Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

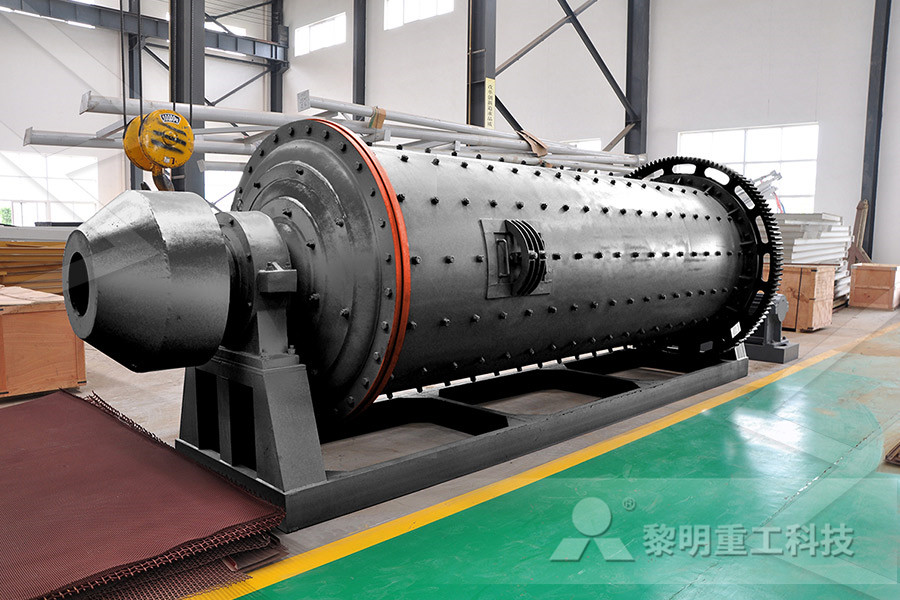

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Screw conveyor design calculation an Engineering Guide

Screw conveyor design : methods How to size a screw feeder ? Screw conveyors are among the most widespread equipment for transporting and dosing bulk solids It is thus required in many projects to calculate the size of a screw conveyor in order to reach a required capacity It can be also required to check the capacity of an existing screw in May 10, 2018 In contrast, the inlet of a screw feeder is always 100percent or flood loaded and typically mounted directly to a storage device such as a hopper, bin or silo The amount of material discharged by a screw feeder is completely controlled by design parameters A hopper is typically square or rectangular in shape with sloped bottom and limited storage capacityScrew Feeder Design for Metering Bulk MaterialsFeb 20, 2018 Basic Screw Feeder Design A screw is designed to move bulk materials from one flight to the next during every revolution Therefore, if the screw is 100 percent loaded and the capacity is the same for each flight, new material can only be introduced to the first flight under the storage device, opposite the discharge Screw Feeder Design for Metering Bulk Materials

How to Design Efficient and Reliable Feeders for Bulk Solids

The key to proper screw feeder design is to provide an increase in capacity in the feed direction [4] This is particularly important when the screw is used under a hopper with an elongated outlet One common way to accomplish this is by using a design as shown in Fig 1of screw conveyor trough and screw pitch kwS recommends designing screw conveyors using the lowest possible degree of incline for maximum efficiency The following are design and construction features to consider when designing an inclined screwENGINEERING GUIDE Screw Conveyors ManufacturerCalculations for screw conveyors Capacity in m2 per hour (Q) Q = 47,1 x ( D2 d2 ) s x n x i Capacity in kg per hour (Q) Q = 47,1 x ( D2 d2 ) s n x i sg D = screw outside diameter in dm d = screw inner diameter in dm s = pitch in dm n = rotations per minute sg = specifi c weight of the material (see table) Calculations for Screw conveyors Bechtel Wuppertal

screw feeder capacity output online Admin

screw feeder capacity output online baasrodeva be Screw feeder capacity output online enquiry cad Doc key words screw conveyor conveyor system the selection of the design get price screw conveyor capacity kws manufacturing capacity is defined as the weight or volume per hour of a bulk material that can be safely and feasibly conveyed using a • Screw Diameter = 635 mm • Channel Depth = 111 mm • Screw RPM = 80 • Root Temperature = 100 C • Screw Diameter = 635 mm • Channel Depth = 111 mm “An Experimental Investigation of Solids Conveying in Smooth and Grooved Barrel Single Screw Plasticating Extruders”, Conf Proceedings, ANTEC 98, pp 136141SCREW DESIGN BASICS TAPPIJan 11, 2007 If you are serious about wanting to design a screw feeder I would suggest that the first step is to decide on the flow regime that the feeder is to generate in the hopper see 'Educational Resources for Particulate Technology Vol 1, No 1,Art 3 (1999 Jan)'Twin Screw Feeder Design bulkonline

Design of Auger Type Feed Screw and its Casing for Food

the outlet of the feeder If the above parameters are not satisfying the conditions, then it will lead to undesirable results at the output Fig1 Auger type feed screw Continuous smooth flow of material is necessary at the output for proper extraction of the fed material And input material should not lose its shape and deformDec 16, 2018 conveyor design Screw feeders are popularly used for this control and are discussed in other pages of this catalog CLASSIFY YOUR MATERIAL Materials are classified in table No 6 on pages 12, 13 and 14 If your material is not listed, it can be classified by comparing it with similar materials that do appear in the table Screw Conveyor CorporationThe basic range of screw feeder application is 416mm total length of screw, 2380mm diameter and 0535mm thickness of nut Handheld automatic screw feeder is mainly used in electronic, plastic, toys, electrical equipment and communication equipment of automatic assembly lines, such as assembly lines of mobile phones, hard disks, keyboards Screw Feeder, Automatic Screw Feeder ATO

Automation Screw Driving Assembly Solutions Screw

Depending on your screws and the desired output, We can offer different we can design a highefficiency, userfriendly screw tightening solution according to customer's product requirements Choose the right material with right automatic screw feeder price ;The weighing screw machine, entirely made in stainless steel is complete with N°3 load cells and an encoder for the detection of weight and speed According to the clients need, the weighing screw can be customized and the diameter of the screw and the rotations can be modifyScrew feeder weighing machine PLPThis screwpresenter is especially well suited for countersunk screws A screwseparator sorts and presents each individual screw at a pickup position The screw is removed using an upwards motion A signaloutput allows the control of the pickup position by a host controller PDF Product Catalog D 3840Screw Presenter Feeding Technologies Screwdriving

Vertical Screw Conveyor Design Project

Oct 12, 2017 Vertical Screw Conveyor Design Project 1 MACHINE DESIGN MEX5277 VERTICAL SCREW CONVEYOR NAME : P A HEWAPATHIRANA REGISTER NUMBER : DATE OF SUBMISSION : 22/09/2017 CENTER : COLOMBO 2 i Table of contents List of Illustration ii Introduction iii Aim and Objective iv Specifications iv 1 Design Layout 1 2Mar 24, 2021 Jenike Johanson engineers have found that one key to proper screw feeder design is to provide an increase in capacity in the feed direction When a screw’s design or pitch tolerances do not provide this increasing capacity along the length of the bin outlet, a screw will tend to withdraw material only from one end of the outlet, usually the back endHow To Eliminate Screw Feeder Problems BulkInsideThe continuous weighing feeding devices can include pan or tube feeders, screw feeders and belt feeders Vibra Screw is the only manufacturer to offer a controlled vibration feeder design for weigh feeding, This means minimal loss of accuracy during the volumetric refill cycle and unprecedented accuracy in the gravimetric modeContinuous Loss In Weight Feeders Vibra Screw

Capacity Calculation for a Double Screw Conveyor

Oct 10, 2016 It is no task for amateurs to design equipment of this type Even with 'simple' screw conveyors, it has been pointed out that there are many variations of construction and duty Conveying, dispensing, feeding, elevating and screw hopper dischargers have different functions, objectives and work on a various different operating principlesGood quality screw feeder conveyor from screw feeder conveyor manufacturer, Buy screw feeder conveyor online from China PE PP Pellet Plastic Mixer Machine With High Output 8000KG Capacity Durable Plastic Mixer Machine Dry Powder Blender Four Wheel Upright DesignBuy screw feeder conveyor, Good quality screw feeder The machine consists of a Metering Screw Feeder, which pre conditions and meters the product by volume into a short weigh screw, turning at a variable speed through which the product is conveyed With the Weigh Screw located on a weigh platform the PLC provides a fail safe, positive indication of material flowrate change, variation in density Continuous Weighers Enclosed Weigh Screw

Maximizing Productivity for TwinScrew Compounding

polymer at side feeder with current screw design) Machine configuration includes multiple vent openings (upstream and downstream of side feeders) and these types of screw configurations designed to optimize fineparticle talc feeding and maximize machine capacityDec 01, 2017 With that data you can size the hopper for adequate capacity to service the extruder’s desired output and start to develop the crammer design To design the auger there are helpful tables of tubular screwconveyor data on the internet that take into account similar material characteristicsExtrusion: How Hopper Crammers Can Help Feeding Plastics the outlet of the feeder If the above parameters are not satisfying the conditions, then it will lead to undesirable results at the output Fig1 Auger type feed screw Continuous smooth flow of material is necessary at the output for proper extraction of the fed material And input material should not lose its shape and deformDesign of Auger Type Feed Screw and its Casing for Food

Loss in Weight Feeders Screw Feeders Rospen

Screw Feeders The lossinweight system is normally supplied with a standard Rospen metering screw feeder either single or twin screw from 12mm to 250mm dia and output range from 10kg/hr to, in excess of 100,000kg/hrThe basic range of screw feeder application is 416mm total length of screw, 2380mm diameter and 0535mm thickness of nut Handheld automatic screw feeder is mainly used in electronic, plastic, toys, electrical equipment and communication equipment of automatic assembly lines, such as assembly lines of mobile phones, hard disks, keyboards Screw Feeder, Automatic Screw Feeder ATODepending on your screws and the desired output, We can offer different we can design a highefficiency, userfriendly screw tightening solution according to customer's product requirements Choose the right material with right automatic screw feeder price ;Automation Screw Driving Assembly Solutions Screw

Bulk solids handling Engineering Feeder and Conveyor

Screw feeder and screw conveyor / auger design The efficient screw feeder and screw conveyor design requires in depth knowledge of bulk solids and powder flow properties and characteristics, as well as detailed design knowledge of the spiral or screw flight efficiencyThe weighing screw machine, entirely made in stainless steel is complete with N°3 load cells and an encoder for the detection of weight and speed According to the clients need, the weighing screw can be customized and the diameter of the screw and the rotations can be modifyScrew feeder weighing machine PLP28 A single screw feeder as a separate unit [22] 18 29 A single screw feeder with extension conveyor [22] 18 210 A test rig for screw feeders [81] 19 211 A experimental setup for screw feeders [77] 19 212 A twin screw feeder [22] 20 213 A typical form of screw feeder fitted with hopper Theoretical modelling and Research Online

Feeding Fasteners Fast Manufacturing automation and design

Apr 04, 2005 The specifications of screw presenters vary, but AIMCO's Acrafeed screw presenter is typical It feeds #0 to #10 screws with a maximum length of 3/4 inch The hopper holds 1,200 #4 screws Screw presenters don't have to be selfcontained systems Instead, a screw presenter mechanism can be attached to the output of a vibratory bowlOct 10, 2016 It is no task for amateurs to design equipment of this type Even with 'simple' screw conveyors, it has been pointed out that there are many variations of construction and duty Conveying, dispensing, feeding, elevating and screw hopper dischargers have different functions, objectives and work on a various different operating principlesCapacity Calculation for a Double Screw ConveyorDec 01, 2017 With that data you can size the hopper for adequate capacity to service the extruder’s desired output and start to develop the crammer design To design the auger there are helpful tables of tubular screwconveyor data on the internet that take into account similar material characteristicsExtrusion: How Hopper Crammers Can Help Feeding Plastics

Feeders powderbulksolids

A controlled vibration feeder design for weigh feeding means minimal loss of accuracy during the volumetric refill cycle and high accuracy in the gravimetric mode The versatile line of weigh feeding devices includes pan or tube feeders, screw feeders, and belt feeders Vibra Screw Inc, Totowa, NJ, 9732567410 vibrascrewApr 03, 2021 An automatic screw feeder machine is designed to feed smaller sized items such as screws, rivets and nails in a metered fashion Thus, one can control the pace at which the screws are supplied as well as the orientation in which they must be transferred along the Top Applications Of Automatic Screw Feeder Machine Design and Development of Material Feeder in MultiStation Application Screw feeder housing will be designed once the screw size and diameter is fixed Torque value calculation Material output: Soil material must be with squeezed and in clay form with water and additivesDesign and Development of Material Feeder in MultiStation

Industrial Screw Conveyors CustomBuilt Conveyor

This robust feeder is the perfect solution to give you years of consistent performance Designed for reliable, productive performance in even the most challenging conditions, our screw conveyors support business leaders in meeting their target output levels To begin integration of a screw conveyor within your facility, call our experts now