Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

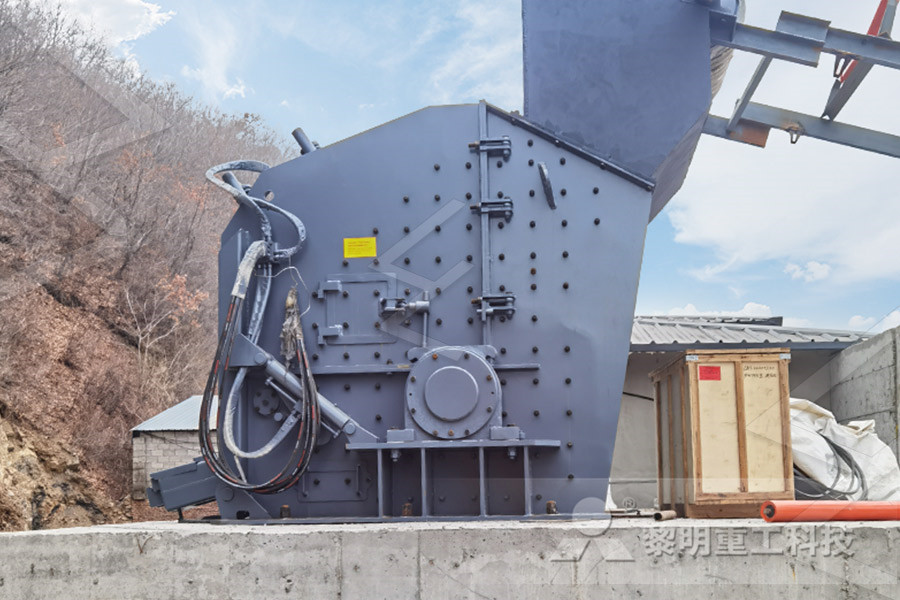

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Aluminum Cold Rolling Mills by Primetals Technologies

ALUMINUM COLD ROLLING MILL — A SINGLE HIGHPRECISION MILL FOR BOTH BREAKDOWN AND FINISHING Primetals Technologies' aluminum cold rolling mills offer a blend of innovative design and proven technology for both new and revamp projects This enables strip to be produced at very tight tolerances and productivity levels resulting in maximum yieldLaserSpeed Pro delivers a measurement accuracy of better than +/003% with +/002% repeatability, enabling cold rolling mills to better control critical processes such as mass flow, differential speed and elongation of products including aluminum foil, plate and sheetAluminium Cold Rolling Mill Process Control NDC4Hi nonreversing cold rolling mill has fourroll irreversible cold rolling mill type of stand It is highly designed to roll the casted and/or hot rolled aluminum coil Aluminum Cold Rolling Mill Dalian Highland Metals Co,Ltd

Aluminum Rolling Mills HARBOR Aluminum

Shaping an aluminum sheet begins with the same process as an aluminum plate Aluminum plates pass through a continuous rolling mill to further reduce plate thickness The final step for the aluminum sheet is cold rolling, where aluminum sheets are compressed between two rollers, reducing material thickness up to 50% Cold rolling eliminates Aluminum Cold Rolling Mill We offer Aluminum Cold Rolling Mill that is used for feeding hot rolled aluminum strip after being cooled to room temperature, there it is steadily passed numerous times between series of rollers until it reaches desired measurement and formed into a coil Click here for more info >> Rolls For Rolling Millrolling mill for aluminum, Aluminum Hot Rolling Mill The rolling mill at Ashland Aluminum is impressive, simply due to its sheer size and extreme rolling strength We take delivery of heavy gauge aluminum coil and roll the coil to the tolerances and mechanical properties our customer requires As you roll the aluminum thinner and thinner you begin to harden the aluminum and make it brittleWhat Is Cold Rolled Aluminum Ashland Aluminum

Vulcan Aluminum Mill Aluminum Coils and Aluminum Sheets

Constructed in 1986, Vulcan Aluminum Mill, a division of Vulcan, Inc, produces aluminum coil and sheet from which a variety of products are manufactured This aluminum rolling mill was the first to use a Hazelett TwinBelt Caster in the SoutheastSMS group offers various cold roll mill technologies for copper, steel and aluminum like tandem cold mill, 18 HS mill, reversing mill, skin pass mill, single stand cold millCold rolling SMS groupThe 90,000poundcapacity holding furnaces provide a continuous flow of alloyed molten aluminum to the roll sheet casters at a rate of 4,000 to 12,000 pounds per hour After cooling, the aluminum coil is delivered to the singlestand, fourhigh cold rolling mill by Reynolds Metals Aluminum Sheet Casting and Rolling Mill

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCOct 08, 2019 The function of the aluminum rolling mill is to roll the original aluminum into a Castrolled alloy strip suitable for cold rolling The molten aluminum must be supplied continuously The melt of aluminum alloy must be clean and have the same Aluminum Rolling Mill Process Cold Rolling Hani TechShaping an aluminum sheet begins with the same process as an aluminum plate Aluminum plates pass through a continuous rolling mill to further reduce plate thickness The final step for the aluminum sheet is cold rolling, where aluminum sheets are compressed between two rollers, reducing material thickness up to 50% Cold rolling eliminates Aluminum Rolling Mills HARBOR Aluminum

Reynolds Metals Aluminum Sheet Casting and Rolling Mill

The 90,000poundcapacity holding furnaces provide a continuous flow of alloyed molten aluminum to the roll sheet casters at a rate of 4,000 to 12,000 pounds per hour After cooling, the aluminum coil is delivered to the singlestand, fourhigh cold rolling mill by Logan Aluminum Rolling Mill To meet the beverage industry's growing demand for light gauge, tighttolerance aluminum sheet stock, Logan Aluminum committed to a major capital expansion project A critical requirement during the project execution was the continual operation of the existing mill without production disruptionLogan Aluminum Rolling Mill: Fluor EPCM Startup ProjectRolling Mill Fume Exhaust Aluminum hot and cold rolling mills can produce significant levels of oil mist/liquid particulate, visible emissions, and/or volatile organic compound (VOC) emissions Emissions occur as a result of coolant evaporation in the mill, and will vary by coolant type and quantity used Mills may be required to reduce Rolling Mill Fume Exhaust APC Technologies, Inc

A BASIC UNDERSTANDING OF THE MECHANICS OF

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCThe majority of cold and foil rolling operations use oilbased lubricants, although some mill systems can accommodate waterbased alternatives The base oil represents more than 90% of the total lubricant volume and acts as a solvent for the load bearing additives and a rollcooling mediumAluminium Rolling Lubrication: part 2 Innoval TechnologyOman Aluminium Rolling Company LLC (OARC) was established in 2011 as a green field aluminium rolling mill plant at the Sohar Industrial Estate to produce flat rolled aluminium products OARC plant is one of the largest added value projects in the Aluminium processing industry at the Sohar Industrial Area, with a total cost of 385 million USDOARC Oman Aluminium Rolling Company LLC

A Review on Chatter Analysis in Cold Rolling process

corporation production mill The computer simulation have been used to study chatters and showed the variation of natural frequency with variety of factors viz friction, rolling speed, tension, reduction and strip width The stability criterion for rolling mill was derived analytically using the factors causing negative and positive damping [8]Quaker Chemical is dedicated to engineering the best cold rolling oils for your specific rolling process From natural to synthetic lubricationAluminum Steel Cold Rolling Metal Lubricants Quaker hengzhong heavy main products include aluminum cast rolling mill,cold rolling mill,aluminum foil rolling machine,tension leveling line,cut to length line,aluminum rolling machine,slitter,cast roll,roller sleeve,casting mill roll shell,aluminum sheet,aluminum coil,aluminum casting mill,aluminum plate,aluminum circle,aluminum casting rolling machine,Color Aluminum Reflective sheet in aluminum cast rolling mill,cold rolling mill,aluminum foil

Difference between Cold Rolled Aluminum and Hot Rolled

The difference between cold rolled aluminum plate and hot rolled aluminum sheet is mainly due to the difference in production process: Cold rolled aluminum is processed by a casting machine into a cast roll and processed by a cold rolling mill;A wide variety of new and used aluminum rolling mills and other equipment including aluminum foil rolling mill, cold rolling mill, continuous casting mill and hot rolling mill, degassing box, grinding machine,multi plate filter for rolling mill oil cleaning, work rollers, plate leveling machine, extrusion plant,high precision cutting saw and others are available with complete technical New and used Aluminum Machinery and EquipmentAluminum Cold Rolling Mill (CRM) With the high speed development of modern economy and expansion of international market, the demand for strip and foil increases greatly It is the guarantee to produce the good quality product to choose the cold rolling mill withAluminum Cold Rolling Mill uemco

Cold rolling mills for aluminum ANDRITZ

Cold rolling mills for aluminum Exact knowledge of the plant and process technology as well as many years of experience enable us to provide highly developed solutions that secure a leading ranking for our products on the world market in terms of quality and productivityLaserSpeed Pro delivers a measurement accuracy of better than +/003% with +/002% repeatability, enabling cold rolling mills to better control critical processes such as mass flow, differential speed and elongation of products including aluminum foil, plate and sheetAluminium Cold Rolling Mill Process Control NDCAA3xxx and AA5xxxseries aluminum grades are typically used for manufacturing beverage cans This is where tandem cold mills (TCM) offer you the most efficient solution Operating several singlestand mills doesn't make economic sense, especially if you want a production volume of up to 400,000 tpyTandem cold mills (Aluminum) SMS group

Aluminum Rolling Mill Process Cold Rolling Hani Tech

Oct 08, 2019 The function of the aluminum rolling mill is to roll the original aluminum into a Castrolled alloy strip suitable for cold rolling The molten aluminum must be supplied continuously The melt of aluminum alloy must be clean and have the same chemical composition, and the liquid level and temperature must be constantJun 23, 2017 The completion of the cold rolling mill is part of the AMAG 2020 project, which began in November 2014 following the commissioning a new hot rolling mill As part of AMAG 2020, the company is investing over EUR 300 million to increase capacity of aluminum strips and sheetsAMAG Opens StateoftheArt Aluminum Cold Rolling Mill ALUMINUM COLD ROLLING MILL — A SINGLE HIGHPRECISION MILL FOR BOTH BREAKDOWN AND FINISHING Primetals Technologies' aluminum cold rolling mills offer a blend of innovative design and proven technology for both new and revamp projects This enables strip to be produced at very tight tolerances and productivity levels resulting in maximum yieldCUTTINGEDGE NON FERROUS ROLLING SOLUTIONS

Reynolds Metals Aluminum Sheet Casting and Rolling Mill

The 90,000poundcapacity holding furnaces provide a continuous flow of alloyed molten aluminum to the roll sheet casters at a rate of 4,000 to 12,000 pounds per hour After cooling, the aluminum coil is delivered to the singlestand, fourhigh cold rolling mill by Types of cold mill: a) Reversing, b) Nonreversing c) Tandem strip rolling mill [3] Choosing the correct type of cold mill depends on the exact range of products that is desired to be produced Cold mills are classified into few categories according to their thickness ranges and speeds To determine theAluminum Sheet Production: General Principles of Cold on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCA BASIC UNDERSTANDING OF THE MECHANICS OF

OARC Oman Aluminium Rolling Company LLC

Oman Aluminium Rolling Company LLC (OARC) was established in 2011 as a green field aluminium rolling mill plant at the Sohar Industrial Estate to produce flat rolled aluminium products OARC plant is one of the largest added value projects in the Aluminium processing industry at the Sohar Industrial Area, with a total cost of 385 million USDZhengzhou Hengzhong Heavy Machinery Manufacturing Co, Ltd is an aluminum platecoil cast rolling machine manufacturer since 1995, which integrates design, Cold rolling mill and annealing furnace YouTubeAluminum Rolling Coolants Hot rolling emulsion Naphthenic or paraffinic mineral oils Emulsifiers (metal and amine soaps and/or nonionic surfactants) Load‐bearing additives (fatty acid, alcohol, ester) Other additives (anti‐oxidant, anti‐corrosion, biocide,) Water Cold rolling oilRoll in Hot and Cold Rolling Mills STLE

Aluminum Cold Rolling Mill Coil Forming Machine Hongye

The max allowable coil weight is up to 25 tons Our cold mill operates at a max speed of 1000m/min AGC/AFC system is available for option The finished aluminum foil processed by our cold rolling mill is up to 008m thick For higher requirements, the thickness could be 0006mm Cold Rolling Mill The new Danieli DiamondFlex 6High Cold Rolling Mill (CM4 designation) will be installed in a new, dedicated building at Logan Aluminum, in Logan County, in Western Kentucky, USA The operation of the new mill will further enhance Logan’s capabilities by rolling 29,500 kg [65,000 Ibs] coils with maximum strip width of 2133mm [84”] at speeds Danieli to supply Logan Aluminum with the world’s most