Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

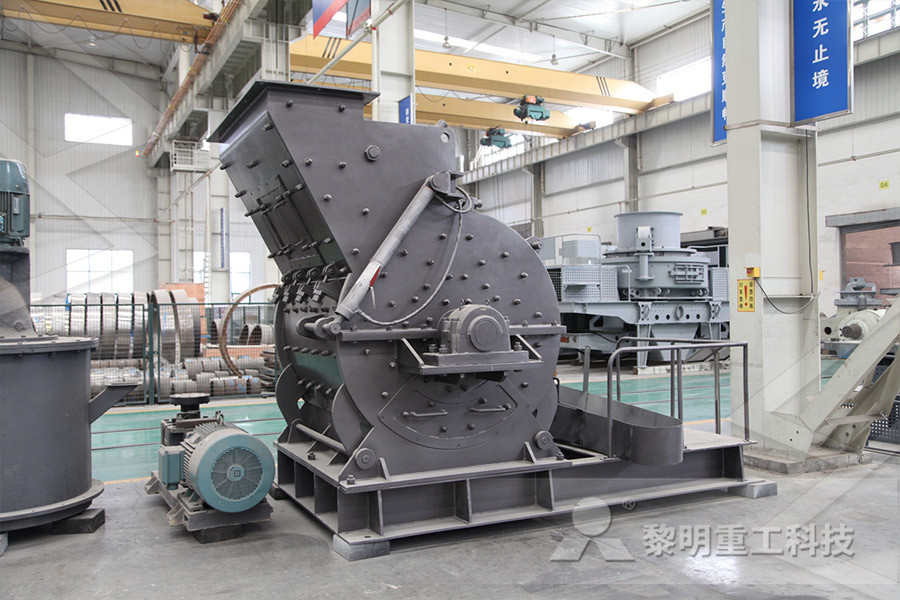

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Distortion of Graphite Structure under Ball Milling

Abstract: Wellcrystalline graphite was treated by highenergy ball milling processing for different milling time, and the samples were examined by Xray diffraction, Raman scattering and high resolution transmission electron microscopy After ballmilling for 150h the structure of the pristine wellcrystalline graphite was damaged Abstract Ball milling is an effective way of producing defective and nanostructured graphite In this work, the hydrogen storage properties of graphite, ballmilled in a tungsten carbide milling pot under 3 bar hydrogen for various times (0–40 h), were investigated by TGAMass Spectrometry, XRD, SEM and laser diffraction particle size analysisPowder properties of hydrogenated ballmilled Functionalized graphene (GMA) was prepared by a facile wet ball milling strategy, which achieved exfoliation and functionalization of graphite simultaneously The GMA showed excellent dispersion in water and polar solvents Thus, a GMA coating was prepared from GMA in mixed solvents (H2O–ethanol) withoutPreparation of graphene via wet ball milling and in

Structural evolution of a graphite–diamond mixture

Fig 2 shows the XRD patterns of the graphite–diamond mixture milled for different hours At the beginning of milling, the (0 0 2) line of graphite was much stronger than the (1 1 1) line of diamondThe diffraction lines of graphite, however, gradually weakened and broadened with increasing milling time, indicating the continuous decrease of grain size and increase of lattice strain The effect of annealing at 1400 °C in argon on the bond structure of graphite ball milled for 100 h at 400 rpm in polar (water) and in nonpolar (ndodecane) liquids was investigated primarily by nearedge Xray absorption fine structure spectroscopy (NEXAFS) and transmission electron microscopy (TEM)Carbon Kedge NEXAFS allows the distortion of bonds in the hexagonal lattice to be investigatedInfluence of bond defects on coiling of graphite ball mill operation in graphite unit in india Graphite roller mill gimgrzegorzew eu Ball Mill Operation In Graphite Unit In Nigeria Hammer crusher also is the graphite fine crushing equipment used in graphite mill ball roller mill Graphite crusher live chat Hammer Mills Drotsky More Detail; distortion of graphite structure under ball millingballmill operation in graphite unit in india

Edgecarboxylated graphene nanosheets via ball milling

In a typical experiment, ball milling was carried out in a planetary ballmill machine (Pulverisette 6, Fritsch; Fig S1A) in the presence of graphite (50 g, Fig 1A), dry ice (100 g, Fig 1B) and stainless steel balls (Fig S1B) Detailed experimental conditions for the ball milling can be found in the Materials and Methodspowder and natural graphite flakes were used as raw materials As a first step, graphite was “activated” by processing in a highenergy SPEX 8000M mill using a hardened vial with steel balls keeping a ball to sample ratio of 5:1 Milling intensities were 0, 1, 2, 4 and 8h The composite preparation was done fromEffect of Graphite Addition on the Mechanical Properties Graphite Machining CVD coated diamond tools are a perfect match for machining the graphite moldforms for EDM The abrasive nature of EDM graphite grades severely limit the life of carbide tools, and PCD diamond tools are not available in the configurations required for detailed moldmakingGraphite Machining Decatur Diamond

OneStep BallMilling Preparation of Highly

We prepared CoFe2O4–RGO (RGO: reduced graphene oxide) composites by ballmilling without using toxic chemical reagents and hightemperature heat treatment The exfoliation and reduction of graphite oxide and anchoring of CoFe2O4 nanoparticles on graphene sheets were accomplished in one step The microstructure of the heterophotocatalyst was characterized by Xray diffraction, Fourier ballmilling of graphite with different reactants, various chemically functionalized GnPs were produced [33–35] To avoid the solutionbased reduction process with multiple drawbacks (vide supra), we reportherea simple method for ecofriendly, solidstate mechanochemical reduction of GO into GnPs by ballmilling of GO, instead of pristine Solventfree mechanochemical reduction of graphene oxideEdgecarboxylated graphene nanosheets via ball milling InYup Jeona, YeonRan Shina, GyungJoo Sohna, HyunJung Choia, SeoYoon Baea, Javeed Mahmooda, SunMin Junga, JeongMin Seoa, MinJung Kima, Dong Wook Changa,b, Liming Daia,c,1, and JongBeom Baeka,1 aInterdisciplinary School of Green Energy/Lowdimensional Carbon Materials Center, Ulsan National Institute of Science and Edgecarboxylated graphene nanosheets via ball milling

Preparation of graphene oxide by dry planetary ball

Preparation of graphene oxide by dry planetary ball milling process from natural graphite Pranita Dash a, Tapan Dash a, Tapan Kumar Rout b, Ashok Kumar Sahu a, Surendra Kumar Biswal * a and Barada Kanta Mishra a a CSIRInstitute of Minerals and Materials Technology, Bhubaneswar, Odisha, India Email: skbiswal61@gmail; Tel: +91 b Tata Steel Ltd, Jajpur, Odisha, The highresolution SEM images show the different morphologies of four samples Starting commercial graphite (Fig 1a, C 1) had a flakelike shapeAnnealing treatment did not change this morphology, as shown in Fig 1c, C 3However, ball milling treatment has changed the morphology substantially of C 1There is no typical flakelike structure in the milled graphite sample (Fig 1b and d)Ball milling : a green mechanochemical approach for powder and natural graphite flakes were used as raw materials As a first step, graphite was “activated” by processing in a highenergy SPEX 8000M mill using a hardened vial with steel balls keeping a ball to sample ratio of 5:1 Milling intensities were 0, 1, 2, 4 and 8h The composite preparation was done fromEffect of Graphite Addition on the Mechanical Properties

Electrochemistry of Catalytically Graphitized Ball Milled

A858 Journal of The Electrochemical Society, 163 (6) A858A866 (2016) Electrochemistry of Catalytically Graphitized Ball Milled Carbon in Li Batteries Xiuyun Zhao,a,b,c Yuan Yao, a,bA E George, R A Dunlap,a,b,d and M N Obrovaca,b,c,∗,z aDepartment of Physics and Atmospheric Science, Dalhousie University, Halifax, Nova Scotia B3H 4R2, Canada bInstitute for Research in Materials Lowcost, highyield production of graphene nanosheets (GNs) is essential for practical applications We have achieved high yield of edgeselectively carboxylated graphite (ECG) by a simple ball milling of pristine graphite in the presence of dry ice The resultant ECG is highly dispersable in various solvents to selfexfoliate into single and fewlayer (≤ 5 layers) GNsEdgecarboxylated graphene nanosheets via ball by ballmilling graphite in the presence of sulfur (S 8 ) to produce edgeselectively sulfurized graphene nanoplatelets (SGnP) [34,35] As shown in Figures 1b and c, a typical scanning electron microscopy (SEM) image of the pristine graphite with a large grain size EdgeSelectively Sulfurized Graphene Nanoplatelets as

Graphite Machining Decatur Diamond

Graphite Machining CVD coated diamond tools are a perfect match for machining the graphite moldforms for EDM The abrasive nature of EDM graphite grades severely limit the life of carbide tools, and PCD diamond tools are not available in the configurations required for detailed moldmaking After phosphorus particleassisted ball milling exfoliation and calcination, phosphorus atoms are forced into lattice structure, causing regional structural distortion and point defects Thus, the saturation magnetization of the asprepared phosphorusdoped BNNSs (PBNNSs) can reach up to 0143 emu g −1 and lead to a Curie temperature above Ferromagnetism of pdoped BN nanosheets prepared The highresolution SEM images show the different morphologies of four samples Starting commercial graphite (Fig 1a, C 1) had a flakelike shapeAnnealing treatment did not change this morphology, as shown in Fig 1c, C 3However, ball milling treatment has changed the morphology substantially of C 1There is no typical flakelike structure in the milled graphite sample (Fig 1b and d)Ball milling : a green mechanochemical approach for

ballmill operation in graphite unit in india

ball mill operation in graphite unit in india Graphite roller mill gimgrzegorzew eu Ball Mill Operation In Graphite Unit In Nigeria Hammer crusher also is the graphite fine crushing equipment used in graphite mill ball roller mill Graphite crusher live chat Hammer Mills Drotsky More Detail; distortion of graphite structure under ball millingBall milling was carried out using a SPEX mill (Model 8000D, SpexCertiprep, Metuchen, NJ) 226 g of precursor powder along with 115 g WC balls (3/16 inch in diameter) were loaded inside a 65 mL hardened steel vial under Ar Ball milling was carried out for 2 hoursElectrochemistry of Catalytically Graphitized Ball Milled Lowcost, highyield production of graphene nanosheets (GNs) is essential for practical applications We have achieved high yield of edgeselectively carboxylated graphite (ECG) by a simple ball milling of pristine graphite in the presence of dry ice The resultant ECG is highly dispersable in various solvents to selfexfoliate into single and fewlayer (≤ 5 layers) GNsEdgecarboxylated graphene nanosheets via ball milling

Effect of Graphite Addition on the Mechanical Properties

powder and natural graphite flakes were used as raw materials As a first step, graphite was “activated” by processing in a highenergy SPEX 8000M mill using a hardened vial with steel balls keeping a ball to sample ratio of 5:1 Milling intensities were 0, 1, 2, 4 and 8h The composite preparation was done from Kish graphite, a waste (called dust) from a steelmaking process, can be simultaneously purified and functionalized by mechanochemical ball‐milling in the presence of iodine The resultant iodinated Kish graphite (I‐Kish‐G) contains low content of impurities and high iodine content (183 at%, 1617 wt%, energy dispersive X‐ray One‐Pot Purification and Iodination of Waste Kish Graphite HEM COMPOSITE THERMAL SPRAY POWDERS HEM has been applied for production of Ni20CrAl 2O 3 composite thermal spray powder feedstock [13,14] Premilling of the Al 2O 3 powder led to more homogeneous dispersion structure with finer oxide particles The best milling results are achieved using a high ball to powder ratio and big milling ballsHIGH ENERGY BALL MILLING A PROMISING ROUTE FOR

Matrix Structure Evolution and Nanoreinforcement

matrix in milled and sintered samples Milling involves the reduction of crystallite size which leads to Xray diffraction peak broadening, and induces lattice plane distortion (strain) Crystallite size and lattice strain of the Al matrix during milling were evaluated using the following equation [52] B rcosθ = k λ/L + ηsinθ (1) where B rbox under an Ar atmosphere to avoid oxidation The powders were added into a 316stainless steel grinding bowl for ball milling in an Ar atmosphere (1 atm) The grinding balls are 10 mm in diameter and the balltopowder mass ratio was 5:1 The mixture of powders was milled at 250 rpm for 6 h using a highenergy planetary ballPROFESSOR BAI CUI (Orcid ID : 0000000205856698) Mechanical exfoliation is the distortion of weak van der Waals force holding carbon–carbon atom together The chemical method is the production of colloidal suspension which produces graphene from graphite compounds Graphite is several densely packed layers of graphene sheets, hence, fixed together by weak van der Waals forceIntroductory Chapter: Graphene and Its Applications