Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

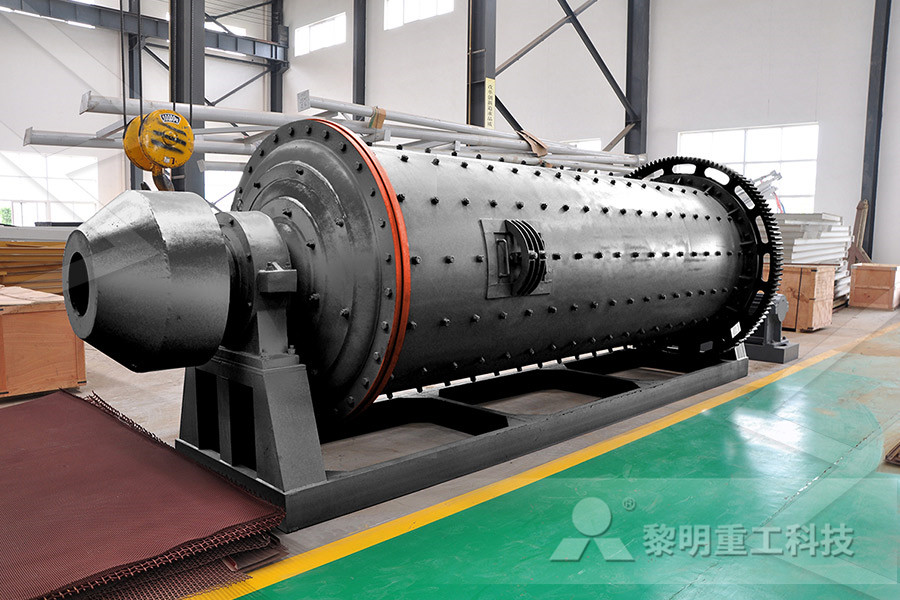

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Capacity Dimensions 2013 Paul O Abbe

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 B Ball Mill Capacity Dimensions 2013ddAug 30, 2019 The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selectingBall Mill Parameter Selection Calculation Power May 30, 2019 Production capacity of ball mill: Date: 13:46 writer:admin Views: There are many factors that affect the production capacity of the ball mill , such as the material nature, the grain size of the grinding material, the required product fineness, the evenness of feeding and the inner loading degree of the millProduction capacity of ball mill:cement production

Ball Mills 911 Metallurgist

The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and the working diameter is only 4’8″ with Oct 15, 2015 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to be Calculate Ball Mill Grinding Capacity 911 MetallurgistBall mills are rated by power rather than capacity Today, the largest ball mill in operation is 853 m diameter and 1341 m long with a corresponding motor power of 22 MW (Toromocho, private communications) View chapter Purchase book Manufacture of Portland CementBall Mills an overview ScienceDirect Topics

3 easy steps to calculate ball mill capacity

Mar 09, 2016 Let us present an easy and convenient service for calculating ball mill capacity Ball mills are one of the most common and popular type of industrial equipment They come in a wide variety of modifications and can be used in mining, oil, drilling, agrochemical, and many other sectors Production of paints, construction materials, dry Ball mills are rated by power rather than capacity Today, the largest ball mill in operation is 853 m diameter and 1341 m long with a corresponding motor power of 22 MW (Toromocho, private communications) View chapter Purchase book Sampling Theory and MethodologyBall Mill an overview ScienceDirect TopicsMill performance is based on mill diameter and length only increases or decreases capacity The Slice Mill is simply a mill of the same diameter as the production mill but much shorter A Slice Mill of 72” diameter by 12” wide would replicate the result of a normal production, mill 72” in diameter as 120” longVariables in Ball Mill Operation Paul O Abbe®

Production capacity of ball mill:cement production

May 30, 2019 Production capacity of ball mill: Date: 13:46 writer:admin Views: There are many factors that affect the production capacity of the ball mill , such as the material nature, the grain size of the grinding material, the required product fineness, the evenness of feeding and the inner loading degree of the millMar 09, 2016 Let us present an easy and convenient service for calculating ball mill capacity Ball mills are one of the most common and popular type of industrial equipment They come in a wide variety of modifications and can be used in mining, oil, drilling, agrochemical, and many other sectors Production of paints, construction materials, dry 3 easy steps to calculate ball mill capacityApr 03, 2021 One of the purposes of the liners is to absorb the impact of the milling movement With the presence of the liners, it decreases the shock, thus causes less or no damage to your ball mill The global Ball Mill Lining market is valued at US$ xx million in 2020 is expected to reach US$ []Global Ball Mill Lining Market Report: Production Capacity

Ball mill Wikipedia

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dryThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsJun 19, 2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculation 911 Metallurgist

how to improve the capacity of ball mill Prominer

Several methods to improve the production capacity of Uniform feeding, and to add shoes right, ball mill can improve production capacity 2The structure of cement ball mill The length diameter ratio of ball mill is associated with production mode, for the open flow production system of grinding machine, in order to ensure the fineness of a qualified product, the length diameter ratio is 35 6Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy Ball Mill and Classifying Production Line ALPA PowderMill performance is based on mill diameter and length only increases or decreases capacity The Slice Mill is simply a mill of the same diameter as the production mill but much shorter A Slice Mill of 72” diameter by 12” wide would replicate the result of a normal production, mill 72” in diameter as 120” longVariables in Ball Mill Operation Paul O Abbe®

production ball mill capacity wentholtexpertisenl

Ball Mill Plant, Wholesale Various High Quality Ball Mill Plant Products from Global Ball Mill Plant Suppliers and Ball Mill Plant Factory,Importer,Exporter at Alibaba ball grinding stone mill grinder capacity 15 tph cement ball mill plant for sale manufacturers of ball mill plant for production of pozzolana cement Get a quoteAug 18, 2019 Supplementing the ball mill media according to changes in ball mill current, grinding sound, output and quality during daily production Generally, a warehouse can be used with 34 grade balls, and fine grinding bins can be 23 gradesFactors That Affect Ball Mill Grinder Capacity And Quality Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock Crusher

Ball Mill, Grinding Mill, Ball Mill Manufacturers, Ball

【 Capacity 】: 200350mm 【Improvement】: Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mill Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and Mar 09, 2016 Let us present an easy and convenient service for calculating ball mill capacity Ball mills are one of the most common and popular type of industrial equipment They come in a wide variety of modifications and can be used in mining, oil, drilling, agrochemical, and many other sectors Production of paints, construction materials, dry 3 easy steps to calculate ball mill capacityBall mills are rated by power rather than capacity Today, the largest ball mill in operation is 853 Thus, it is suitable for pilot and/or industrial scale of MgH 2 production In addition, lowenergy ball mill produces homogeneous and uniform powders when compared with the highenergy ball mill Furthermore, such tumbling mills are Ball Mills an overview ScienceDirect Topics

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightJun 19, 2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculation 911 MetallurgistFeb 24, 2020 Ball mill 1012 is located in line 3 of the mines production circuit and had the potential and capacity to process more material if some modifications were made Collahuasi decided to award the project of repowering this mill to , given the previous positive experience and years the two companies had worked togetherWithin the mining Ball mill upgrade at Collahuasi increases processing

Ball Mill Market Share 2021 Overview Top Key Players

Feb 11, 2021 351 Europe Ball Mill Production Growth Rate (20152020) 352 Europe Ball Mill Production Capacity, Revenue, Price and Gross Margin (20152020) 36 China Ball Mill Production 361 China Ball Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy Ball Mill and Classifying Production Line ALPA PowderBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axisIndustrial Ball Mills: Steel Ball Mills and Lined Ball

CALCULATION OF THE GRINDING BALLS ASSORTMENT FOR THE

Jan 27, 2021 Production capacity: 75±10t/h (Closed circuit, ordinary carbonate cement, specific surface area: ≥320m2/Kg) feeding size≤5mm, moisture≤05%, air speed in mill ≥05m/s Mill rotary speed: 158±01r/min Charging capacity of grinding medium: 230 ton The raw material for cement production has a high abrasion rateNov 30, 2020 The Copper Mountain mill flowsheet is currently a conventional twostage crushing, SAG, pebble crusher, ball milling, and sulphide flotation circuit design The current capacity supports 40,000 t per day of ore processing The 45ktpd Expansion that is currently underway will add a third ball mill in parallel with the two existing ball millsCopper Mountain 65,000 t/d expansion approved including Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall Mill Working Principle And Main Parts

Ball Mill Classifying Production Line ALPA Powder Technology

Capacity matching ALPA’s ball mill classifying production line with reasonable production capacity, large output, stable operation and stable product quality Influencing factors of Ball mill output Feeding particle size and distribution; Scientific calculation of the length to diameter ratio of the mill;