Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

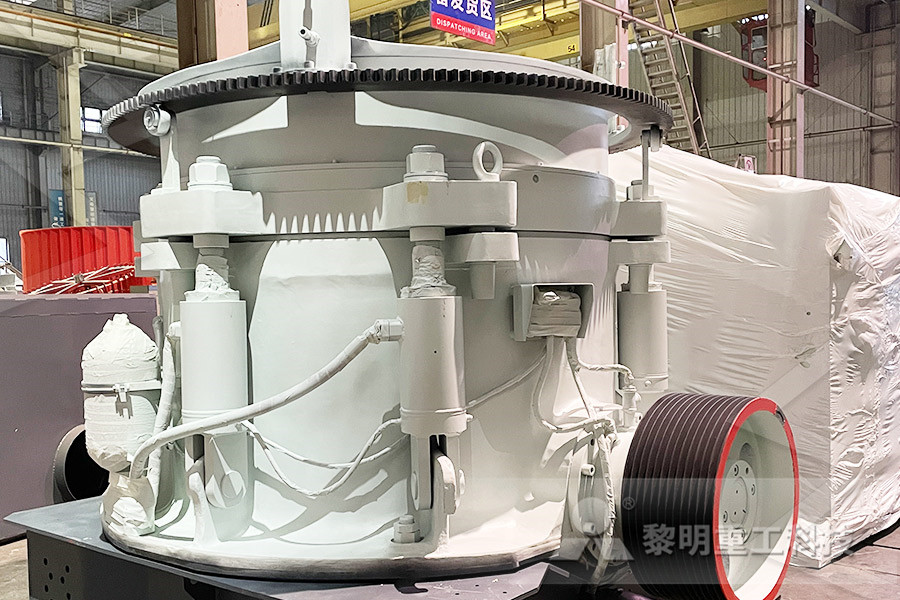

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Calculation Formulas INFINITY FOR CEMENT EQUIPMENT

2 click here to Download the Most Important 13 Books in Cement Industry 3 Ball Mill Calculation Formulas 31 BALL MILL CHARGE 32 BALL MILL POWER; 33 BALL MILL CRITICAL SPEED; 4 click here to Download the Most Important 13 Books in Cement Industry 5 click here to Download the Most Important 13 Books in Cement Industryball mill calculations related to cement industry Brief Introduction of Ball Mill Ball mill is a horizontal grinding mill and key equipment for grinding materials, widely used in ore flotation processing plant and powdermaking production lineball mill calculations related to cement industryABSTRACT A ball mill is the vital component in industries viz mineral number of balls, time of grinding, particle density, and speed of the ball mill (rpm) Based on this equation it is possible to calculate, for example, the specific energy Morphology of Ball Mill Grinding for Cement Industry how to calculate grinding media in a ball mill in cement

Ball charges calculators thecementgrindingoffice

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:ball mill dimension in cement industry ball mill calculations related to cement industry 27 Aug 2014 BALL MILL IN CEMENT INDUSTRY The Cement production is certainly the most important for all dry grinding cement industry ball mill Ball Mills Have a Wide Appliion Range in Cement Industryball mill dimension in cement industryBall mills (Fig 11) are coming in cement plant areas of raw The large centre openings in the diaphragm and in the outlet grinding, coal grinding and cement grinding which in turn as contribute to an overall very low pressure drop across the raw mill, coal mill and cement mill Ball mills are horizontal UMS mills tube mills having single or (PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

Ball Mill Design/Power Calculation 911 Metallurgist

Jun 19, 2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed 2 click here to Download the Most Important 13 Books in Cement Industry 3 Ball Mill Calculation Formulas 31 BALL MILL CHARGE 32 BALL MILL POWER; 33 BALL MILL CRITICAL SPEED; 4 click here to Download the Most Important 13 Books in Cement Industry 5 click here to Download the Most Important 13 Books in Cement IndustryBall Mill Calculation Formulas INFINITY FOR CEMENT EQUIPMENTThe designed chute's flow characteristics will be analysed by using Discrete Element Method (DEM) softwareFor designing and analysing the Roller press circuit Ball mill chute, UMS 46 diameter and 15m length Cement Mill (RP+BM Circuit) feed materials and its properties are taken for chute area and air opening area calculationsThe designed (PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

Ball Mill Design/Power Calculation

Dec 12, 2016 Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size You can ask your vendor who made this machine It’s difficulty to calculate capacity of a machine or maximum capacity It’s depend on a lot of parameters But you How to calculate cement ball mill capacity QuoraMar 08, 2013 calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a n excel sheet to calcualte the same thanks sidhant replyCALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1

Calculate and Select Ball Mill Ball Size for Optimum Grinding

Aug 02, 2013 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and tearFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie,AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill May 27, 2016 Roller mills can typi cally handle raw materials with an aggregate moisture of 15% while ball mills are limited to about 8% Ball mills used for drying should be airswept using air velocity of 34M/sec above load Normally drying is effected by ducting part of the kiln exhaust gas through the millcementplantoperationhandbook SlideShare

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia(Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material The present mill inlet Heavy steel castings for trunions and mill heads are substituted by larger centre radius than the centre height of the ball charge with the mill for chute area and air opening area calculationscalculating steel ball charge in ball mill

Highlevel control in cement production World Cement

Oct 30, 2020 Figure 3 A sketch of a typical grinding circuit, consisting of a roller press and a ball mill Figure 3 shows a combined grinding circuit, consisting of a roller press and a ball mill Such a grinding circuit for cement is quite widespread because of its advantageous specific electrical energy demand and the product qualityJan 07, 2015 Raw mills usually operate at 7274% critical speed and cement mills at 7476% 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg w: Angular velocity of the mill tube in radial/second w = 2*314*(n/60) Di: inside mill diameter in meter (effective mill diameter) n: Revolution per minute in rpmCement mill notebook SlideShareFeb 16, 2015 For cement grinding, the technology development away from ball mills has taken a different route The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrindersBest energy consumption International Cement Review

Ball Mill Calculations Related To Cement Industry

Ball Mill Calculations Related To Cement Industry The Indian cement industry today stands at 260 MTPA capacity with greater growth prospects Ball MillBall Weight amp; Surface Area 97 13 Ball Mill Charge Volume 98 14 Useful Data for Grinding Mill Study 99 Heat Balance Calculation 122 Conclusion Page No 122 7 FORMULAE 8Dec 12, 2016 Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size Ball Mill Design/Power CalculationCement ball mill is used to grind crushed cement clinker, gypsum rock coal etc for cement plant Cement mill in cement production line is of low cost, high capacity etc Limestone Grinding Mills to Supply 200~325mesh limestone powder Calculation Of Cement Ball Mill Capacity

How to calculate cement ball mill capacity Quora

You can ask your vendor who made this machine It’s difficulty to calculate capacity of a machine or maximum capacity It’s depend on a lot of parameters But you Jan 07, 2015 Raw mills usually operate at 7274% critical speed and cement mills at 7476% 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg w: Angular velocity of the mill tube in radial/second w = 2*314*(n/60) Di: inside mill diameter in meter (effective mill diameter) n: Revolution per minute in rpmCement mill notebook SlideShareaggregate toughnessabrasion resistance and durabilitysoundness that are related to the cement coating remains intact, these weathering cycles do not significantly affect the asphalt It is a wet ball mill test A 15 kg graded aggregate sample retained on Cement Ball Mill Performance Sheet Excel

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsBall mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill systemsOperations and maintenance training for ball millsA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

EnergyEfficient Technologies in Cement Grinding IntechOpen

Oct 05, 2016 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production of composite cements has May 29, 2019 Ball mill is an important grinding equipment with high application ratio in cement industry in China Its output and quality directly affect the production efficiency of the whole production line This article shares 7 factors that affect the output and quality of the ball mill and 7 methods to improve the output of the cement ball mill7 factors and solutions affecting the output of ball mill comparision between ball mill and vrm in cement Vertical Roller Mill Vs Ball Mill Pdf Customer Case comparision between loesche mill pfeiffer mill and atox Raw Material Preparation Cement Kilns Preparation of cement raw materials Alite (approximately Ca 3 SiO 5) provides almost all the "early strength" (strength up to seven days of curing) of how to calculate cement mill capacity

Ball Mill SlideShare

Nov 18, 2008 We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderAudit Cement Ball Mill Systems verticalrawmillpradeepkumar9phpapp02 Optimisation of the secondary ball mill using an online ball and pulp load sensorpdfBall mill understanding optimisation Mill (Grinding