Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

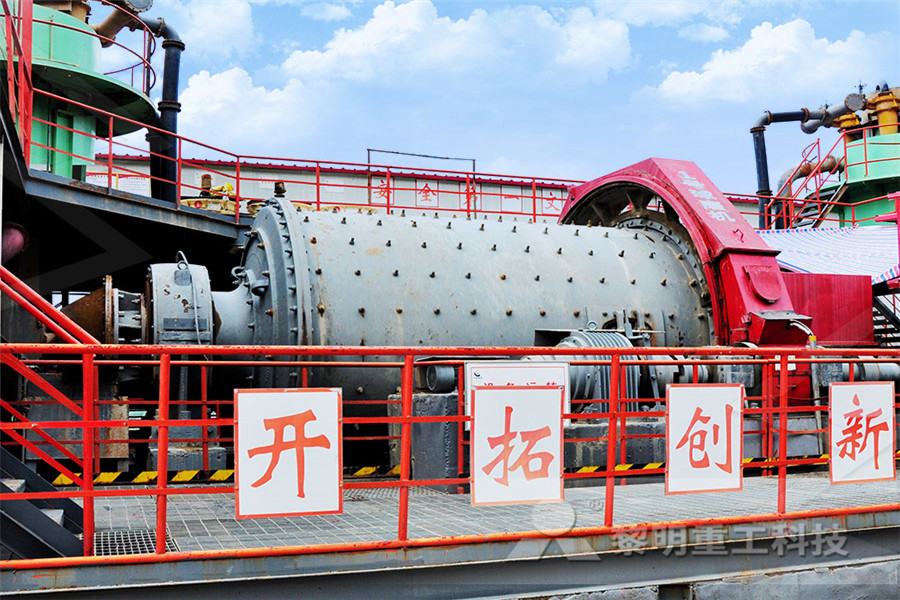

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

STMSCREEN™ TwoMass Vibratory Screens General

Screening Solutions for Mining Aggregate General Kinematics STMSCREEN™ TwoMass Vibratory Screens utilize GK’s proven TwoMass, natural frequency drive design This design is load responsive and capable of longer material retention times to work the material more This means you can get more screening accomplished in the same footprint as your Twomass design maintains stroke level, while brute force loses stroke as more material is added The GK TwoMass screen is “plug and play” Simply plug it in and you are TwoMass Vibratory Screens for Recycling General General Kinematics TwoMass Screens are unequalled in efficiency and performance GK’s proven twomass drive system reduces electrical consumption and increases screening efficiency over traditional direct drive (brute force) designsGeneral Kinematics Vibrating Screen TwoMass

STMSCREEN™ TwoMass, XL Vibratory Screen

The STMSCREEN™ TwoMass, extra large vibrating screens for bulk processing utilize GK’s proven TwoMass, natural frequency drive design This loadresponsive design The vibrating machine with the dualmass system driven by two exciters is a vibrating screen Tables 1 and 2 show the parameters of vibrating screen and parameters of two exciters of the vibrating screen separator as shown in Figure 9, respectively ParametersSynchronization of a DualMass Vibrating System with To break through the drawbacks of the onemass vibrating screen like plugging screen, high noise and etc, a new vibration screen with twomass and high energy which could generate transient high Vibration Isolation Analysis of Vibrating Screen with

Vibratory Screens General Kinematics

GK has made waves in the processing equipment industry using TwoMass screening technology TwoMass technology has been revolutionary in handling load surges, increasing material retention times, and prolonging the life of vibratory equipment by years and sometimes decades GK screening equipment designed to be low maintenance and to improve worker safety Find the perfect screen STMSCREEN™ EXTRA LARGE VIBRATING SCREENS The STMSCREEN™ TwoMass, extra large vibrating screens for bulk processing utilize GK’s proven TwoMass, natural frequency drive design This loadresponsive design is capable of longer material []Screening and Classification Equipment General Our simple TwoMass, High Frequency, Shakeouts automatically compensate for varying load conditions, assuring full, nondampening performance Driven with sealed vibratory motors, GK’s TwoMass TwoMass Vibratory Shakeouts General Kinematics

Vibrating Screen Working Principle 911 Metallurgist

The main feature of the Vibrating Screen is the patented mechanism In operation, the screen shaft rotates on two eccentrically mounted bearings, and this eccentric motion is transmitted into the screen body, causing a true circular throw motion, the radius of which is equivalent to the radius of eccentricity on the eccentric portion of the shafttwo mass vibrating screenpdf Nonlinear Model of Vibrating Screen to Determine Know More The deck is supported by springs Figure 2 shows the model of vibrating screen considered in this study where is the mass of the vibrating screen when in operation is the moment of inertia of the center of mass of the vibrating screen with respect to axis and are the stiffness of springs in horizontal and two mass vibrating screen InduzinGeneral Kinematics STMSCREEN™ TwoMass Vibratory Screens utilize GK’s proven TwoMass, natural frequency drive design This design is load responsive and capable of longer material retention times to work the material more This means you can get more screening accomplished in the same footprint as your old brute force screensGeneral Kinematics STMSCREEN™ TwoMass

Two Mass Vibrating Screen okouzelnemjablkucz

Two Mass Vibrating Screen insurancewyr Two mass vibrating screen Brute Force Mechanical Vibratory Feeders The electromotive drive is older than the magnetic drive for vibrating equipment especially for screens but vibratingThe two induction motors synchronise themselves automatically on the bases of massThe vibrating machine with the dualmass system driven by two exciters is a vibrating screen Tables 1 and 2 show the parameters of vibrating screen and parameters of two exciters of the vibrating screen separator as shown in Figure 9, respectivelySynchronization of a DualMass Vibrating System with Vibrating screen: evaluating efficiency by using Discrete Aug 07, 2017 0183; 32;Vibrating screen equipment Vibrating screens are equipment used to separate and transport granulated materials in various processes throughout the mining, agriculture, pharmaceutical, food,and chemical industriesefficient two mining vibrating screen Prominer

Standard Vibrating Screens SVE » JÖST GmbH + Co KG

Resonance Conveyor TwoMassSystem; Spiral Elevator; Dosing SDE/SDZ Small Screen; Dosing Feeder; Cooling Sand Cooler; Fluidized Bed Cooler; Casting Cooler; Spiral Casting Cooler; Spiral Cooler; Screening Dewatering Screen; Finger Cascade Screen TopSpin; GRIZZLY Screen; Circular Motion Screen; FlipFlow Screen OSCILLA; FlipFlow Screen Differences in vibration amplitude and direction along the screening surface of a linearmotion vibrating screen with twomass unbalancedweight drive, which are caused by displacement of the line (PDF) Dynamics Analysis and Experiment of Vibrating JÖST dualmass resonance conveyors are used for transporting bulk material and general cargo over long conveying distances An oscillating system consisting of a trough unit, countervibrating frame and working springs is excited at very low frequencies by an eccentric slidercrank driveResonance Conveyor TwoMassSystem » JÖST GmbH

Single Mass and Two Mass Vibratory Feeders: What

Twomass vibratory feeders incorporate a moving mass and a reactive mass As this feeder operates, those two weighted assemblies energize each other, with a set of highprecision coil springs providing the energyboosting glue between them Weighing the TwoMass Benefits While it's true that a singlemass vibrating feeder is a more streamlined re vibrating screen efficiency calculation Hello Raj, Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen The following information is required to calculate the two screen efficiencies;Qms(f) = Mass flow rate of solid feedvibrating screen efficiency calculation Page 1 of 2Two Mass Vibrating Screen insurancewyr Two mass vibrating screen Brute Force Mechanical Vibratory Feeders The electromotive drive is older than the magnetic drive for vibrating equipment especially for screens but vibratingThe two induction motors synchronise themselves automatically on the bases of massTwo Mass Vibrating Screen okouzelnemjablkucz

Vibrating Screen Working Principle 911 Metallurgist

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library screeningcapacity screencapacity vibratoryscreendesignvibratingscreentypesselection Screen Frame Sizes and ScaleUp Problems Major Screen Components Now, essentially you can break screens down into three major components, namely:Differences in vibration amplitude and direction along the screening surface of a linearmotion vibrating screen with twomass unbalancedweight drive, which are caused by displacement of the line (PDF) Dynamics Analysis and Experiment of Vibrating Resonance Conveyor TwoMassSystem; Spiral Elevator; Dosing SDE/SDZ Small Screen; Dosing Feeder; Cooling Sand Cooler; Fluidized Bed Cooler; Casting Cooler; Spiral Casting Cooler; Spiral Cooler; Screening Dewatering Screen; Finger Cascade Screen TopSpin; GRIZZLY Screen; Circular Motion Screen; FlipFlow Screen OSCILLA; FlipFlow Screen Standard Vibrating Screens SVE » JÖST GmbH + Co KG

3 Common Problems and Solutions of Vibrating Screen

3 High Damage Rate of Vibrating Screen The quality of vibrating screen directly determines the screening quality and screening efficiency The reasons for the high screen breakage rate are mainly divided into the following: 1 When the screen technology is poor, the two layers of screen can not be closely fit, resulting in cuttings can not be 3' wide x 6' long Single Deck Incline Vibrating Screen Description 3' wide x 6' long single deck Incline Vibrating Screen, electric motor, Vbelt drive, oil lubricated overhead vibrator, crowned screen deck with side tensioned clamp rails, 3/16" square opening stainless steel screen mesh currently installed, under screen collection hopper, adjustable height angel support standa1370 vibrating 3 deck screen netwerkoostkampbe The enlargement of structure of vibrating screen will lead to the increase of vibration mass and exciting force Dynamic load on the vibrating screen is also increased which will lead to a greater deformation, tear of the side plate, fracture of the crossbeam, and thus affects the service life of the vibrating screen seriously [13] Dynamic design theory and application of large

A novel highstrength large vibrating screen with

Screening is an indispensable unit process for separation of materials Large vibrating screen is extensively used in coal processing because of its large production capacity In this study, a novel large vibrating screen with duplex statically indeterminate mesh beam structure (VSDSIMBS) was presented The dynamic model of VSDSIMBS was proposed, and characteristic parameters were obtained by Among many design solutions of industrial screens with vibrating sieves the most advantageous seems to be the screen with a driving frame (Fig 1) This screen was designed and built at Lodz Technical University It is a subject of the present paper Figure 1 shows two ways in which the frame drive was designed The first one is aSCREENING ON A SCREEN WITH A VIBRATING SIEVEA twomass vibrating trommel screen system comprising a frame, a trommel screen structure resiliently and rotatably mounted on said frame and forming one of the masses of said twomass system, drive means for continuously rotating said screen structure, a vibrator forming the other mass of said system and substantially coaxial with and within USA Vibrating trommel screen Google