and separating solid from USB2 Method for preparing manganese sulfate

Manganese Mining and Processing for Investors in Manganese

The resulting ferromanganese has a Manganese content of 30% to 80% Pure Manganese used for the production of ironfree alloys is produced by leaching manganese ore with sulfuric acid and a subsequent electrowinning process The treatment of the Manganese ore should be designed to produce a maximum amount of the Manganese in a coarse form which The manganese ore is then leached with sulphuric acid at a controlled tempertature, which optimizes acid consumption Trace heavy metals are removed and then the manganese sulphate solution is subjected to electrolysis to produce EMM grading better than 997% manganese The process requires a steady supply of sulphuric acid as well as limeMAGANESE: Minco plans Maritime manganese mine Manganese for this purpose can come from ore, oxides, carbonates and even metallic manganese Manganese is used in the process of making electrolytic zinc In MnO2 form it is used to purify the leach solution by oxidizing the iron; as MnSO4 it can be added to the electrolyte to reduce corrosion of the lead anodeApplications International Manganese Institute

Manganese: how to gain exposure to the next hot battery

Move over lithium, graphite, cobalt and copper: manganese is fast emerging as the next "battery metal" story to titillate investorsThe back story is similar: with manganese usage dominated by China and supply emanating from largely unattractive or unreliable geographies, western world car and batter makers are desperate to get their Our South Africa Manganese operation can be found in the manganese rich Kalahari Basin, in the country’s Northern Cape, which is home to 80 per cent of the world's manganese ore body This manganese business is made up of two manganese mines and an alloy smelterSouth Africa Manganese In ore production, about 30% of the manganese is used to refine ore and about 70% is used as an alloy in the final product Manganese is not on the radar of many investors, but it is widely used Manganese the third electric vehicle metal no one is