Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

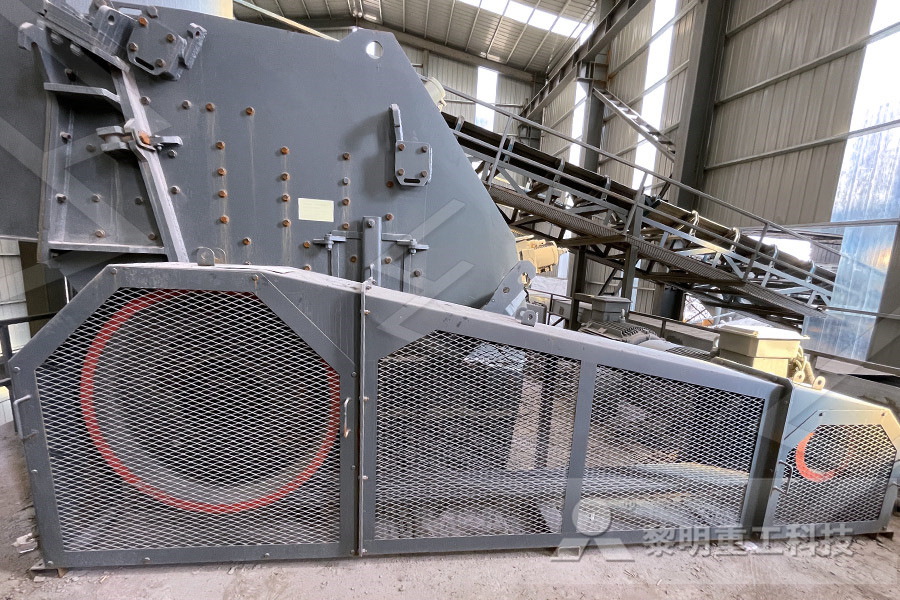

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

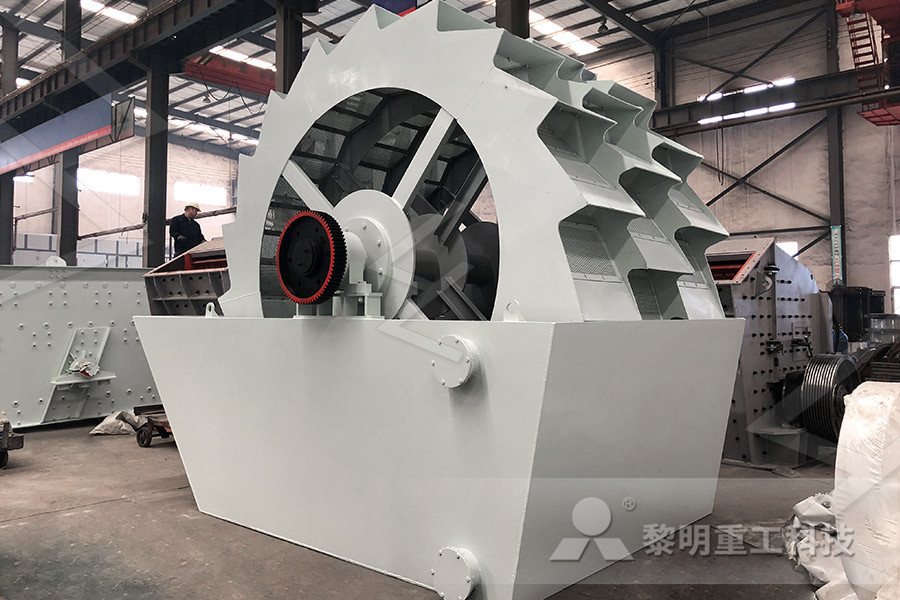

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Development of Masonry Cement from Waste Chalk and

A masonry cement with 4045 % of waste chalk/lime sludge has been developed to satisfy the specific requirements of the Indian Standard Specification 34661999 The mortar prepared from masonry cement and sand retains greater cohesiveness, high water retentivity and workability as compared to mortar prepared from Portland cement and sandprocesses that have developed around the working of chalk and litnestone Separate Step 1 3 reports were produced for each: lime industry (Trueman 2000a) cement industry (T~ueinan 2000b) gypsurn industry (Trueman 2000c) whiting indushy (Trueman 2000d) 2 SCOPE OF THE STEP 4 REPORTLIME, CEMENT AND PLASTER INDUSTRIES STEP 4 REPORTThis industrial legacy is embedded throughout Ebbsfleet’s landscapes The chalk has been extracted over centuries to make lime for cement production creating a dramatic and distinctive landform In 1868 Swans combe was still a predominantly rural community with many acres producing hopsChalk Cement works — Design for Ebbsfleet

Smart solutions for lime, chalk dry mortar FM Bulk

Solutions for extraction and industry We supply systems for the effective transportation and processing of heavy bulk products at sites like chalk quarries and industries such as paper production and the cement industry These include screw conveyors, belt and chain conveyors, bucket elevators and the filling/emptying and processing of big bagsJan 10, 2012 If pozzolana is mixed with lime the result is a binder with hydraulic properties Rocks made of limestone with 25% of baked clay at 1500 °C lead to the production of one of the most popular hydraulic binders, which is called Portland cement Natural chalk is used to prepare rapidly hardening chalk and filling chalkCement and chalk EniscuolaMar 12, 2020 Thurrock supplied chalk to other parts of Essex and Zachariah Button built Belmont Castle on chalk land between 1780 and 1785 In 1824 a Portland Cement patent was taken out, improved by 1850 It had a vital advantage over lime mortar as it dried quickly, was hard and didn’t absorb waterA cement story: Industry that played a huge part in

Lime (material) Wikipedia

Selenitic lime, also known as Scotts' cement after Henry Young Darracott Scott is a cement of grey chalk or similar lime, such as in the Lias Group, with about 5% added gypsum plaster (calcined gypsum) Selenite is a type of gypsum, but selenitic cement may be made using any form of sulfate or sulfuric acidCEMENT INDUSTRY Key environmental issues Cement is a basic material used for building and civil engineering construction The production of cement in the European Union stood at 2675 million tonnes in 2006, equivalent to about 105 % of world production In 2008 there were 268 installations producing cement clinker and finished cement in theCement, Lime and Magnesium Oxide Manufacturing IndustriesJul 01, 1993 Chalk can, however, wholly replace the limestone powder used as a filler fraction in cement concrete tiles both in plain as well as terrazzo typeUtilization of waste chalk from fertilizer industry as

Professional Marking Chalk Keson Industries

Keson marking chalk sticks to your line until you decide you want it to stick to something else Over the years, we’ve fine tuned our formulas to produce chalk that A masonry cement with 4045 % of waste chalk/lime sludge has been developed to satisfy the specific requirements of the Indian Standard Specification 34661999 The mortar prepared from masonry cement and sand retains greater cohesiveness, high water retentivity and workability as compared to mortar prepared from Portland cement and sandDevelopment of Masonry Cement from Waste Chalk and The chalk has been extracted over centuries to make lime for cement production creating a dramatic and distinctive landform In 1868 Swans combe was still a predominantly rural community with many acres producing hops Several oast houses were located in Chalk Cement works — Design for Ebbsfleet

Secondary School with Chalk? Cement Lime Gypsum

Jun 13, 2014 The mineral chalk is excavated in wet condition, ground, mixed in highcapacity slurry vessels and compacted to form a filter cake, and then finally dried in a flash dryer incorporating a hammer mill He also pointed out his company’s other fields of business, outside the cement, lime and gypsum industries, such as port facilities CEMENT INDUSTRY Key environmental issues Cement is a basic material used for building and civil engineering construction The production of cement in the European Union stood at 2675 million tonnes in 2006, equivalent to about 105 % of world production In 2008 there were 268 installations producing cement clinker and finished cement in theCement, Lime and Magnesium Oxide Manufacturing Cement is the second most consumed substance on Earth after water, fulfilling an essential role in providing society’s need for housing and infrastructure while lime is used in a variety of applications including in the iron steel, chemical, paper and pharmaceutical industriesCement Lime Industries Reducing CO2 Emissions by

Limestone and Chalk Uses Compare Nature

Know all about Limestone and Chalk and their uses in industries and architecture in the upcoming sections Commercial uses of Limestone: animal feed filler, as a feed additive for livestock, paper industry, raw material for manufacture of quicklime, slaked lime, soil conditioner, used in aquariums, whiting material in toothpaste, paint and paperFeb 07, 2019 Chalk is soft raw material, it does not require crushing Marl is a limestone with admixtures of silex and clay substances, as well as iron oxideIt is a transitional stage to clay The hardness of marl is lower than the hardness of limestone The more clay substances, the lower its hardness This is an excellent raw material for cement productionRAW MATERIALS IN CEMENT PRODUCTIONWilliam Aspdin, the son of Joseph Aspdin, had emigrated from England to Hamburg in 1857, subsequently setting up, with the help of sponsors, small production facilities for Portland cement in Hamburg and Lüneburg He had also heard of the socalled “white earth” – the chalk deposits of 150 years of Portland cement Cement Lime Gypsum

(PDF) PRODUCTION OF LIME USING LIMESTONE OBTAINED FROM

Other industries that use lime include cement, soap, steel and paper industries (Okonko, 1990) Presently there is no large scale lime production in the country except those committed solely to serve particular industries such as paper or steel (Dolomite Lime) is produced limestone /Chalk The recarbonation process is essentially the Keson marking chalk sticks to your line until you decide you want it to stick to something else Over the years, we’ve fine tuned our formulas to produce chalk that Professional Marking Chalk Keson IndustriesIn many uses, lime reacts more quickly than limestone but is more expensive, because a high temperature is required to produce it from limestone Uses of limestone and lime Figure 1 Principal uses of limestone and lime The principal uses, by far, of limestone and lime are in the construction industry and cement makingCalcium carbonate Essential Chemical Industry

History of lime in mortar Graymont

Natural cement was produced by burning a mixture of limestone and clay together in kilns similar to those used for lime The resulting product was ground and stored in waterproof containers Typically, natural cements had higher clay contents than hydraulic lime CEMENT BULK MATERIAL CREADIS > INDUSTRIES > CEMENT BULK MATERIAL CEMENT, LIME, AGGREGATES AND BULK MATERIAL HANDLING The experience gained over the years in developing specialised process solutions is now paying off in theCEMENT BULK MATERIAL : CREADISJan 02, 2019 Chalk is a very special cement raw material It is not easy to handle this chalk due to its fineness and moisture Tailored solutions are in demand All known processes to make Portland cement clinker from chalk are presented in this article Modern cement production with chalk Cement Lime Gypsum

Development of Masonry Cement from Waste Chalk and

A masonry cement with 4045 % of waste chalk/lime sludge has been developed to satisfy the specific requirements of the Indian Standard Specification 34661999 The mortar prepared from masonry cement and sand retains greater cohesiveness, high water retentivity and workability as compared to mortar prepared from Portland cement and sandMar 31, 2017 The chalk (one of a number of limestone varieties) from the hillside at Beeding had long been recognized as being of a particularly good quality for use as lime and cement and this attracted the attention of those seeking to make profit from the industryCHALK A History of Shoreham (Beeding) Cement Works Lime sludge (chalk) obtained from fertilizer industry has been tried as the constituent of masonry cement, burning of lime sludge to make building lime, as raw material for making flooring tiles and compounding of burnt lime waste with surkhi/fly ash to make lime Utilization of waste lime sludge as building materials

Cement, Lime and Magnesium Oxide Manufacturing

CEMENT INDUSTRY Key environmental issues Cement is a basic material used for building and civil engineering construction The production of cement in the European Union stood at 2675 million tonnes in 2006, equivalent to about 105 % of world production In 2008 there were 268 installations producing cement clinker and finished cement in theWilliam Aspdin, the son of Joseph Aspdin, had emigrated from England to Hamburg in 1857, subsequently setting up, with the help of sponsors, small production facilities for Portland cement in Hamburg and Lüneburg He had also heard of the socalled “white earth” – the chalk deposits of 150 years of Portland cement Cement Lime GypsumJul 01, 1993 CONCLUSIONS Use of the waste chalk powder in bitumen mastic, cement concrete flooring tiles and masonry cement seems to be both economically viable and technically feasible The results of chemical analysis show that the chalk, a by product of fertilizer industry contains enough quantity of calcium carbonate to be utilized in place of dolomite Utilization of waste chalk from fertilizer industry as

Difference Between Limestone and Chalk Compare the

Aug 15, 2018 Ex: The Great Pyramid Moreover, it is the major ingredient in making quicklime, slaked lime, cement, etc Apart from that, we can use this mineral as a soil conditioner to neutralize acidic soils What is Chalk? Chalk is a form of limestone containing calcite as the major mineral; about 99% Therefore, it is also a sedimentary carbonate rockLime is a very important chemical which is of central importance to many industries including several that we will discuss in these pages We will use it initially to produce lye for making soap Later we will use it to make glass Lime is also widely used in agriculture, water treatment, paper manufacture, and in mixing cement and concreteCaveman to Chemist Projects: Lime and LyeThe uses of Limestone in construction industry include Cement manufacture, Cobblestones, For road aggregate, Production of glass and ceramics, Raw material for the manufacture of mortar, Roadstone, Source of calcium and that of Chalk include As dimension stone, Cement manufacture, Construction aggregate, For road aggregate, Making natural Limestone vs Chalk Compare Nature

Portland Lime Mortar N, S, M QUIKRETE: Cement and

QUIKRETE® Portland Lime Mortar (Types S, N, M) is a high strength Commercial Grade dry preblended mixture of sand and cements specially selected for masonry applications Meets the requirements of ASTM C270 types S, N, or MLime is abundant in much of the UK through outcrops of limestone and chalk It was burnt as early as the fourth century BC where it was first used as a building material The British Lime Association (BLA) is committed to broadening the public's knowledge of the benefits of lime as well as representing the interests of the UK lime sector in Limeindustrial Mineral ProductsFind out how to make lime from limestone or chalk in the ground and how a lime kiln transforms these rocks into a valuable product The principal use of Dolomitic lime is in the steel industry In the UK, around 250,000 tonnes per year is used for this purpose The bricks are also used in lime and cement kilns Dolomitic lime is also British Lime Association (BLA) part of the Mineral