Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

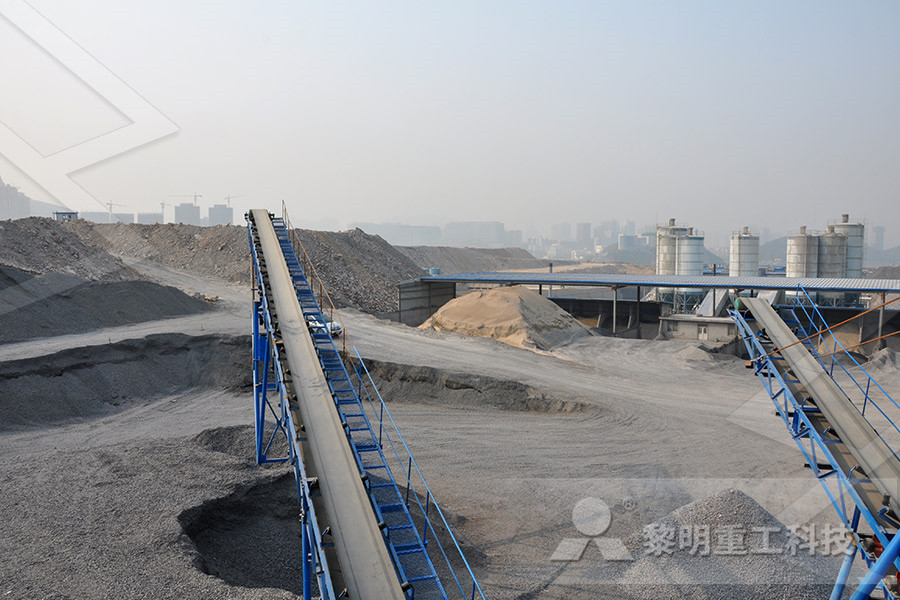

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

(PDF) Precission plunge milling for angled vertical

milling The vertical raster milling or plunge milling is based on thre e phases: the first phase has its foundation on tool compensation, the second phase is when the tool g oes down executingMilling cutters are cutting tools typically used in milling machines or machining milling versus climb milling; 33 Cutter location (cutter radius compensation) They are the most common tool used in a vertical mill They are shaped like a piece of pipe (but with thicker walls), with their cutting edges on the inside surface Read morevertical milling cutters for internal radius This particular toolpath strategy designed, with a commercial CAM program, for finishing the vertical and angled walls, offers a better surface roughness, and a better dimensional control (accuracy), both for the milling tool and also for the work piecePrecission plunge milling for angled vertical walls, on

Smart Strategies for Steep/Shallow Milling

vertical walls Figure 2 Parallel finishing works well on flat or shallow surfaces but causes a problem with scallops when the surface normal is close to that of the parallel intersecting planes Decreasing the distance between the intersection planes can reduce the scallops on walls but leads to redundant machining of flatter zones Surface Milling in FeatureCAM allows you to dictate how the tool behaves when rolling over edges These options are located in the Edges tab To fix your issue, go into the edges tab and select Cut to bottom This will allow the tool to waterfall over those edges where there are vertical walls Problem with vertical walls in finish surface milling A vertical boring mill is a machine used to bore holes in metals, usually iron or steel They are very similar to a typical milling machine, where the workpiece is kept stationary, and milling tools rotate at high speeds These tools are very similar to drill bits on a drill press and come in many different shapes and sizes to accommodate a What is a Vertical Boring Mill? InfoBloom

Structure of vertical milling machine ram adapter

It helps to cur the milling head within a vertical plane and a horizontal) plane to flexibly perform milling process in any angle In a conventional ram adapter (1), as shown in FIG 1, locking bolts (11) and adapter pivot stud (12) are used to insert from one side (21) of the overarm (2) through the ram adapter (1) into the other side (22) to become locked up by means of a locknut (13) According to Li et al , in the milling process, the micro thin wall does not vibrate at a single frequency, and the amplitude of the vibration of the micro thin wall is more significant when the milling frequency is within 10 times of the milling frequency The impact of the milling tool on the micro thin wall will increase the maximum deformation of the micro thin wall in the direction of deviation from the Research on deformation law and mechanism for Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material The milling process requires a milling machine, workpiece, fixture, and cutter The workpiece is a piece of preshaped material that is secured to the fixture, which itself is attached to a platform inside the milling machineMilling Process, Defects, Equipment

vertical milling cutters for internal radius

Milling cutters are cutting tools typically used in milling machines or machining milling versus climb milling; 33 Cutter location (cutter radius compensation) They are the most common tool used in a vertical mill They are shaped like a piece of pipe (but with thicker walls), with their cutting edges on the inside surface Read more the inner walls of the mill because of the centrifugal force dominating over centripetal force For large scale production tumbler mills are more economical when compared to the other high energy [26] While a number of ball mills ingenious milling devices were developed early in the century, the one high energy ball mill that has been adopted byMechanical Milling: a Top Down Approach for the inner walls of the vial and do not fall down to exert any impact force Therefore, the maximum speed should be just below this critical value so that the balls fall(PDF) Mechanical alloying and milling / C

Design for Machining: Restrictions

Vertical milling machines have a spindle axis and cutting tool that is aligned vertical to the machines’ bed Inner Edges In designing inner edges, the most commonly recommended vertical corner radius is onethird of the cavity depth or more Thin walls can be tricky as decreasing the wall thickness reduces the stiffness of the A vertical boring mill is a machine used to bore holes in metals, usually iron or steel They are very similar to a typical milling machine, where the workpiece is kept stationary, and milling tools rotate at high speeds These tools are very similar to drill bits on a drill press and come in many different shapes and sizes to accommodate a What is a Vertical Boring Mill? InfoBloom There are other more specific milling types, such as the following: Turn milling, in which the feed movement is the part rotation instead of a linear movement Thread milling to produce inner or outer threads (see Figure 33) Highfeed milling, a special face milling operation with milling tools with a very low position angle (K r), as will be explained in Section 366Milling ScienceDirect

USE OF TAPECONTROLLED MILLING MACHINES TO

The walls, 11, 12 and webs 21 of the pattern 10 have a horizontal planar upper edge surface 21 The vertical inner surfaces 20 of the several cavities of the pattern 10 flow smoothly into each other at internal arcuate fillets 25 of generous radius somewhat smaller than the external fillets 14 and formed about vertical Milling the inner diameter of a disc with straight (vertical) walls A ring of material is slowly removed as the table rotates and the end mill is gently plunged down over time The inner diameter is milled out using the same technique as the outer diameter However, unlike StreamHawk Wireless Video Explorer, Page 4 Robot Diaphragm Walls 07/10/09 Rev 6 Diaphragm walling refers to the insitu construction of vertical walls by means of deep trench excavations Stability of the excavation is maintained by the use of a drilling fluid, usually a bentonite suspension The walls are constructed in discrete panel lengths ranging typically between 25m andDiaphragm Walls Skanska

Calculation of "wallinner" path Ultimaker Cura

Each dimensions of my design were accurately print, whether outer or inner side I am now using Cura (version 1501) I noticed that inner dimensions, especially for circles, are much lower than it should be It looks like as if there were no compensation of the filament size in the calculation of the "wallinner The flow conditions at the inner walls of the mill were studied with the carbon black A quite abrupt loss of speed is found at the radial direction from milling chamber inner wall to product outlet tube at every height of the light cut The shape of the vertical crosssection of the comminution zones is obviously rectangular and a quite Visualization of flow conditions inside spiral jet mills For example in Local Milling, if you are removing material left over in a pocket with slanted walls, specifying the value of the SLOPEANGLE less than the wall slope will make the tool machine the bottom edges of the pocket first, and then remove the material in the corners between the wallsMilling Parameters PTC

Milling Parameters Polynet

Milling Parameters FOLLOWHARDWALLSThe shape of each cut follows the shape of the walls of the volume, maintaining fixed offset between the respective points of two successive cuts If set to LOOPCONNECT, the neighboring endpoints are connected by vertical loops, with the tool leaving and entering material tangent to the surface being There are other more specific milling types, such as the following: Turn milling, in which the feed movement is the part rotation instead of a linear movement Thread milling to produce inner or outer threads (see Figure 33) Highfeed milling, a special face milling operation with milling tools with a very low position angle (K r), as will be explained in Section 366Milling ScienceDirectThe tubing size was 45” with a nominal inner diameter of 3958” and the Well Miller milled the orientation sleeve restriction successfully using a 39” bit on run two and a 41” bit on run three For the fourth run, the operator decided to mill the scale between 900 ft and 1,500 ft using a 39” Expandable BitMilling and polishing Welltec

What is a Vertical Boring Mill? InfoBloom

A vertical boring mill is a machine used to bore holes in metals, usually iron or steel They are very similar to a typical milling machine, where the workpiece is kept stationary, and milling tools rotate at high speeds These tools are very similar to drill bits on a drill press and come in many different shapes and sizes to accommodate a Feb18,2016 News News News In June 2016, we will put our new 5axis, vertical portal milling machine from TRIMILL into operation A few things still have to be implemented before thenKBW – NEWS VM 729 Strategies for material removal in laser milling P V Petkov, S Scholz and S Dimov Manufacturing Engineering Centre, Cardiff University, Queen's Buildings, The Parade, Newport Road, Cardiff, CF24 3AA, UK Abstract Laser milling with microsecond pulses is a thermal material removal process usually associated with detrimentalStrategies for Material Removal in Laser Milling

Calculation of "wallinner" path Ultimaker Cura

Each dimensions of my design were accurately print, whether outer or inner side I am now using Cura (version 1501) I noticed that inner dimensions, especially for circles, are much lower than it should be It looks like as if there were no compensation of the filament size in the calculation of the "wallinner A good design practice is to align all features of your model (holes, cavities, vertical walls etc) to one of the 6 main principal directions See this rule as a recommendation and not a restriction though, as 5axis systems offer advanced workpiece holding capabilitiesHow to design parts for machining Hubs