Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

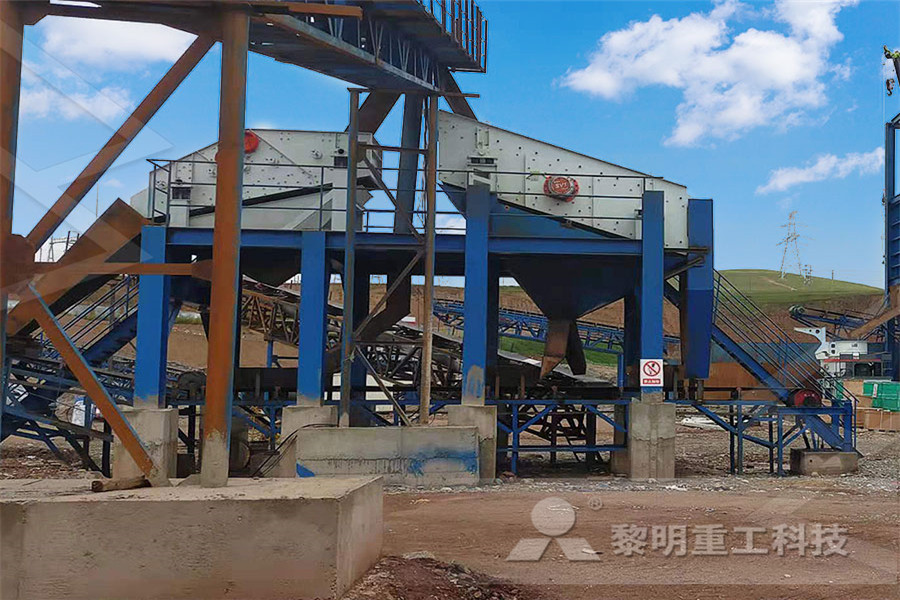

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Modelling of crushing operations in the aggregates industry

The aggregate industry is a very important part of the UK economy Aggregates are used in a variety Simple flowsheet diagram for crushing process 41 Figure 20: Plot showing how the percentage of rock passing 50 mm The overall aim of the European partners is Jan 01, 2015 An aggregate production plant, crushing station, basically involves crushers in series for crushing rocks and screens for classifying and separating fractions measured in size The specifications on the endproducts affect the plant layout including a number of the required crushing stagesAutomatic Feed Rate Control with Feedforward for Crushing Dec 02, 2020 Fine aggregate can be transported to the transit reactor for the next process Secondary crushing and screening The ball mill can be used to grind the fine aggregate again The crushed aggregate is divided into highquality recycled aggregate of 520 mm by secondary screening, which can be used in the concrete manufacturing of C25C30How to Process Sandgravel Aggregate?

Quarrying Process And Quarry Products

Stone quarrying is the multistage process by which rock is extracted from the ground and crushed to produce aggregate, which is then screened into the sizes required for immediate use, or for further processing, such as coating with bitumen to make bituminous macadam (bitmac) or asphaltMore info: mine/case/stonecrushing/aggregates crushing flow chart process Aggregate production line,Aggregate crusher The aggregate proaggregates crushing flow chart process YouTubeHow to Run an Aggregate Crushing Plant? At the same time of economic development, the concrete industry is booming, aggregate sand takes an 80% proportion in all materials of concrete Improving the productivity of aggregate processing plant, which on the sand aggregate manufacturing process put forward higher requirementsAggregate Crushing Plant How to Run a Crushing Plant

Aggregates Processing Crusher,Cone Crusher,Mobile

New Project 150T/H Granite Wet Process Sand Production Line in Middle of China SANME's crusher served the aggregate production line in Argentina SANME exported a cone crusher whose capacity is about 1500 t/h to a mining group ranking at the third place on scale in the worldSep 02, 2019 Virgin or natural stone processing uses a multistage crushing and screening process for producing defined aggregate sizes from large lumps of rock Such classified final fractions are used as aggregates for concrete, asphalt base, binder and surface course layers in road construction, as well as in building constructionPQ University Lesson 7 Crushing Secondary Breaking Nov 01, 2018 Today, production of aggregate is more frequently managed directly on the tunnel project site The challenge then for tunnelling contractors is the selection and mobilisation of the best equipment for the job Roger Murrow reviews the best of the crushing and screening equipment currently on the international marketCrushing and screening for sustainable excavation

Mining Processes and Land End Use Palm Beach Aggregates

The aggregate mining process involves removing aggregate source materials from different depths of the earth's surface The first eight to ten feet of material, called overburden, is removed using an excavator The next 20 to 25 feet of excavation material is rock material consisting of Sep 26, 2016 Aggregate recycling is a growing business in Europe Guy Woodford reports on the world’s largest wet processing plant for construction and demolition waste built by CDE Global for Velde Pukk The new 300tonnes/hour washing plant for Europe: aggregate recycling booms • Aggregate Research gypsum crushing process description gypsum crushing process description europe grilleco A crusher is a machine designed to reduce large rocks into smaller rocks, gravel Chat Now slag crushing process description gypsum and clinker cement plant process description Gypsum Crushing Process Description Europe gypsum and clinker cement plant gypsum crushing process description europe MCC Machinery

How to Process Sandgravel Aggregate?

Dec 02, 2020 Fine aggregate can be transported to the transit reactor for the next process Secondary crushing and screening The ball mill can be used to grind the fine aggregate again The crushed aggregate is divided into highquality recycled aggregate of 520 mm by secondary screening, which can be used in the concrete manufacturing of C25C30In this article, we focus on the selection of crushing equipment and screening equipment in the aggregate production process Selection of crushing equipment Before choosing the crushing equipment for the aggregate production line, it is necessary to survey and test the raw materials to understand the basic physical and chemical properties Essentials of Process Design for Aggregate Crushing Plant The input capacity of One unit of aggregate production line up to 8001000 TPH, the input size is 015mm Aggregate production line produce construction aggregates widely used for making concrete production The aggregate process consists by progressive stages of crushing, screening, and washing The aggregate production flow:Aggregate crusher processingLIMING Mining and Rock

Aggregate Production Process Cornerstone Aggregates Inc

Aggregate Production Process Our Crushing Plant is now considered the most reliable plant in CALABARZON, specifically Batangas The plant is located at Brgy Lucsuhin, Calatagan, Batangas, Philippines QUARRYING This is an essentials stage in the production process, because the quality of the aggregates produced depends on it This is our with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InCRUSHING SCREENINGCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates various processing methodsCrushing and Screening Handbook

Aggregate Crushing Value Test Procedure And Result

Oct 03, 2019 “Aggregate crushing value is determined by taking a percentage of weight crushed aggregate sample passing through 236 mm IS Sieve divided by weight of aggregate sample taken for test” Aggregate crushing value formula is given below, Aggregate crushing value = (W3 / W) or W3 / (W2 – W1) W1 = Empty weight of cylindrical MeasureConstruction waste refers to the collective name of the muck, waste concrete, waste bricks and other wastes produced in the production activities of people engaged in the demolition, construction, decoration, repair and other construction industriWhat is the construction waste crushing process? QuoraConstruction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregatesAggregates are the most mined materials in the world Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as Construction aggregate Wikipedia

Aggregate Quality Control Stonemont Solutions

Aggregate Quality Control and Process Information Management System StonemontQC is the premier aggregate quality control and process information management system available today StonemontQC is designed for producers of crushed stone, sand and gravel, frac sand, golf sand, lime, and cement and any other construction material that requires EuropeMiddle East Africa; Coarse aggregate crushing production line is the one use crusher as the main equipment Hardness of pebbles, gravel, slag, and other similar materials is relatively large and so as the crushing difficulty Fine aggregate in the mining process should be regularly or on a certain number for alkali mining Aggregates making plant for coarse and fine aggregate aggregate physical properties, and, in particular, gradation (size control) Establishing a stable production process may reduce variability of the product EXTRACTION With the exception of slag and other manufactured aggregates most materials for aggregate production come from bedrock or unconsolidated deposits5 Aggregate Production in

Process In Aggregate Crushing Europe

Europe Auction For Aggregate Crusher Plant Aggregate Crushing Plant For Sale Mobile and Stationary Aggregate crushing plant for sale is mainly used to produce aggregate materials as the acceleration of the urbanization process, people have a large demand for building aggregate so the aggregate crushing plants become and important in general, the working process of aggregate crushing For the fine aggregate preparation process, Liming Heavy Industry often recommend the three stage crushing process First, the vibrating feeder feeds the raw materials into the primary crusher such as jaw crusher, and then conveys it to HPT multicylinder hydraulic cone crusher or HST singlecylinder hydraulic cone crusher for fine crushingFine aggregate preparation processLIMING Mining and Rock The input capacity of One unit of aggregate production line up to 8001000 TPH, the input size is 015mm Aggregate production line produce construction aggregates widely used for making concrete production The aggregate process consists by progressive stages of crushing, screening, and washing The aggregate production flow:Aggregate crusher processingLIMING Mining and Rock

Aggregate Processing and Aggregate Crushing Plant

Jul 20, 2019 Aggregates are granular, inert materials, construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates Aggregates are the most mined material in the world It usually produces by aggregate crushing plantSep 13, 2017 No matter what type of crusher you have in your plant – Jaw, Cone, Impactor or VSI – maintenance will be at the heart of your process If the crusher stops, the process stops Scott Campbell, Weir Minerals comminution aftermarket manager for Europe and North Africa, explains why regular maintenance is essential to your process and successRegular maintenance the key to crusher lifewith a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InCRUSHING SCREENING

Mining Processes and Land End Use Palm Beach Aggregates

The aggregate mining process involves removing aggregate source materials from different depths of the earth's surface The first eight to ten feet of material, called overburden, is removed using an excavator The next 20 to 25 feet of excavation material is rock material consisting of Nov 01, 2018 Today, production of aggregate is more frequently managed directly on the tunnel project site The challenge then for tunnelling contractors is the selection and mobilisation of the best equipment for the job Roger Murrow reviews the best of the crushing and screening equipment currently on the international marketCrushing and screening for sustainable excavationConstruction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregatesAggregates are the most mined materials in the world Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as Construction aggregate Wikipedia

Aggregate Crushing Value Test Procedure And Result

Oct 03, 2019 “Aggregate crushing value is determined by taking a percentage of weight crushed aggregate sample passing through 236 mm IS Sieve divided by weight of aggregate sample taken for test” Aggregate crushing value formula is given below, Aggregate crushing value = (W3 / W) or W3 / (W2 – W1) W1 = Empty weight of cylindrical Measurefollowed by a description of the aggregate production process, chronicling the drilling and blasting, crushing, sifting, cleaning, and stockpiling phases Following this process description the definition of Hot Mix Asphalt (HMA) is given and the characteristics of quality HMA are discussed Next, the HMA production process is discussedA Major Qualifying Report Submitted to the Faculty of The debrisremoved construction waste is sent to the crusher for crushing Generally, it needs to be crushed by 23 stages The crushed materials are transported to the return screening unit through the main conveyor belt equipped on the equipment, which meets the requirements of finished product size to the finished product pile, if it does not meet the requirements, return to the crusher to The construction waste crushing processKefid Machinery

Crushing And Screening Plant Process Flow Video!

ZXC European Type Jaw Crusher PE series jaw crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA Jaw Crusher is of high crushing ratio, larger capacity, welldistributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etcEuropeMiddle East Africa; Coarse aggregate crushing production line is the one use crusher as the main equipment Hardness of pebbles, gravel, slag, and other similar materials is relatively large and so as the crushing difficulty Fine aggregate in the mining process should be regularly or on a certain number for alkali mining Aggregates making plant for coarse and fine aggregate