Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

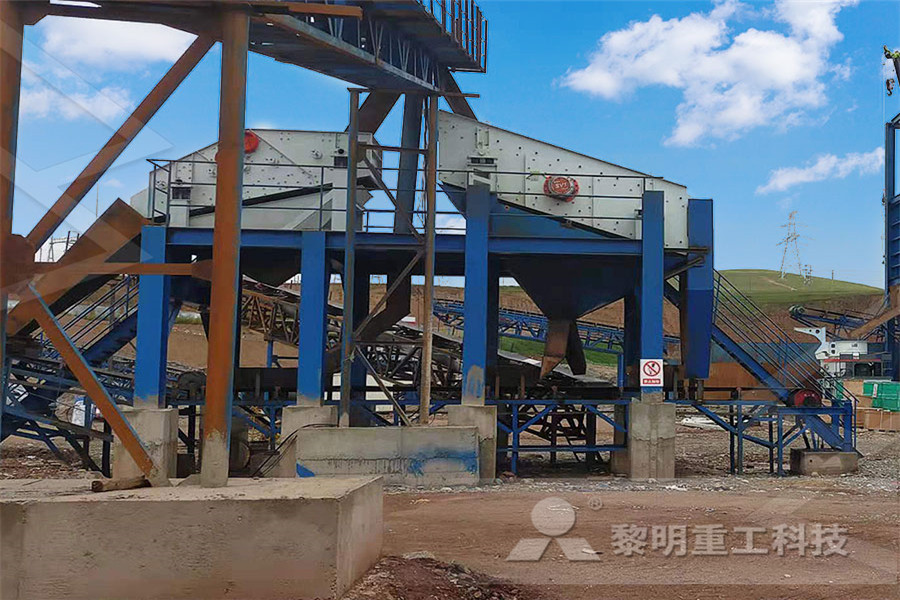

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Dry dense medium separation of iron ore using a gas–solid

Sep 01, 2010 The dry dense medium separation of iron ore based on floating and sinking of ore particles in a gas–solid fluidized bed was investigated using zircon sand as the fluidized medium The floatsink of ore particles with mean size Dave = 236 mm was investigated as the fluidizing air velocity and the floatsink time were variedThe dry dense medium separation of iron ore based on floating and sinking of ore particles in a gas–solid fluidized bed was investigated using zircon sand as the fluidized medium The floatsink of ore particles with mean size D ave = 236 mm was investigated as the fluidizing air velocity and the floatsink time were variedDry dense medium separation of iron ore using a gas–solid Dense medium separation (DMS) is a robust process that can be conducted at particle sizes as coarse as 300 mm and as fine as 500 µm with high separation efficiency, depending on liberation characteristics of the value minerals The DMS process involves three steps: feed preparation, dense medium separation, and ferrousbased media recoveryDense Medium Separation An Effective and Robust Pre

Dense Media Separation (DMS) SGS

In certain circumstances, dense media separation plants can be configured to follow complex gravity circuits, multi gravity separation and/or other separation techniques such as flotation This can provide effective low cost solutions to allow the optimal economic recovery of complex oresThe mine’s currently beneficiates Agrade and Bgrade ore (haematite containing >58% iron) by means of Dense Media Separation (DMS) All other material originating from the run of mine is placed on site as residue dumps or stockpiles due to the absence of a suitable beneficiation process available to process the lowgrade oreUPGRADING OF THE EXISTING DENSE MEDIA SEPARATION May 22, 2016 The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over the range of specific gravities from 125 to 340 can be maintained within close limits and is cleaned and recovered by magnetic meansHeavy Media Separation Process 911 Metallurgist

Dense Media Separation – a Valuable Process for

Jun 15, 2018 The “Condor” Dense Media Separator is a dynamic cylindrical separator In the DMS unit, the dense media is pumped from the lower end of the cylinder (medium inlet 1 and 2) as shown in Figure 1 Utilising gravitational and centrifugal forces, a tangential or involute inlet forces the media to spiral alongside the wall, creating a vortex Densemedia separation (DMS) processes have shown promise as a preconcentration stage and has been incorporated into platinumgroup metals flowsheets, to separate barren waste rock from ore prior to milling The beneficiation of chromite and iron ore using gravity and magnetic separationPhysical Separation MINTEKThe mining blocks have potential to produce varying product grades with different recoveries Ore characterisation was conducted on the GR80 mining block, lowgrade stockpiles (ie C grade ore reserves Jig discard and dense medium separation (DMS) runofmine (ROM) materialOptimization of Dense Medium Cyclone Plant for the

RECENT DEVELOPMENTS IN PRECONCENTRATION USING

While dense media separation is used extensively in the coal industry and somewhat commonly in the diamond industry, its use has not been extensively exploited for other mineral systems The response of upgrading low grade sulfide based nickel ores using dense media cyclones has been reported on Sep 01, 2010 The ore particles of +6 − 100 mm in size are treated by the wet dense medium separation , for which the density of the dense liquid is adjusted at 2750–3150 kg/m 3 Although development of dry separations for iron ore is strongly needed, the dry dense medium separation has not been tested for iron oreDry dense medium separation of iron ore using a gas–solid Jul 03, 2019 Dense media separation also referred to as heavy media separation Application of dense media separation plant The DMS can be used in the jewelry industry, because of the diamond body denser than rock, and may also be used in the iron ore industry, since hematite more dense Dense Media Separation DMS HMS JXSC Machine

Dense Medium Cyclone Dense Media Separation Multotec

Proven to improve efficiency across the world’s toughest iron ore, platinum, diamonds and coal separation applications, Multotec manufactures a complete range of dense medium cyclones for your application or other dense media separation equipment, for your applicationThe Sishen Iron Ore Company (Pty) Ltd (SIOC) is investigating the feasibility of upgrading the existing DMS Plant at Sishen Mine to UHDMS to allow for the processing of low grade iron ore material to produce a saleable iron ore product UltraHigh Dense Media Separation (UHDMS) is a technology that will allow for the processing ofUPGRADING OF THE EXISTING DENSE MEDIA SEPARATION In certain circumstances, dense media separation plants can be configured to follow complex gravity circuits, multi gravity separation and/or other separation techniques such as flotation This can provide effective low cost solutions to allow the optimal economic recovery of complex oresDense Media Separation (DMS) SGS

DenseHeavy Medium Separation HMS / DMS Process

Jun 23, 2015 HMS and DMS are acronyms for Heavy (Dense) Medium Separation and is applied to the process of preconcentration of minerals – mainly the production of a high weight, low assay product, which may be rejected as waste In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals of different specific gravityJun 15, 2018 The “Condor” Dense Media Separator is a dynamic cylindrical separator In the DMS unit, the dense media is pumped from the lower end of the cylinder (medium inlet 1 and 2) as shown in Figure 1 Utilising gravitational and centrifugal forces, a tangential or involute inlet forces the media to spiral alongside the wall, creating a vortex Dense Media Separation – a Valuable Process for Dense Media Separation is a wellknown sinkfloat method and technology used within the coal, iron ore and diamond industries In the process of Dense Media Separation in diamonds, a powdered ferrosilicon (which is an alloy of iron) is suspended in water to form a very defined pulp density (heavy liquid), close to the density of diamond (352 g Dense Media Separation of Diamonds – DMS Powders

Ferrosilicon Frequently Asked Questions DMS Powders

Dense Media Separation is a sinkfloat method used within the coal, iron ore and especially diamond industries The powdered ferrosilicon is suspended in water to form a very specific pulp density (heavy liquid), close to the density of diamonds (352 g/cm3)Title: Dense Media Separation (DMS) Subject: SGS offers full capabilities in dense media separation for the recovery of diamonds Our DMS plant facilities are fully secured in locked compounds and comply with all applicable health, safety and environmental regulationsDense Media Separation (DMS) sgsJun 10, 2013 The dense medium sand compositions investigated were iron power with between 30 and 60% zircon (A) to investigate separation points in the 29–37 g/cm 3 density range and silica powder with between 80 and 100% zircon (B) to investigate separation points in the 22–255 g/cm 3 density range In a typical test, five spheres were randomly Copper ore density separations by float/sink in a dry sand

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 Feed for the dense media separation must be hard and compact with non porous gangue material Heavy media cyclone – The process is used for iron ore fines with size range of 02mm to 6 mm The cyclone type separator utilizes centrifugal as well as gravitational forces to make separation between ore and gangue materialDense medium separation (DMS) is one of several preconcentration methods used for early waste rejection from runofmine ores at relatively coarse particle sizes prior to additional milling and beneficiation DMS has been used extensively in the coal, diamonds, mineral sands, base metals and iron ore industries to produce either a final product or as a preconcentration stepDense media separation a valuable process for Mar 03, 2021 Magnetite is used in dense media separation in the potash extraction to remove NaCl from solution, leaving the valuable KCl behind Potash mining Electrical industry Along with hematite, Magnetite is one of the essential iron ore At 72 %, iron has the highest content of this metal The term iron oxide black means finely ground Magnetitedense media separation Archives Mount Polley

heavy medium separation process iron ore

Processing Iron Ore157 Мб DenseMedia Separation (DMS) Widely used and also proven in the diamond and coal industries, Tenova Mining Minerals’ DMS plants are highly effective for iron ore processing and can treat iron ore at ultra high separation densitiesProven to improve efficiency across the world’s toughest iron ore, platinum, diamonds and coal separation applications, Multotec manufactures a complete range of dense medium cyclones for your application or other dense media separation equipment, for your applicationDense Medium Cyclone Dense Media Separation MultotecA considerable debate has arisen regarding the best route for the beneficiation of iron ore Supporters of jigging technology claim that although the technology is old, due to recent advances in jig control and a better understanding of the separation processes within jigs, it offers significant advantages over dense medium separation, especially in terms of reduced capital and operating costs Jigging or Dense Medium Separation Which is the Best?

Dense Media Separation – a Valuable Process for

Jun 15, 2018 The “Condor” Dense Media Separator is a dynamic cylindrical separator In the DMS unit, the dense media is pumped from the lower end of the cylinder (medium inlet 1 and 2) as shown in Figure 1 Utilising gravitational and centrifugal forces, a tangential or involute inlet forces the media to spiral alongside the wall, creating a vortex While dense media separation is used extensively in the coal industry and somewhat commonly in the diamond industry, its use has not been extensively exploited for other mineral systems The response of upgrading low grade sulfide based nickel ores using dense media cyclones has been reported on RECENT DEVELOPMENTS IN PRECONCENTRATION USING Dense Media Separation is a wellknown sinkfloat method and technology used within the coal, iron ore and diamond industries In the process of Dense Media Separation in diamonds, a powdered ferrosilicon (which is an alloy of iron) is suspended in water to form a very defined pulp density (heavy liquid), close to the density of diamond (352 g Dense Media Separation of Diamonds – DMS Powders

Ferrosilicon Frequently Asked Questions DMS Powders

Dense Media Separation is a sinkfloat method used within the coal, iron ore and especially diamond industries The powdered ferrosilicon is suspended in water to form a very specific pulp density (heavy liquid), close to the density of diamonds (352 g/cm3)Dense Media Separation (DMS) Plants In a Dense Media Separation (DMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (352 g/cm3), to which the diamond bearing material is added to begin the separation process of the heavier minerals from the lighter materialProcessing Methods Diamcor Mining IncJan 01, 2018 "South Africa possess the biggest fluorspar reserves in the world followed closely by China In light of the current commodity downturn this paper explores the use of Dense Media Separation (DMS) as a coarse preconcentration method for two fluorspar deposits located in South Africa in which the dominant gangue is carbonate present in the form of dolomite and calcitePreConcentration of Fluorspar Using Dense Media Separation

Dense Media Separation (DMS) sgs

Title: Dense Media Separation (DMS) Subject: SGS offers full capabilities in dense media separation for the recovery of diamonds Our DMS plant facilities are fully secured in locked compounds and comply with all applicable health, safety and environmental regulationsthe high separation densities required LOW UNIT VALUE OF IRON ORE The major ironore producers of the world mine massive highgrade orebodies, and sell their products after only crushing and screening of their runofmine ore Without thesacrifice ofore reserves, this is not possible with South Mrican deposits The relatively longTheuseofheavymediumseparationinthe Dense medium separation (DMS) is one of several preconcentration methods used for early waste rejection from runofmine ores at relatively coarse particle sizes prior to additional milling and beneficiation DMS has been used extensively in the coal, diamonds, mineral sands, base metals and iron ore industries to produce either a final product or as aDense media separation – a valuable process for

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 Feed for the dense media separation must be hard and compact with non porous gangue material Heavy media cyclone – The process is used for iron ore fines with size range of 02mm to 6 mm The cyclone type separator utilizes centrifugal as well as gravitational forces to make separation between ore and gangue materialDense media separation utilises a medium with a density in between the density of the ore and the gangue (commercially worthless) particles When introduced to this medium, particles either float or sink, depending on their density, as relative to the medium gravity density separators for minerals