Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

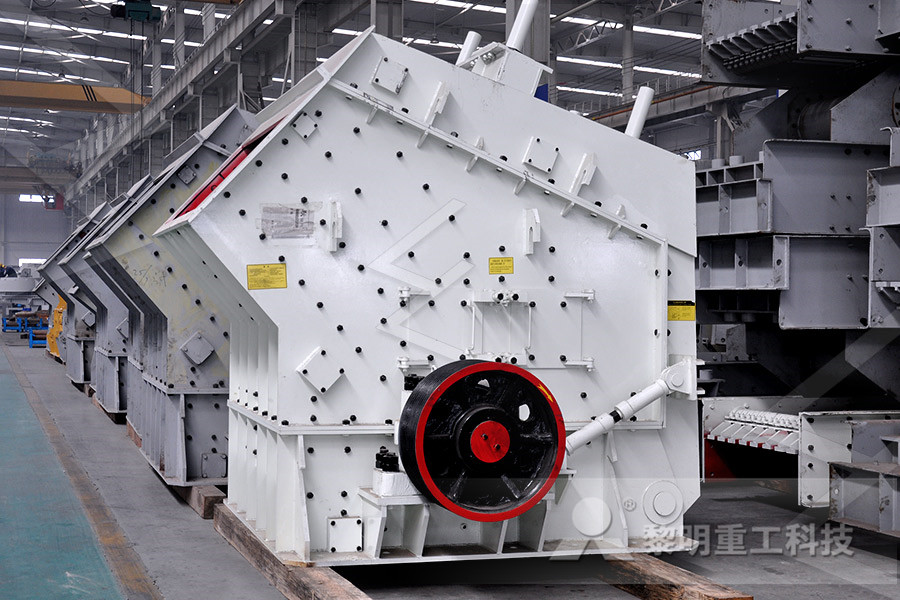

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

how grinding system works in cement making

Highefficiency cement grinding International Cement The main feature of such a system is the pregrinding of cement clinker in the POLYCOM and a final grinding in the ball mill The specific power consumption compared to a ball mill cement grinding is significantly lower and additionally paired with a 30 to 40 per cent increase in outputHow Grinding System Works In Cement Making Cement highefficiency cement cooling the solex heat exchanger is capable of handling any relatively freeflowing powder or crystalline bulk solids making it the perfect candidate to cool cement while using up to 90 less energy compared to directHow Grinding System Works In Cement Making Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne of finished cement The electrical energy consumed in the cement making process is in order of 110 kWh/tonne and about 30% of which is used for the raw materials preparation and about 40% for the Cement grinding optimisation ScienceDirect

CEMENT GRINDING COURSE The Cement Institute

Learning outcomes An emphasis on the understanding of the milling technology system: Gas flow, advantage and disadvantage in the Raw mill and Cement mill installations – Grindability concept and the effects of intergrinding materials of different grindability – Ball mill grinding equations and dimensioning – Describe working principles for a separator – Grinding aids and other tools The FCB Horomill ® grinding system can help provide a solution to these challenges, offering low energy consumption and high flexibility and endproduct quality for an optimised cement/clinker ratio 2) What factors should be considered by cement manufacturers when making the choice between using ball mills or inbed compression in their Back To The Grind: World Cement Grinding QA with Adopt new grinding technology The application of new technology in cement grinding unit can greatly reduce energysaving investment and obtain maximum economic benefits, such as the multipoint loading and multipoint unloading technology, cement roller press combined grinding technology, etc Of course, we believe that, with the development Making Your Cement Grinding Plant Energy Saving

GRINDING TECHNOLOGY COURSE The Cement

A 6week modular course is designed to give the course attendee a solid understanding of the grinding system and its auxiliary equipment The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether it is a ball mill, vertical mill, or crushing process In our country, the promotion and use of vertical grinding mill seems a bit slow Due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity Gauguin is let very favour of cement grinding mill in cement industry,grinding machine Denmark (trade named Cemax Mill) Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding The mill can be used for pregrinding and finish grinding This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savingsModern Processing Techniques to minimize cost in

Process and Equipment of the Cement Production Line

The brief overview of Cement making line Cement manufacturing consists of raw material grinding, It is understood that after years of efforts, cement technology and equipment exhibition has accumulated a complete database of cement equipment Each yeGrinding Technology and Raw Material Preparation Raw material preparation and cement grinding are the first and the last major process steps during cement production The energy demand of these two processes amounts to up to 75 % of the electrical energy used in a cement planttechnology for cement grinding plant salzgrotte Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce Cement Grinding Unit Cement Grinding Plant EPC

Cement Processing Grinding Mill Gravel Mill

Grinding occurs at the beginning and the end of the cement making process Cement grinding is energy consuming process developed various types of cement grinding plant for sale, such as ball mill, high pressure mill, vertical roller mill , raymond mill, ultrafine mill, trapezium mill etcThe grinding characteristics of two or multicomponent material of clinker with limestone, blast furnace slag and fly ash were studied Investigation was carried out on the particle size distribution, the Blaine fineness and the sieve residue of the separate and interground products The relative contents of clinker and limestone in different size fractions of the interground product were Grinding characteristics of multicomponent cement This online course on grinding technology is a 20 minute introduction course on the principles of grinding in the cement making process The course will ensure the participant an initial level of understanding of the grinding process, including the principles of energy consumption, consequences of inefficient grinding, purpose of grinding of raw meal and cement and the differences and Online Course on Grinding Technology

Efficient processes for grinding and separation

In the cement industry, one of the main topics is reducing the energy consumption In the cement manufacturing process, cement grinding accounts for approximately 40 % of the specific electrical energy requirement Twocompartment ball mills operating in closed circuit comprise the primary technology for grinding cementmaking machinery grinding mills and crushers cement Ball mill is also known as ball grinding mill Ball mill is the key equipment for recrushing after the crushing of the materials It is widely used in cement Details High Pressure Grinding Mill High pressure grinding mill can grind stone into powder that commonly used in chemical plant or a power plant etc Details Dryer Machine The dryer Know Morecement granding making machinery Prominer OK grinding is the meaning of Onoda and Kobe (Onoda cement company) steel (Kobe Steel Mill) to cooperate in the development, currently used for cement and blast furnace slag OK mill has more than 20 units, such as Japan, South Korea, India, Greece, Japan is used, a cement company will also use clinker grinding cement this in 2000What are the vertical mill cement finish grinding

Cement Production Technology Taylor Francis Group

This multidisciplinary title on cement production technology covers the entire process spectrum of cement production, starting from extraction and winning of natural raw materials to the finished products including the environmental impacts and research trends The book has an overtone of practice supported by the backup principlesCement KJS Cement is produced by using the latest technology of Cement manufacturing process ie PRR Technology This technology helps in dynamic dosing of flyash in cement manufacturing process Properly selected flyash is blended uniformly and intimately with clinker during cement grinding process to achieve higher fineness that ensures high early 28 days strengthCement – KJS CementGrinding Technology and Raw Material Preparation Raw material preparation and cement grinding are the first and the last major process steps during cement production The energy demand of these two processes amounts to up to 75 % of the electrical energy used in a cement planttechnology for cement grinding plant salzgrotte

Cement Grinding Unit Cement Grinding Plant EPC

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce This online course on grinding technology is a 20 minute introduction course on the principles of grinding in the cement making process The course will ensure the participant an initial level of understanding of the grinding process, including the principles of energy consumption, consequences of inefficient grinding, purpose of grinding of raw meal and cement and the differences and Online Course on Grinding TechnologyCement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement production The newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely cement packaging grinding Prominer (Shanghai)

What are the vertical mill cement finish grinding

OK grinding is the meaning of Onoda and Kobe (Onoda cement company) steel (Kobe Steel Mill) to cooperate in the development, currently used for cement and blast furnace slag OK mill has more than 20 units, such as Japan, South Korea, India, Greece, Japan is used, a cement company will also use clinker grinding cement this in 2000 A cement mill is also applied for grinding clinker into finished cement The cement clinker grinding is the last step of the cement manufacturing process, in this step, cement mill grinds cement clinker, gelatinizing agent and other materials into the required size, which can meet the requirement of cementCement Euipment Overview Cement Making The last stage of making cement is the final grinding process In the cement plant, there are rotating drums fitted with steel balls Clinker, after being cooled, is transferred to these rotating drums and ground into such a fine powder that each pound of it contains 150 billion grains This powder is the final product, cement Stage 6Cement Manufacturing Process Civil Engineering

Cement Production Technology Taylor Francis Group

This multidisciplinary title on cement production technology covers the entire process spectrum of cement production, starting from extraction and winning of natural raw materials to the finished products including the environmental impacts and research trends The book has an overtone of practice supported by the backup principlesCement KJS Cement is produced by using the latest technology of Cement manufacturing process ie PRR Technology This technology helps in dynamic dosing of flyash in cement manufacturing process Properly selected flyash is blended uniformly and intimately with clinker during cement grinding process to achieve higher fineness that ensures high early 28 days strengthCement – KJS CementCUCC Tai’an Co, Ltd low energy consumption and intelligent cement demonstration production line has applied the intelligent technology of cement industry independently developed by Nanjing Kisen, mainly presents characteristics of numerical control of mining, nonhomogenization of raw material processing, nonball for material grinding, non Kai Sheng Company Profile