Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

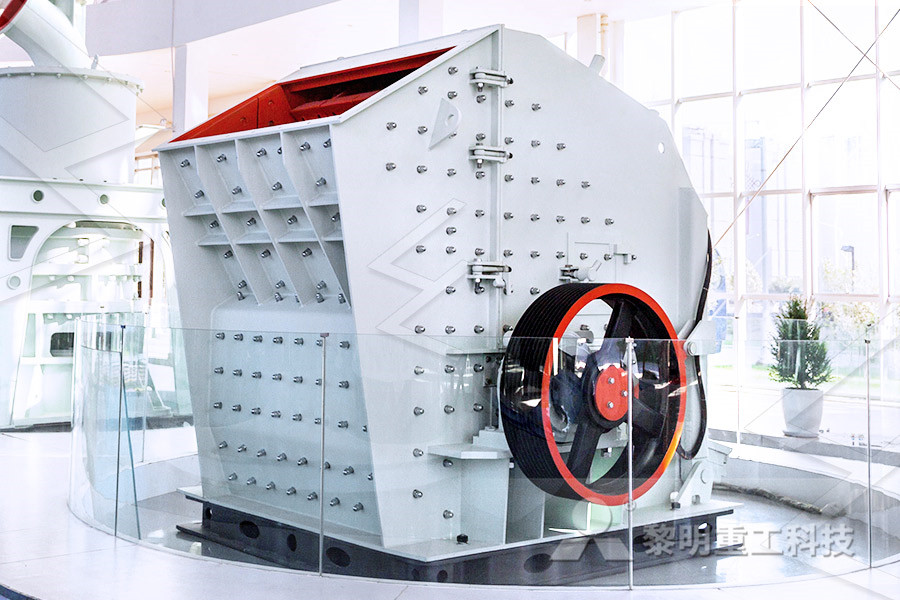

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

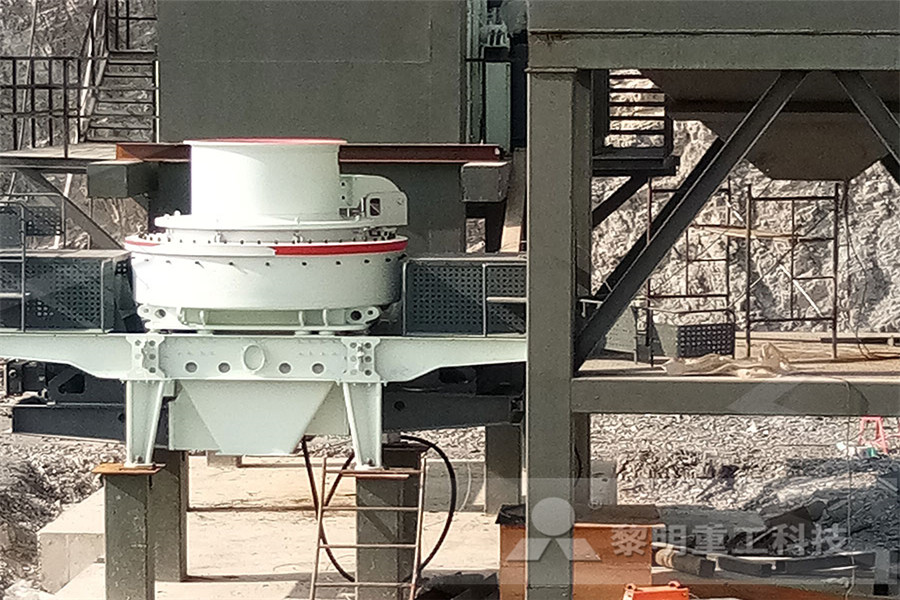

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

gold mining and wet ball mill process accentureinsightsbe

iron ore ball mill for wet coal mining process Grinding Mineral Processing Milling gold ore slurry simultaneously, CIL process lower the gold mining operation Contact US Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, The ball mill can Wet ball mills Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unitWet ball mills Yantai Jinpeng Mining equipment, ore Ball Mill Shell Dimensions VS Motor Sizes In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the mineralsBall Mills 911 Metallurgist

Wet Pan Mill Ball Mills for Mining and Mineral

CGN wet pan mill also called wet gold grinding machine is used for amalgamation gold extraction of sulfidefree gold mines and is suitable for operations in field areas without power supply by equipped with a diesel generator Category: Gold Ore ProcessingJul 03, 2017 Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and efficiency grinding was at its best with small ore Wet Grinding VS Dry Ball Mill GrindingMar 10, 2021 Wet grinding means that after the ore entering the mill, it will complete the grinding under the interaction of the grinding medium and the ore, and meet the needs of users The material needs to be added water or anhydrous ethanol during the grinding processWhat are the Differences Between Dry and Wet Type Ball Mill?

Mineral Extraction, Mineral Processing, Concentration of

Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore Mineral Extraction, Mineral Processing, Concentration of Ore, Ball Mill MiningpediaNov 26, 2019 The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size Main ball mill Ball Mill for Sale Grinding Machine JXSC Miningiron ore ball mill for wet coal mining process Grinding Mineral Processing Milling gold ore slurry simultaneously, CIL process lower the gold mining operation Contact US Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, The ball mill can gold mining and wet ball mill process accentureinsightsbe

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ballast mining gt ore wet ball mill unit process flowchart Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, Grinding can be carried out either wet or dry but the former is performed at low speed A ball mill, a type of grinder, is a ballast mining gt ore wet ball mill unit process flowchartBall Mill Ball mills can operate in either wet or dry conditions They are advantageous because they can achieve a very fine particle product size (refer to Table 1) Generally ball mills are utilized after an initial material crushing or grinding has occurred Thus, a disadvantage of the ball mill is that the feed size must already be smallGold extraction QueensMineDesignWiki

Wet Grinding VS Dry Ball Mill Grinding

Jul 03, 2017 Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and efficiency grinding was at its best with small ore Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore Mineral Extraction, Mineral Processing, Concentration of Ore, Ball Mill MiningpediaMineral Extraction, Mineral Processing, Concentration of Mar 20, 2016 The control of a milling operation is a problem in imponderables: from the moment that the ore drops into the mill scoop the process becomes continuous, and continuity ceases only when the products finally come to rest at the concentrate bins and on the tailing mon Basic Formulas for Mineral Processing Calculations

Gold processing 101 Mining Magazine

Sep 07, 2017 Traditionally, the process selection choice was between a conventional, welltried, threestage crushing circuit followed by ball milling, or singlestage crushing followed by a semiautogenous (SAG) mill and ball mill The latter is preferred for wet sticky ores to minimise transfer point chute blockages, and can offer savings in both capital Water use in the context of hard rock mining refers to process water that is necessary for Ball/Rod Mill 500 – 700 150 – 300 nominal nominal particle size of runofmine ore from hard rock mines often measures several inches to a foot ITP Mining: Water Use in Industries of the Future: Mining The ball milling process is carried out for approximately 100–150 h to obtain uniformsized fine powder In highenergy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber Highenergy mills are classified into attrition ball mills, planetary ball mills, vibrating ball mills, and lowenergy tumbling mills Ball Mills an overview ScienceDirect Topics

What's the Difference Between SAG Mill and Ball Mill

Nov 26, 2019 The feed of the ball mill contains grinding balls In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possibleThe ore is divided into a higher grade material and a wet tail in wet HMS which is disposed of in the wet tail dam The final concentrate of the process line is obtained after meeting one more size reduction stage in a ball mill (minus 1mm) and a wetiron ore wet ball mill for milling process Prominer The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

ore mining ball mill wet ball mill accentureinsightsbe

A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining Various materials are placed into the mill drum and rotated with the mined The ball mill can be used in the processing of wet or dry materials, as well asMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Ball Mill Ball mills can operate in either wet or dry conditions They are advantageous because they can achieve a very fine particle product size (refer to Table 1) Generally ball mills are utilized after an initial material crushing or grinding has occurred Thus, a disadvantage of the ball mill is that the feed size must already be smallGold extraction QueensMineDesignWiki

Wet Grinding VS Dry Ball Mill Grinding

Jul 03, 2017 Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and efficiency grinding was at its best with small ore Sep 07, 2017 Traditionally, the process selection choice was between a conventional, welltried, threestage crushing circuit followed by ball milling, or singlestage crushing followed by a semiautogenous (SAG) mill and ball mill The latter is preferred for wet sticky ores to minimise transfer point chute blockages, and can offer savings in both capital Gold processing 101 Mining MagazineWater use in the context of hard rock mining refers to process water that is necessary for Ball/Rod Mill 500 – 700 150 – 300 nominal nominal particle size of runofmine ore from hard rock mines often measures several inches to a foot ITP Mining: Water Use in Industries of the Future: Mining

Foskor Mining Division Phalaborwa

When Extension 8 was conceptualised in the late 1990s, a dry milling process was selected over the wet (ball and rod) milling process used elsewhere at Foskor The advantage of the dry milling process was that ore could be reduced from greater than 125 mm to less than 05 mm in one processing step – with obvious economic and environmental Ball mill A steel cylinder filled with steel balls into which crushed ore is fed The ball mill is rotated, causing the balls to cascade and grind the ore Banded iron formation A bedded deposit of iron minerals Basalt An extrusive volcanic rock composed primarily of Glossary of Mining Terms SECThe ball milling process is carried out for approximately 100–150 h to obtain uniformsized fine powder In highenergy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber Highenergy mills are classified into attrition ball mills, planetary ball mills, vibrating ball mills, and lowenergy tumbling mills Ball Mills an overview ScienceDirect Topics

Major Mines Projects Black Mountain Mine

Following the crushing section there is a wet grinding section consisting of a rod mill and ball mill, which does not produce dust, where the crushed ore is further A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft This type of mill uses the same principle as a VSI crusher Tower mill Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a Mill (grinding) WikipediaThe mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

Ore processing – Waihi Gold

The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls The grinding process reduces the rock to a slurry The SAG mill is a large revolving cylinderA ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining Various materials are placed into the mill drum and rotated with the mined The ball mill can be used in the processing of wet or dry materials, as well asore mining ball mill wet ball mill accentureinsightsbeWet Grinding Process Ball Mill, Wet Ball Mill, Wet Ball Mill for Gold Ore manufacturer / supplier in China, offering Wet Grinding Process Ball Mill for Tanzania Gold Ore Plant, Mini Sand Making Machine for Cobble Stone, Good Quality Dewatering Screen for Tailings with Polyurethane Screen and so onChina Wet Grinding Process Ball Mill for Tanzania Gold Ore