Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

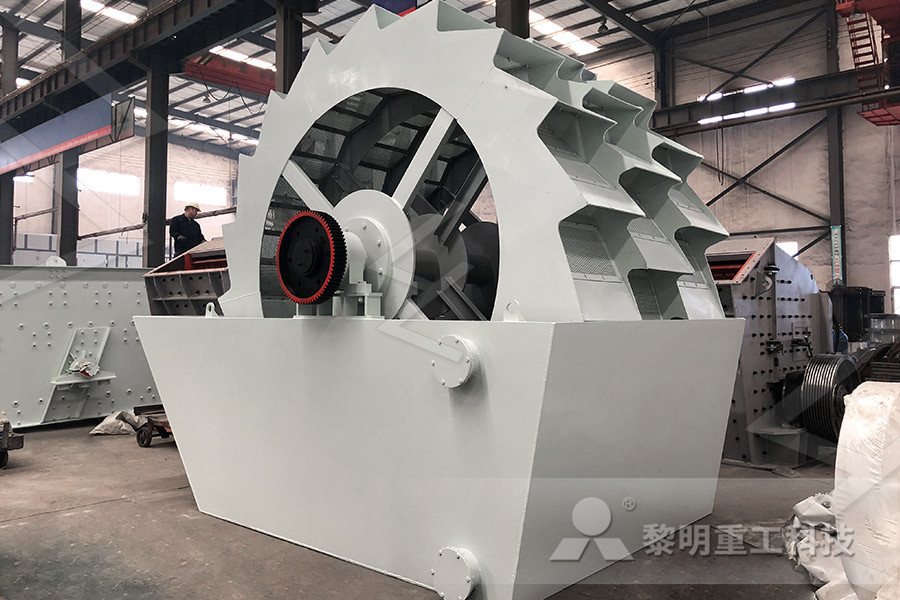

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Primary gyratory crusher parts Outotec

The primary crusher plays a crucial role in the size reduction process Even small improvements in uptime or throughput have a significant impact on the productivity of the entire operation Highquality primary gyratory crusher parts increase the crushing Gyratory Parts Of A Gyratory Crusher And Its Principle Of Operations Crusher Mainshaft Spare Parts put into use in order to ensure its operation principle of jaw crusher Sand making machine stoneComputer Aided Design of Jaw crusher ethesis NIT 1 3 Working Principle 5 1 6 Material for components of jaw crusher 11 Due to their simple design Operation And Parts Of Gyratory Crusher Home » Crusher Parts » Primary Gyratory Parts Primary Gyratory Parts by CMS Cepcor® The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory Primary Gyratory Parts Gyratory Crusher Parts CMS

Gyratory Crusher Components 911 Metallurgist

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system The base is the section of the crusher that provides an entry point for the drive assembly and oil Operation And Parts Of Gyratory Crusher Video Crusher Secondary breakers pit quarry equipment operations sep 02 2019 gyratory crusher a gyratory crusher uses a mantle that gyrates or rotates within a concave bowl as the mantle makes contact with the bowl during gyration it creates compressive force which fractures the rock the gyratory crusher is mainly used in rock that is abrasive andor has Operation And Gyratory Crusher Parts mizofootcarenlCommon gyratory crusher spare parts include: Gyratory Crusher Shells and Spider – Cast at some of the most advanced foundries in operation today Combined with modernday FEA (Finite Element Analysis) and highquality standards, today’s shells and spiders are prepared for years of serviceCrusher Spare Parts For Jaw, Cone Gyratory Crusher

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are operation and parts of gyratory crusher operation and parts of gyratory crusher SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratiooperation and gyratory crusher parts Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the Gyratory Crushers 911 Metallurgist

Gyratory Crusher Parts Mayang Crusher Parts

Gyratory crusher wear parts engineered for your unique needs We’re different from other vendors We’ll develop what you need Here’s what you get when you work with Mayang: Extensive experience with abrasion corruption resisting parts of mining industry around the world; Knowledgeable field service and engineering specialistsOur comprehensive range of replacement crusher parts to suit primary gyratories are certified to meet the OEM specification under our Lloyds Register quality system Furthermore, our premium range of primary gyratory crusher manganese steel and alloy castings are proven in mining and aggregate production applications worldwidePrimary Gyratory Parts Gyratory Crusher Parts CMS Operation And Parts Of Gyratory Crusher Video Crusher Secondary breakers pit quarry equipment operations sep 02 2019 gyratory crusher a gyratory crusher uses a mantle that gyrates or rotates within a concave bowl as the mantle makes contact with the bowl during gyration it creates compressive force which fractures the rock the gyratory crusher is mainly used in rock that is abrasive andor has Operation And Gyratory Crusher Parts mizofootcarenl

Construction, Working and Maintenance of Crushers for

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength The crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves foundry facility for EXCEL parts XL40 bronze components Quality and innovation Our compression crusher spare parts are designed to offer increased durability, smoother operation and reduced maintenance expenses, so that you can get your essential equipment up and running as quickly and effectively as possible Increase durability Spare wear parts for Gyratory Style Crushers Reliable high operation and parts of gyratory crusher operation and parts of gyratory crusher SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratiooperation and gyratory crusher parts

Gyratory Crusher Wear Plates

With the right Gyratory Crusher Wear Plates for your site and use case, you’ll find greater reliability in your equipment and you will keep productivity high Reduced OPEX Keep your machinery running longer and reduce operating expenditures with Gyratory Crusher Wear Parts made from the Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC Operation And Parts Of Gyratory Crusher 33 Views The is the professional mining equipments manufacturer in the world, located in China,India, along with other construction operation of a gyratory in wikipedia – Gold Ore gyratory crusher operation worldcrushers

Operating Principle Of Gyratory Crusher Crusher

Gyratory Crusher Parts,Gyratory Crusher Offers Manufacturers Gyratory Crusher Gyratory Crushing Principle Gyratory Crusher for primary crushing of iron low maintenance and operating cost Gyratory Crusher Applications Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and “ideal” fashionWorking Principle of Crushers 911 Metallurgist Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zonesCone Crusher Working Principle Animation

Gyratory Crusher Components 911 Metallurgist

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system The base is the section of the crusher that provides an entry point for the drive assembly and oil system It also provides support for the working surface of the main frame and linersOur comprehensive range of replacement crusher parts to suit primary gyratories are certified to meet the OEM specification under our Lloyds Register quality system Furthermore, our premium range of primary gyratory crusher manganese steel and alloy castings are proven in mining and aggregate production applications worldwidePrimary Gyratory Parts Gyratory Crusher Parts CMS foundry facility for EXCEL parts XL40 bronze components Quality and innovation Our compression crusher spare parts are designed to offer increased durability, smoother operation and reduced maintenance expenses, so that you can get your essential equipment up and running as quickly and effectively as possible Increase durability Spare wear parts for Gyratory Style Crushers Reliable high

HIGH PEFOMACE PATS Cone Crusher and Gyratory

Cone and Gyratory wear parts 3 Longer wear life for your crusher's parts Reduced downtime Lower operating costs Improved performance Minespeciifc design innovations Key benefits Standard bronze pour from furnace to ladel in our foundry for EXCEL parts XL40 bronze components Optimum concentricity • A 42inch gyratory crusher produces approximately 24 tons per horsepowerhour (29 t/kWh) • When idling jaw crushers consume approximately 50% of the power of full operation and gyratory approximately 30% •Installation of an underground jaw crusher may cost up to six times as much as the crusher itselfCrushers QueensMineDesignWiki But the daily operation and maintenance are more complicated than the jaw crusher Choose jaw crusher or gyratory crusher The general largescale crushing plant will choose the gyratory crusher as the primary crusher, except the viscous materials crusher plant Because the capacity of the gyratory crusher is large, Big crushing ratioDifference Between Jaw Crusher and Gyratory Crusher

operating principle of gyratory crusher crusher mills

Cone Crusher Working Principle Animation Engineering Intro Aug 15 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones Cone crusher parts More DetailThe gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect TopicsCrusher wear studies by Columbia Steel take the guesswork out of cone liner, jaw plate, and gyratory wear part choices, benefiting your operation with better production and less downtime Crusher OEMs generally offer a limited choice of wear part designs, and these are usually based on average conditionsCrusher Wear Studies for Better Productivity