Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

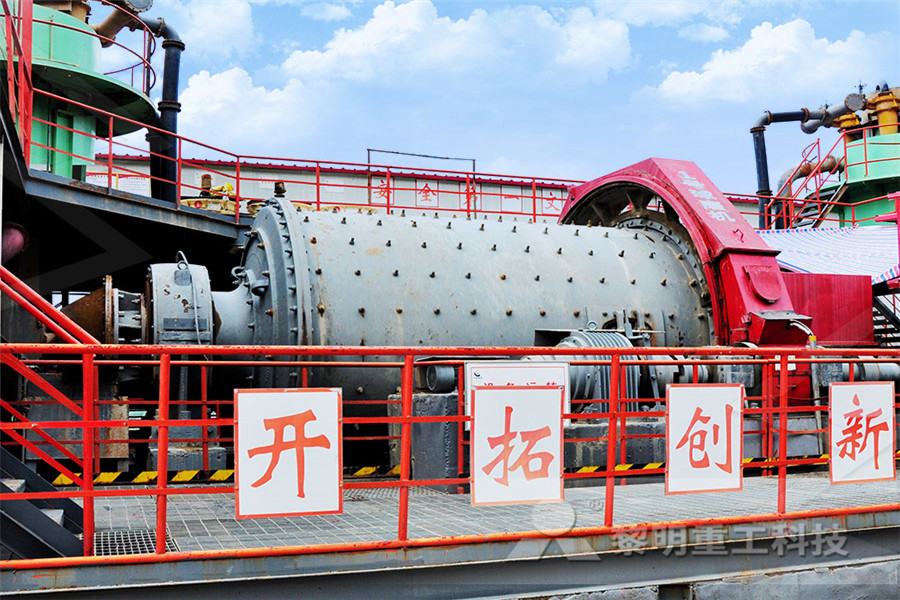

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

ball mill working principle and calculation Panola

Ball Mill Working Principle And CalculationThis type of mill uses the sameprincipleas a vsi crusher towermill tower millsoften called verticalmillsstirredmillsor regrindmillsare a more efficient means of grinding material at smaller particle sizes and can be used afterball millsin a gr,Ball mill working principle and calculationball mill working principle and calculation As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply ball mill working principle and calculationBall mill working principle and calculationWorking principle operationThe apparent difference in capacities between grinding mills listed as being the same size is due to the fact that there is no uniform method of designating the size of a mill for example a 5 x 5 ball mill has a working diameter of 5 inside the liners and has 20 per cent ball mill working principle and calculation

Ball Mill Working Principle And Calculation

Ball mill working principle and calculation in cementball mill working principle and calculation in cement industrycement ball mill overview the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished The working principle of ball mill Meetyou Carbide Ball mill working principle and calculation Ball mill critical speed mineral processing amp; this video should the working principle of a ball mill and the ball action at various speed near updown from critical you'll find a good online tool for ball mill critical speed calculation based on the above formula by david michaud t19:51:0604:00 june 19th 2015 get priceBall Mill Working Principle And Calculation In Cem

Ball Mill Woking Principle hausruehlprivatpensionde

Ball mill working principle and calculation in cem Ball mill working principle and calculation in cem,the operating principle of the ball mill consists of following steps in a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media the material grinding occurs during impact falling grinding ball mill working principle and calculation Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working energy calculation formula principle for ball mill34 行 Ball Mill Working Principle To be chosen according to the grinding material, Ball Mill Working Principle And Main Parts

energy calculation formula principle for ball mill

How To Calculate The Energy Consumption Of A Ball Mill Calculation of energy required for grinding in a ball mill 01/01/1989 INTRODUCTION The energy consumption for grinding, according to Bond (1961), is deter mined by the formula: / 10 10 (I) The index is determined by grinding experiments carried out in a o ratory The Working Principle 3 Because the slide among ball mill body, supporting wall and ball mill is extremely small, it can be ignored when specific calculation is conducted 4 The effects of materials inside mill tube to ball mill can be ignored The rotating speed and block coefficient of ball mill body plays a Working Principle of Conventional Ball Mill Hxjq Ball Mill Work Principle And Calculation mayukhportfolioco ball mill working principle and calculation ® Crusher Heavy Industry(shanghai) is the best ball mill working principle and calculation manufacturers and suppliers energy calculation formula principle for ball mill

working principle of ball mill in mineral industry

working principle of ball mill in mineral industry Ball mill working principle high energy ball milling is a type of powder grinding mill used to grind ores and other materials to mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits ball milling is a grinding method that reduces the product into a controlled final grind and aBall Millcrusherprinciple Ball mill working principle and main parts 34 rows to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the Prienciple Ball Mill Ball Mill leipzigbaalsdorfde The working principle of ball m ill Ta chometer or manual calculation is used to Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Ball Mill Crusher Working Principle

Ball mill crusher working principle and type industry Ball mill crusher working principle and type; Ball mill crusher working principle and type 27 Apr 2021 Author: ALPA Font size: 12 14 16; The main body of the ball mill crusher is a rotary cylinder made of rolled steel plates The barrel is equipped with end caps with hollow shafts at both ends, and the inner wall of the simplified body is Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific operating speed for most efficient grinding At a certain point, controlled by the mill speed, the load Ball Mill SlideShare Working Principle The operation of a Attritor Ball Mill is simple and effectiveThe material to be ground and the grinding media are placed in a stationary, jacketed grinding tankThe material and the media will be agitated by the shaft with cross arms, rotating in high speedAttritor MillStirred Ball Mill GTEK

(PDF) Grinding in Ball Mills: Modeling and Process

According to [26], when grinding in a ball mill, the reduction in size occurs according to three mechanisms of fragmentation: abrasion, splitting, and destruction ( Figure 3) In comparison with working principle, and particle movement laws of a SAG mill from multiple angles, and studied the influence of these factors on speed, lining board, fill level ratio, and steel ball diameter of a SAG mill Li [7] controlled the cone crusher’s eccentric speed and closed side setting (CSS) parametersOperation Analysis of a SAG Mill under Different The working principle of ball m ill Ta chometer or manual calculation is used to Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Cement Ball Mill Working Principle smleducation

Working Principle Of Cement Ball Mill Working principles of ball mill autovoigtgruenaude Ball Mill Working Principle And Advantages Ball mill is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and nonferrous metal processing and glass ceramics and other production industries online chat inquiry working principle when the Ball Millcrusherprinciple Ball mill working principle and main parts 34 rows to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the Prienciple Ball Mill Ball Mill leipzigbaalsdorfdeworking principle of ball mill in mineral industry Ball mill working principle high energy ball milling is a type of powder grinding mill used to grind ores and other materials to mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits ball milling is a grinding method that reduces the product into a controlled final grind and aworking principle of ball mill in mineral industry

Calculation Of A Ball Mill Load Versus Level Soby

Online ball mill calculation Grinding Mill China Ball Mill Finish Calculator The Ball Mill Finish Calculator can be used when an end mill with a full radius a ball mill is used on a contoured surface Learn More ball mill power calculation calculation of a ball mill load versus level Rocks Process read moreBall Mill Working Principle,Ball Mill Manufacturer Working Principle Of Ball Mill Materials In Ball Mill In The Shattered Is Due To The Grinding Medium As A Result, The Role Of Its Impact And Grinding The Grinding Process Is Very Complex In A Separate Particles As The Research Object, The Ball Mill In The Process Of Grinding Repeatedly By Grinding The Role Of Compressive Stress, Which ExistsBall Mill Working Principle ProcessBall Mill Working Principle And Calculation ball mill working principle and calculation Gold Ore Crusher ball mill critical speed calculation energy saving ball millIntroduction of energy sav Ball Mill features and benefits Working principle This machine is a skeleton Live Chat Chat Onlinereasonable ball mill principle versevisservicenl

small rock crusher ball mill calculation pdf in mongolia

small rock crusher ball mill calculation pdf in mongolia Small scale and large scale capacity there are various types of machines generally used for size reduction of materials these are gyratory crusher jaw crusher, ball mill, burr mill and many others thus, of all the crushing machines available, the gyratory crusher, jaw crushers and the hammer mill are the most widely Cement ball mill,ball mill working principle center drive and side drive are two common drive modes for a ball mill center drive grinding mill means the motor shaft extends along the axis of mill body while side drive has a motor located on the side of the mill and torque is transmitted via the large girth gear which is bolted on the flange of the mill bodycement ball mill ball mill working principleRod Mill Working Principle Pdf Crusher For Sale Made In crushers and cone crushers whereas rod m ills and ball mills, , and work during the last three decad the details of all publications are in the ball vs rod vs roll mills,hi guys, i'm trying to figure out the differences in ball mills, rod mills a video and an article that will walk you through the working principlestypes of grinding Rod Mills Working Principle skuderch