Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

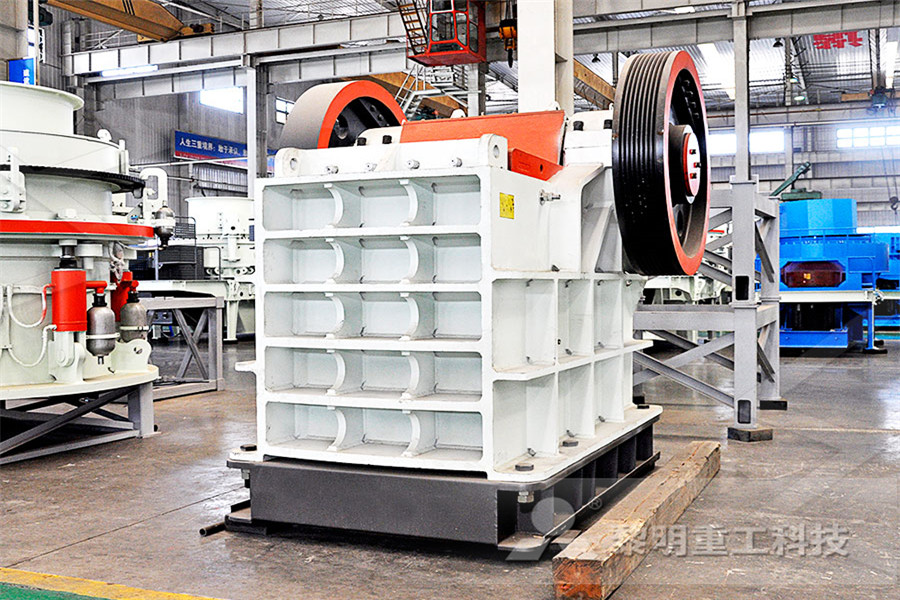

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cylindrical Grinding on a surface grinder YouTube

May 30, 2017 Cylindrical grinding in the surface grinder We try out the ATCO electric centers for grinding the OD of some hardened drill bushings on a tapered mandrel TCylindrical grinding denotes the grinding of a cylindrical surface Usually, “Cylindrical grinding” refers to external cylindrical grinding and the term “internal grinding” is used for internal cylindrical grinding Another form of cylindrical grinding is conical grinding or grinding tapered workpiecesHow to Use a Surface Grinder MachineCylindrical, Centerless, Surface and Honing Grinding HH Arnold Co Cylindrical, Centerless, Surface and Honing Grinding For over 60 years at HH Arnold, we have specialized in providing our customers with a singlesource solution for precision cylindrical grinding and machiningCylindrical, Centerless, Surface and Honing Grinding HH

What is Cylindrical grinding? precisionsurface

In internal cylindrical oscillation grinding, a radial infeed is performed first, followed by the oscillation movement, since the surface to be ground is usually narrower than the internal grinding wheelSurface and Cylindrical Grinding Services Offering surface and cylindrical grinding for an array of intended applications, including die work, Precision Machine Company, Inc works with molds, slabs, turbine blades, and wire form parts We can achieve a maximum surface grinding width of 8 inches and up to 24 inches in lengthSurface and Cylindrical Grinding Services Richmond, VirginiaThe applications of Surface Grinding Machine are as follows It is useful for the grinding of various tools and cutters It is used to finish flat surfaces and cylindrical surfaces Abrasive milling can be performed on the workpieces It is used in various industries and institutionsSurface Grinding Machine: Definition, Parts, Working

Making a Cylindrical Grinder attachment for the surface

Nov 23, 2020 Making a Cylindrical Grinder attachment for the surface grinder Pt2 (and maybe the cutter grinder) I make all my projects from whatever material I can find,Surface and Cylindrical Grinding JR Gilbert Engineering is a well established manufacturer of a variety of components with over 30 years of engineering experienceSurface and Cylindrical Grinding Gilbert EngineeringMay 30, 2017 Cylindrical grinding in the surface grinder We try out the ATCO electric centers for grinding the OD of some hardened drill bushings on a tapered mandrel TCylindrical Grinding on a surface grinder YouTube

Cylindrical, Centerless, Surface and Honing Grinding HH

1 – Toyoda GL4E100II Cylindrical Grinder with InProcess OD gauging 1 – Shigiya OD/ID grinder 1 – Kellenberger URS125x1000 Hydraulic Universal OD Grinder 4 – Studer S20 OC Universal OD grinders for small parts Grinding – Surface 1 – 2017 Chevalier Smart III H1640 16 x 40 Surface GrinderCylindrical grinding denotes the grinding of a cylindrical surface Usually, “Cylindrical grinding” refers to external cylindrical grinding and the term “internal grinding” is used for internal cylindrical grinding Another form of cylindrical grinding is conical grinding or grinding tapered workpiecesHow to Use a Surface Grinder MachineOffering surface and cylindrical grinding for an array of intended applications, including die work, Precision Machine Company, Inc works with molds, slabs, turbine blades, and wire form parts We can achieve a maximum surface grinding width of 8 inches and up to 24 inches in lengthSurface and Cylindrical Grinding Services Richmond, Virginia

What is Cylindrical grinding? precisionsurface

For external cylindrical grinding, long, heavy or thin workpieces must be additionally supported by steady rests so that the necessary form and geometry requirements can be met In the series production of tools like: drills, cutters, step drills, peel grinding is increasingly used surface grinders with rotary tables and horizontal The applications of Surface Grinding Machine are as follows It is useful for the grinding of various tools and cutters It is used to finish flat surfaces and cylindrical surfaces Abrasive milling can be performed on the workpieces It is used in various industries and institutionsSurface Grinding Machine: Definition, Parts, Working Cylindrical Grinders The 2 axes grinder offer easy operations for accurate plunging, traverse grinding, taper and radius grinding operations 2Axis Plunge In Wheelhead The Double Column Surface Grinders offer work table sizes from 40” x 80” to 60” x 240” These large, heavyduty fixedbeam surface grinders are well Surface Grinders Sharp Industries Inc

Making a Cylindrical Grinder attachment for the surface

Nov 23, 2020 Making a Cylindrical Grinder attachment for the surface grinder Pt2 (and maybe the cutter grinder) I make all my projects from whatever material I can find,JR Gilbert Engineering is a well established manufacturer of a variety of components with over 30 years of engineering experience As well as our milling, lathes and Gear cutting facilities we also provide Surface and Cylindrical grinding, allowing us not only to not only provide finish grinding on precision items but also make components complete from material billet to finished Surface and Cylindrical Grinding Gilbert EngineeringNov 28, 2019 322 Geometric accuracy of the grinding machine Cylindrical grinders, internal grinders, and surface grinders, the spindle precision of the machine tool grinding wheel, the accuracy and stability of the feed system, the rigidity and vibration resistance of the whole machine tool are closely related to the surface roughness3 Factors Affecting The Surface Roughness of Grinding

Chapter 17: Grinding Methods and Machines Cutting Tool

Jun 29, 2020 Grinding machines fall into five categories: surface grinders, cylindrical grinders, centerless grinders, internal grinders and specials Surface grinding Surface grinders are used to produce flat, angular and irregular surfaces In the surface grinding process, the grinding wheel revolves on a spindle; and the workpiece, mounted on either a Dec 19, 2018 Dec 19, 2018 A cylindrical grinder is a type of grinding machine that is used to shape the surface of a material Though the name suggests otherwise, cylindrical grinders can work on a variety of shapes, not just cylinders In fact, they can work with any object that has a central axis of rotation such as an ellipse or a crankshaftIndustrial Uses of Cylindrical Grinders Maximum A centerless grinding machine generally refers to a centerless cylindrical grinding machine, that is, the workpiece is not centered or chucked, but the workpiece is ground by the outer circular surface as a positioning surface, and the workpiece is located between the grinding wheel guide wheels and supported by the palletCylindrical Grinder MachineMfg

Universal Cylindrical Grinding Machines Willis Machinery

Available in a variety of configurations manual, automatic and PLC controlled our small cylindrical grinder will be the perfect fit for your grinding application This series of cylindrical grinders has available capacities from 11” – 15” swing and center distances from 16” – Cylindrical Grinders The 2 axes grinder offer easy operations for accurate plunging, traverse grinding, taper and radius grinding operations 2Axis Plunge In Wheelhead The Double Column Surface Grinders offer work table sizes from 40” x 80” to 60” x 240” These large, heavyduty fixedbeam surface grinders Surface Grinders Sharp Industries IncThe applications of Surface Grinding Machine are as follows It is useful for the grinding of various tools and cutters It is used to finish flat surfaces and cylindrical surfaces Abrasive milling can be performed on the workpieces It is used in various industries Surface Grinding Machine: Definition, Parts, Working

Types of Cylindrical grinding machine with Diagram Explained

Universal cylindrical surface grinder External centreless grinder This grinding machine is a production machine in which out side diameter of the workpiece is ground The workpiece is not held between centres but by a work support blade It is rotated by means of a regulating wheel and ground by the grinding Precision Surface and Cylindrical Grinder PI (Physik Instrumente) LP in Nashua NH has an immediate opening for a Precision Grinder for air bearing products This is a full time hourly position, Monday to Friday, day shift only Our ideal candidate will be primarily responsible for precision grinding for air bearing technology and productsPrecision Surface and Cylindrical Grinder Nashua, NHSurface And Cylindrical Grinder anetteideede End surface and cylindrical grinder competitive in high precision and reliable performance welcome to buy the quality, durable and cheap grinding machine made in china from our factory as one of the leading manufacturers and suppliers in china, we alsosurface and cylindrical grinder

±0001mm Ultra Precision Grinding Services Company DEK

We have many years of mold components manufacturing experience, not only has dozens of centerless grinders, cylindrical grinders, and surface grinders, but also has skilled workers, this ensures we can support turning, milling, and precision grinding in our machining shop, and adhering to your specifications to manufacture quality TOOL AND CUTTER GRINDERS #2 Cutter Grinders Monaset – Cutter Grinder CENTERLESS GRINDERS XG – Centerless Grinder XGS – Centerless Grinder MANUAL AND INTERNAL GRINDERS AccuSize – Internal Grinder Twinternal – 2Spindle 5Axis MultiSurface Grinding Center MANUAL AND OD CENTERTYPE AND ROLL GRINDERS Universal and Angle Head Grinders Large Cylindrical Grinders Cincinnati Machines1973 Developed their first generation of Cylindrical Grinders for sale to the marketplace 1981 Developed their first hand feed Surface Grinder, model N612 1982 Introduced larger model (G450) Cylindrical Grinder 1985 Developed Profile Surface GrinderAbout ST – SuperTec USA

Surface grinding Wikipedia

A surface grinder is a machine tool used to provide precision ground surfaces, either to a critical size or for the surface finish The typical precision of a surface grinder depends on the type and usage, however ±0002 mm (±00001 in) should be achievable on most surface grinders wheels are probably the most widely used wheel for surface and cylindrical grinding operations a type 13 saucers b type 1 straight c type 11 flaring cup d type 12 dish b type 1 straight Aluminum oxide and ceramic aluminum oxide wheels are identified by the letter a A b CPrecision Machining Midterm Exam Flashcards QuizletWith the precision grinding process, there are two main types of machine, surface grinding and cylindrical grinding Surface grinding machines consists of a grinding wheel on a revolving horizontal spindle The workpiece is clamped to a moving table and as the workpiece moves past the grinding wheel, an accurate flat surface is produced Grinders for sale – Newmac Equipment

Chapter 17: Grinding Methods and Machines Cutting Tool

Jun 29, 2020 Grinding machines fall into five categories: surface grinders, cylindrical grinders, centerless grinders, internal grinders and specials Surface grinding Surface grinders are used to produce flat, angular and irregular surfaces In the surface grinding process, the grinding wheel revolves on a spindle; and the workpiece, mounted on either a On surface grinder models ranging from the 1632 and smaller, two “V” ways are standard for the cross feed These smaller reciprocating grinder models are saddle type grinding machines and surface and cylindrical grinders Whether you are a multibillion dollar manufacturer or a smaller job shop, Willis Machinery will meet your needs Surface Grinders, Horizontal, Reciprocating Table Willis A centerless grinding machine generally refers to a centerless cylindrical grinding machine, that is, the workpiece is not centered or chucked, but the workpiece is ground by the outer circular surface as a positioning surface, and the workpiece is located between the grinding wheel guide wheels and supported by the palletCylindrical Grinder MachineMfg