Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

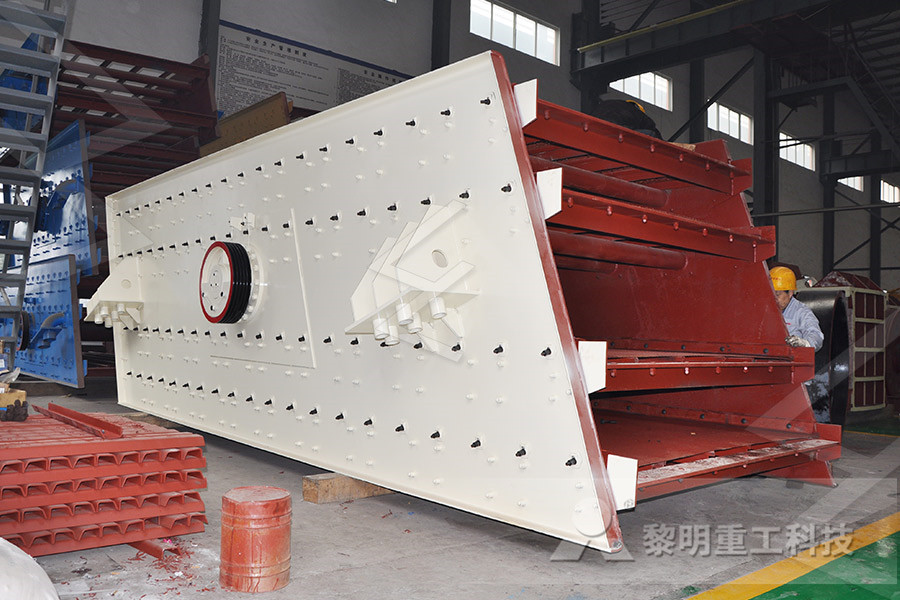

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Milling and grinding Malvern Panalytical

Milling processes span the gram to 100 t/h scale, while the need to track particle size from entry to exit demands a relatively broad size range The proven process interfaces built around the Malvern Panalytical Insitec sensors ensure an optimized solution for any applicationThe grinding principle of the Dinnox stainlesssteel mill is based on the Dinnissen hammer mill and is characterized by its very compact design, variable rotor speed and oneside bearing Thanks to this onesided bearing arrangement, the rotor can be completely Milling Grinding Process Technology Contact usToll Milling and Toll Grinding by Union Process assures the highest quality results as all work is done by skilled personnel who are extremely knowledgeable about the equipment In addition, Union Process operates a fully outfitted lab and pilot plant so testing can Toll Milling/Grinding Union Process

Grinding Machining Process : Complete Notes

In the grinding process, a layer of abrasive is responsible for removing the material from the work piece As machining starts, the abrasives of grinding wheel and work piece comes into contact and due to the rubbing force the initial layer from the grinding wheel is worn out and a fresh layer of the abrasives involve in machining this process Grinding of parts with very tight tolerances even with critical shapes (interrupted diameters, parts with holes, cuts, etc) Machine ready to work in infeed and/or throughfeed depending on the required production or part batches Noncontact measuring system, for flexibility and quick setup ESTARTA400 / ESTARTA650 Centerless grinding Valve Spools Machining Solutions DANOBAT grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10 • Determine the grinding force and force per grain • Determine the Grinding and Finishing IIT Bombay

Understanding the Milling Process MF

The cutting or grinding tool faces down against the workpiece surface to remove material Angular milling This milling method positions the cutting tool’s rotary axis at an angle to the workpiece surface to produce angular cuts as specified by the design, such as grooves or dovetails Form milling Form milling During machining through chip removal, a tool is used which comprises one or more blades This tool performs processes roughing and finishing During roughing the accuracy decreases, so the finishing process is used to complete the surface finish of Processes of milling, drilling, turning, brushing The process of roller milling involves separation of the endosperm from the bran and germ followed by gradual size reduction of endosperm (Ziegler Greer, 1971) Producing flour that fulfills the requirement for being whole grain is achieved by blending bran and germ back with the endosperm flour in the naturallyoccurring proportionsEffects of different milling processes on whole wheat

Laboratory Mill Lab Grinder Lab Grinding Mills

Lab Grinding Mills In a laboratory setting, most materials used for sampling are nonhomogeneous mixtures The best method of obtaining a small sample of these mixtures is to take a quantity of the material big enough to be compositionally representative, and then reduce it to a fine powder Manufacturing process We supply a complete manufacturing process including turning, milling, thermal deburring, grinding and chrome plating, from drawing to finished product One size technology Avoid color coding We will produce your product to your specification Read more>>>Karlsson Spools tillverkar cylindriska detaljer med hög The cutting or grinding tool faces down against the workpiece surface to remove material Angular milling This milling method positions the cutting tool’s rotary axis at an angle to the workpiece surface to produce angular cuts as specified by the design, such as grooves or dovetails Form milling Form milling makes nonflat cuts, such as Understanding the Milling Process MF

Grinding and Honing Rable Machine Inc

Grinding is most commonly used when a material is too hard to machine efficiently or when the tolerances required are too precise for machining Rable Machine's grinding capabilities including centerless grinding, through feed grinding, plunge form grinding, OD Grinding, ID grinding honing and surface grinding to be fabricated by using simple grinding wheels These shapes require threedimensional micro/nano machining using endmilling technologies Micro/nano machining process is performed under lower feed rates and smaller depths of cut compared with conventional machining Micromachining time is comparatively long, which requires long tool life Tool fabrication system for micro/nano milling function Current Process Biopsy needle notches are machined using milling, conventional abrasive grinding, or wire EDM Challenges Exposing the material to high heat can affect the chemistry and mechanical properties of the material requiring manual secondary finishing operations Setup and production are slow, requiring extensive mechanical adjustmentsMetal Grinding Applications Glebar Centerless

NonTraditional Processes (NTP) NONTRADITIONAL

– Process parameters: abrasive type, grit size, flow rate – Other parameters: Nozzle office diameter(025 to 063 mm) – Abrasives: aluminum oxide, silicon dioxide garnet – Standoff distance is ½ and ¼ of those of WJC • Abrasive Jet Machining (AJM) – Usually finishing process (deburring, polishing, cleaning) not cuttingThe turning process has developed itself continuously over the years and has taken precedence in the manufacture of much larger machines due to their much larger diameters In the first years, the chip removal process started only with straight shaft machining and today it Turning milling up to 4000mm length / Uzkar The result is a process that, given the right application, removes material 30 to 40 percent faster than traditional grinding, milling or EDMing, according to Kawasaki Better yet, burrs are minimal and there’s no heataffected zone as is the case with abrasive grinding and EDMingSharp attack: How needles and other medical sharps

Answering Five Honing FAQs Modern Machine Shop

The process is relatively slow as well Optimized milling processes followed by boring or reaming may produce highquality results, but not always consistently Honing achieves all three goals: That is, the process consistently and reliably achieves bore diameter tolerances of ±00002 inch or tighter with highquality surface finishesSpool Material General steel Previous Process Drilling Industry General Machinery Previous Process Grinding Industry Aerospace Ringshaped internal gear Material General steel Previous Process Face milling Industry Automotive Transmission case (Cross hole) Material Nonferrous metal Select by applications XEBEC TECHNOLOGY CO,LTD The cutting or grinding tool faces down against the workpiece surface to remove material Angular milling This milling method positions the cutting tool’s rotary axis at an angle to the workpiece surface to produce angular cuts as specified by the design, such as grooves or dovetails Form milling Form milling makes nonflat cuts, such as Understanding the Milling Process MF

Tool fabrication system for micro/nano milling function

to be fabricated by using simple grinding wheels These shapes require threedimensional micro/nano machining using endmilling technologies Micro/nano machining process is performed under lower feed rates and smaller depths of cut compared with conventional machining Micromachining time is comparatively long, which requires long tool life Current Process Biopsy needle notches are machined using milling, conventional abrasive grinding, or wire EDM Challenges Exposing the material to high heat can affect the chemistry and mechanical properties of the material requiring manual secondary finishing operations Setup and production are slow, requiring extensive mechanical adjustmentsMetal Grinding Applications Glebar Centerless The turning process has developed itself continuously over the years and has taken precedence in the manufacture of much larger machines due to their much larger diameters In the first years, the chip removal process started only with straight shaft machining and today it Turning milling up to 4000mm length / Uzkar

SABC Grinding Circuit 911 Metallurgist

To understand the need for a SABC Grinding Circuit it is pertinent to briefly describe the geology To obtain reliable results from the tests stable milling conditions were essential This involved monitoring parameters such as power draw, bearing pressure, feed rate and mill speed, and prescribing strict limits the first major process We had manufactured many spool and sleeve assemblies with various types of material but not with such tight tolerances Tolerances The process was very complex and included machining the parts, initial honing grinding, heat treat, final honing grinding and a matching process to complete each assemblyMatched Sets of Spools Sleeves Case HistoryNorcen: the choice for precision Metal Machining EDM Read More Milling Read More Turning Read More Whether your part is made from low carbon steel or the hardest of exotic alloys, Norcen Industries can machine any metal, including all classes of stainless steel, to tolerances as little as ± 0002″ Most []Metal Machining Norcen

Select by applications XEBEC TECHNOLOGY CO,LTD

Spool Material General steel Previous Process Drilling Industry General Machinery Previous Process Grinding Industry Aerospace Ringshaped internal gear Material General steel Previous Process Face milling Industry Automotive Transmission case (Cross hole) Material Nonferrous metal We process this product using sixspindle automatic lathe and pursue a differentiation from competitors by inhouse tool layout We can produce 450 pieces an hour Furthermore, we remove grinding burrs generated after grinding using barrel machine and applying rustproofing after washingList of productAVEX, Inc|Precision cutting/grinding Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to its versatility, capability, economy Mechanical deburring and edgefinishing processes