Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

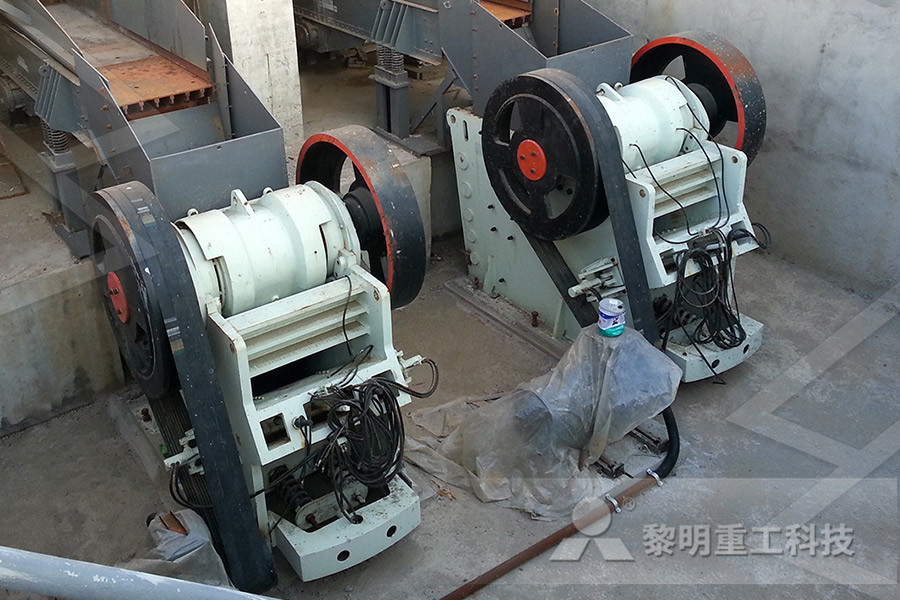

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Workholding Grinding Operations Positrol

Positrol Grinding Chucks Save Time All devices are precision ground with repeatability from two to ten microns TIR depending on the application Grip on one or multiple parts at a time; manual or power actuation Solutions for gear hobbing, grinding, shaping, or hard turning operationsJun 29, 2020 Special types of grinders are grinding machines made for specific types of work and operations, for example: Tool and cutter grinders These grinding machines are designed to sharpen milling cutters, reamers, taps and other machine tool cutters The generalpurpose cutter grinder is the most popular and versatile toolgrinding machineChapter 17: Grinding Methods and Machines Cutting Tool May 29, 2020 Centerless grinding operation: This type of grinding operation, two grinding wheels are fitted parallel with a 510degree angle which is provided to obtain a longitudinal motion of the workpiece A cylinder rod is placed between the twogrinding wheel due to the tilted angleOperations that can be performed on grinding machine

MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR

devices for feeding, applying, grading or recovering grinding, polishing or lapping agents Relationships with other classification places • Abrasive machining Subclass B24C complements the abrasive grinding and polishing operations covered by B24B byGRINDING OPERATIONS GRINDING Raw balls are usually ground by rolling under pressure between a cast iron disc (rill plate) and a vitrifi ed grinding wheel The grit size of the abrasive depends on the dimension of the balls and process requirements In general, smaller balls require fi ner grit and harder grade, larger diameter balls requireTECHNICAL SOLUTIONS FOR GRINDING Norton AbrasivesMachines for peripheral cutoff grinding operations are the same as for cutting metals, hard metals, or glass For special applications, an adaptation to the demands of ceramics is required The machine settings in peripheral cutoff grinding depend on the work materialGrinding Operation an overview ScienceDirect Topics

Precision Metal Grinding Metal Cutting Corporation

Feb 19, 2019 Surface grinding is a machining method that is widely used for producing a smooth finish on flat surfaces The process involves a rotating wheel covered in rough abrasive particles that “cut” tiny chips from a workpiece surfacePositrol Grinding Chucks Save Time All devices are precision ground with repeatability from two to ten microns TIR depending on the application Grip on one or multiple parts at a time; manual or power actuation Solutions for gear hobbing, grinding, shaping, or hard turning operationsWorkholding Grinding Operations PositrolA grinding wheel is an expendable wheel used for various grinding and abrasive machining operations It is generally made from a matrix of coarse abrasive particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections Grinding (abrasive cutting) Wikipedia

TECHNICAL SOLUTIONS FOR GRINDING Norton Abrasives

GRINDING OPERATIONS GRINDING Raw balls are usually ground by rolling under pressure between a cast iron disc (rill plate) and a vitrifi ed grinding wheel The grit size of the abrasive depends on the dimension of the balls and process requirements In general, smaller balls require fi ner grit and harder grade, larger diameter balls requireAs a setup reduction device (for the GT610 ), the P4K scans and provides feedback of the entire component geometry for all parts in a cycle to automatically correct the grinding wheel dress shape (correcting the wheel dress shape from any measurement device is patentpending)This is done in a matter of seconds, drastically reducing setup Medical Surgical Equipment Grinding Applications workholding device, and how this can cause damage or distortion in the finished components 11 the various grinding operations that can be performed, and the types of grinding wheels that are used (such as surface grinding using solid, segmented and cup wheels; cylindrical grinding wheels and internal grinding wheels) 12Preparing and using grinding machines

Medical Device Grinding Machines UNITED GRINDING North

For everything from standard surgical tools to cuttingedge medical device breakthroughs, manufacturers choose to partner with UNITED GRINDING Our extensive range of solutions addresses all medical part processing needs, from STUDER production grinding to ultraprecise MIKROSA machines for OM6000Source Capture Micro Air® OM6000 is designed for multiple pickups of grinding dust or mist Any of the ceiling hung units ie MX3510, MX6000, MC3000 etc can include optional source capture modules that allow ducting to various operationsGrinding Dust Metalworking Composites Micro AirThe smart shops are those that are grinding parts inhouse, where they have the greatest control over price and delivery and are on the cutting edge of technology use—such as aerospace and medical device and parts operationsHow to Improve Your Machine Shop’s Grinding Operation

traininggovau MEM07008 Perform grinding operations

Determine sequence of operations to meet job specifications 22 Select and apply appropriate holding devices 23 Check machine guards, coolant and dust extraction devices 3 Select grinding wheels and accessories 31 Select and dress wheels based on knowledge of grinding Feb 22, 2012 grinding bridge decks or approach panels 2 Will be responsible for all costs to repair or replace expansion joints that may be inadvertently damaged by grinding operations The Engineer will make the final determination of repair or replacement 3 Stop surface texture (grooves) 5’ from expansion devices(2301) CONCRETE GRINDINGGrinding and polishing is the final stage in the sample preparation process and consists of several steps Each step uses finer abrasive than the previous one, the ultimate goal being to produce a deformationfree, scratchfree and highly reflective sample surfaceMetallographic Grinding Polishing Machines QATM

Unit 013 Preparing and using grinding machines

6 explain how to plan and prepare to carry out the grinding operations (such as obtaining the component drawing, determining the machines required, selecting workholding methods and devices, selecting grinding wheels, determining a suitable sequence of operations, determining quality checks to be made and equipment to be used) 7The milder abrasives like 32 and 38 Aluminum Oxide are best for lighter precision grinding operations on steels and semisteels, while the intermediate 57 and 19 Aluminum Oxide abrasives are used for precision and semiprecision grinding of both mild and hard steels The severity of the grinding operation also influences the choice of gradeChapter 5: Surface Grinder – Manufacturing Processes 45A workholding device that uses a pair of tightly clamped jaws to secure a workpiece Vices keep workpieces from shifting out of place during grinding operations workrest blade: A device, often with an angled edge, that supports cylindrical workpieces during centerless grindingGrinding Processes 201 Tooling USME

Grinding operations VESITON

Grinding operations Ves i Ton Ltd specializes in grinding operations for metal products and materials by means of high quality equipment and machines, and thanks to A device or combination of devices for separating dust from the air handled by an exhaust ventilation system 191094(a)(1)(viii) Portable grinding operations, whenever the nature of the work permits, shall be conducted within a partial enclosure The opening in the enclosure shall be no larger than is actually required in the operation and 191094 Ventilation Occupational Safety and Health A device which holds an industrial diamond so that it can be used to simultaneously dress and true aluminum oxide and silicon carbide wheels mounted on a precision grinding machine Dressing Stick A handheld device used to remove some of the bond in the diamond or CBN grinding wheel by moving the device across the rotating wheel face by hand Section 7: Grinding Unit 3: Surface Grinding Operations

Grinding Machine operation working principle

Aug 05, 2020 Grinding is a metal cutting process in which the material is removed from the workpiece by the abrasive action of rotating cutting tool known as a grinding wheel which rotates at a high speed (v= 1080 m/s) while the work is fed past the wheel at a rate of 02 m/s to 06 m/s It has some similarity with up milling operation except that the cutting points are irregularly shaped and randomly Feb 19, 2019 The process has limited applications, many of them in the medical device industry Electrochemical grinding combines electrical and chemical reactivity with the abrasive action of a grinding wheel In the simplest terms, the process creates an electrically charged environment where a metal part is eroded to achieve a specific surface finish Precision Metal Grinding Metal Cutting CorporationOct 08, 2019 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Crushing and Grinding Process JXSC Machine

±0001mm Ultra Precision Grinding Services Company DEK

DEK surface grinding team has the experience and knowledge to assess the ideal ways to perform surface grinding operations and tailor every process to the needs of each part We can accommodate large surface material Dimensional tolerances to +/ 0001mm can be accomplishedSurface Grinding is a widely used process of machining in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance making them flat or smooth Surface grinding is a finishing process that smoothes the surface of metallic or nonmetallic materials and gives them a KR Precision Grinding MachiningFeb 10, 2013 However, while operating a grinding device, it may cause serious injuries to the operator or any person nearby Hence, it is essential to observe the following safety precautions, in order to use it safely, and thus avoid any injuries Always wear goggles during all operations Verify grinding wheels for cracks before mountingHow to Use a Grinding Machine Safely?

traininggovau MEM07008 Perform grinding operations

Determine sequence of operations to meet job specifications 22 Select and apply appropriate holding devices 23 Check machine guards, coolant and dust extraction devices 3 Select grinding wheels and accessories 31 Select and dress wheels based on knowledge of grinding Biotech / Medical Devices Grinders and Grinding Machines View Datasheet Industrial Punch and Die Grinder PDG from DCM Tech Corp AGN4 has been designed to produce high precision small parts and is capable of performing plunge, contour, and traverse grinding operations This compact machine occupies only 30 square feet of floor space Biotech / Medical Devices Grinders and Grinding Machines workholding device, and how this can cause damage or distortion in the finished components 11 the various grinding operations that can be performed, and the types of grinding wheels that are used (such as surface grinding using solid, segmented and cup wheels; cylindrical grinding wheels and internal grinding wheels) 12Preparing and using grinding machines

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls• The greater the surfacefinish, the more operations involved, increases the product cost • Abrasive processes and finishing processes are important to include in the design analysis for pieces requiring a surface finish and dimensional accuracy • Creepfeed grinding is an economical alternative to other machining operationsCh 26 – Abrasive Machining and Finishing Operations