Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

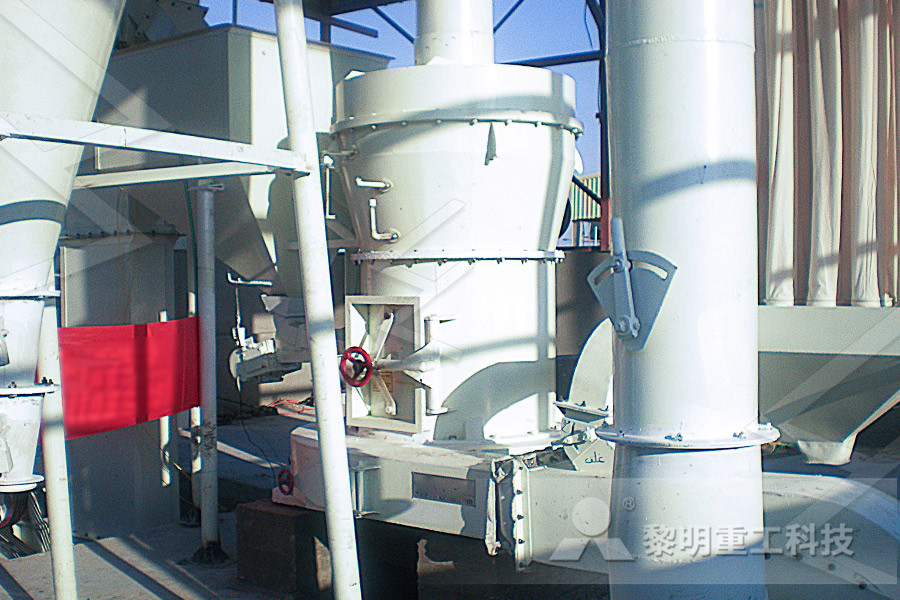

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Plant Layout Plant Layout in Production And

Plant Layout in Operation Management Plant layout refers to the physical arrangement of production facilities It is the configuration of departments, work centers and equipment in the conversion process It is a floor plan of the physical facilities, which are used in productionView 3 Plant Layoutpdf from PSY 2018 at Harvard University plant layout Production and Operation Management (BBA 303) BBAV semester Dr Akanksha Upadhyaya Department of Management3 Plant Layoutpdf plant layout Production and Production and operations management Tuesday, March 17, 2009 Plant Layout Ideal plant layout Acc to F G Moore “A Good plant layout is one which allows material rapidly directly for processing This reduces transport handling, clerical and other costs down per unit , space requirement are minimised and it reduces idle machine and Production and operations management: Plant Layout

Operation Management : Facility Layout, Types of Layouts

Operation Management : Facility Layout, Types of Layouts Plant layout design starts along with factory building All the facilities like equipments, raw materials, machinery, tools, futures, workers, etc are placed at cooperation with employees while in production as it will create a multiplier effect on production In this way, plant layout is a joint product of both the disciplines, namely, engineering and management Characteristics of an Efficient Layout The designing of a plant layout should be such that it should maximize the return and minimize the cost of production The following are the characteristics of a plant layout 1 Smooth flow of Plant Layout Meaning Top 10 Characteristics of (i) Plant layout is very complex in nature; because it involves concepts relating to such fields as engineering, architecture, economics and business management (ii) Most of managers now realize that after the site for plant location is selected; it is better to develop the layout and build the building around it – rather than to construct Plant Layout: Concept, Objectives, Principles and Types

Plant Layout: Meaning, Need and Importance

In the words of Sansonneti and Mallick (Factory Management, Vol 103) “It is placing the right equipment, coupled with right place, to permit the processing of a product unit in the most effective manner, through the shortest possible distance and in the shortest possible time” The last definition seems to be most appropriate Need of Plant Layout:Fixed Position Layout Type # 1 Plant Layout: Plant layout means the disposition of the various facilities (equipments, material, manpower, etc) and services of the plant within the area of the site selected previously Plant layout 5 Main Types of Plant Layout Industries The layout is flexible as change in job design and operation sequence can be easily incorporated 3 Adjustments can be made to meet shortage of materials or absence of workers by changing the sequence of operations Disadvantages of Fixed position layout 1 As the production period being very long so the capital investment is very high 2Types of layout Introduction to Operations

3 Plant Layoutpdf plant layout Production and

View 3 Plant Layoutpdf from PSY 2018 at Harvard University plant layout Production and Operation Management (BBA 303) BBAV semester Dr Akanksha Upadhyaya Department of ManagementADVERTISEMENTS: After reading this article you will learn about: 1 Meaning of Plant Layout 2 Factors Considered for Plant Layout 3 Analytical Tools 4 Advantages 5 Layout of Services 6 Objectives of Plant Layout and Material Handling 7 Types of Plant Layout Problems 8 Characteristics 9 Principles 10 Factors Influencing 11 Types 12 MachineRequirements 13 []Plant Layout: Meaning, Factors and Tools In the words of Sansonneti and Mallick (Factory Management, Vol 103) “It is placing the right equipment, coupled with right place, to permit the processing of a product unit in the most effective manner, through the shortest possible distance and in the shortest possible time” The last definition seems to be most appropriate Need of Plant Layout:Plant Layout: Meaning, Need and Importance

What Is Plant Layout? Types, Objectives, Process

Plant layout is the overall arrangement of the production process, storeroom, stockroom, toolroom, material handling equipment, aisles, racks and substores, employee services and all other accessories required for facilitation of the production in the factory PLANT LAYOUT AND MATERIAL HANDLING Plant layout refers to the physical arrangement of facilities It is the configuration of departments, work centers and equipment in the conversion process The overall objective of the plant layout is to design a physical arrangement that meets the required output quality and quantity most economicallySCOPE OF PRODUCTION AND OPERATIONS Plant layout refers to the physical arrangement of production facilities It is the configuration of departments, work centres and equipment in the conversion process It is a floor plan of the physical facilities, which are used in production A plant layout study is an engineering study used to analyze different physical configurations for a Objectives and Principles of Plant Layout

Types of layout Introduction to Operations

The layout is flexible as change in job design and operation sequence can be easily incorporated 3 Adjustments can be made to meet shortage of materials or absence of workers by changing the sequence of operations Disadvantages of Fixed position layout 1 As the production period being very long so the capital investment is very high 2Fixed Position Layout Type # 1 Plant Layout: Plant layout means the disposition of the various facilities (equipments, material, manpower, etc) and services of the plant within the area of the site selected previously Plant layout begins with the design of the factory building and goes up to the location and movement of a work table5 Main Types of Plant Layout Industries Some companies are using digital twins of their facilities to simulate operation under different staffing levels and production scenarios This approach can support many aspects of operational planning, from evaluating the impact of changes to plant layout to determining the mix of skills that onsite teams will requireManaging a manufacturing plant through the

Optimization in Production Operations IISE

In particular, this essay focuses on the management of industrial, repetitive or continuous, bulk or discrete, high volume production operations In most production operations it is possible to define objectives quantitatively very well, which leads to the possibility Singh (2012) that observed that a good plant layout design facilitates the production process, minimizes material handling, time and cost, and allows flexibility of operations, easy production (PDF) PLANT LAYOUTS' ANALYSIS AND DESIGNIn this way, plant layout is a joint product of both the disciplines, namely, engineering and management Characteristics of an Efficient Layout The designing of a plant layout should be such that it should maximize the return and minimize the cost of production The following are the characteristics of a plant layout 1 Smooth flow of Plant Layout Meaning Top 10 Characteristics of

Lectures notes On Production and Operation Management

Production/Operation management is the process which combines and transforms various resources used in the production/operation subsystem of the organization into value added products/services in a controlled manner as per the policies of the organization Often, the deadline dates for delivery of production orders are a bugaboo to the management Plant layout is a significant factor in the timely execution of orders An ideal layout eliminates such causes of delays as shortage of space, longdistance movements of materials, spoiled work and thus contributes to the speedy execution of ordersThe importance of layout CiteManFixed Position Layout Type # 1 Plant Layout: Plant layout means the disposition of the various facilities (equipments, material, manpower, etc) and services of the plant within the area of the site selected previously Plant layout begins with the design of the factory building and goes up to the location and movement of a work table5 Main Types of Plant Layout Industries

Top 10 Factors influencing design of plant layout

For synthetic type of Production (cement and automobile industries), line layout is preferable 10 Management policies: Policies of the management relating to type of product, quality, scale of production, level of plant integration, type of production, possibility of future expansion etc, influence the type of layout to be adoptedProduction and Operation Management Dr MK Rastogi Laxmi means measurement method motion nature necessary normal Note objectives observed operations organisation output performance period plant plant layout preventive principles problems procedures production management production planning production process quantity range recording Production and Operation Management Dr MK Facility Layout After the site location decision has been made, the next focus in production planning is the facility’s layout The goal is to determine the most efficient and effective design for the particular production processFacility Location and Layout Introduction to Business

Optimization in Production Operations IISE

In particular, this essay focuses on the management of industrial, repetitive or continuous, bulk or discrete, high volume production operations In most production operations it is possible to define objectives quantitatively very well, which leads to the possibility Achieving realtime supply chain, order management and production performance visibility across all manufacturing operations Excelling at data collection to the machine, team and plant level including piloting Internet of Things (IoT) as a means to capture data in realtime10 Steps To An Effective Manufacturing Operations