Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

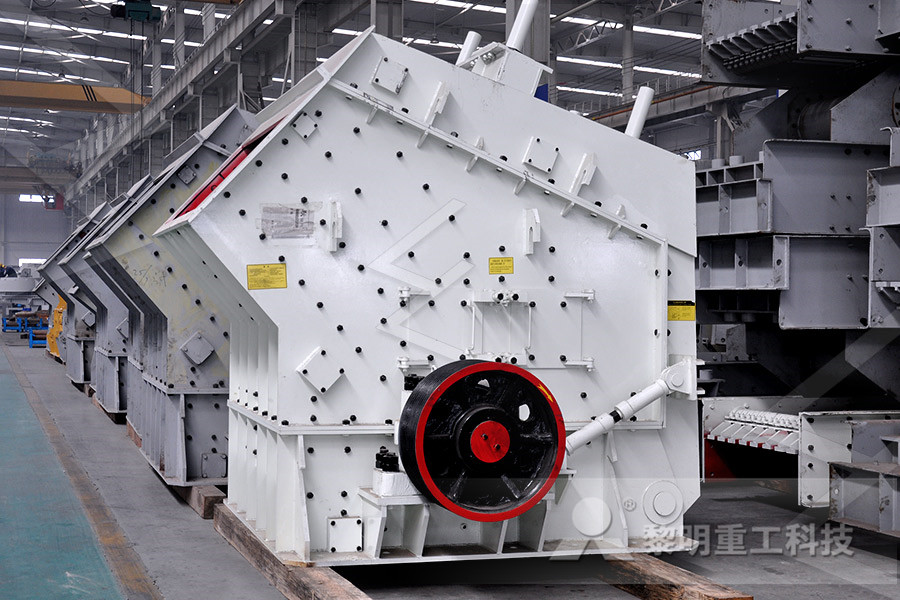

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Primary Crusher an overview ScienceDirect Topics

The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts80mm the Impact Crusher became of significant importance for the cement industry Modern Impact Crusher are equipped with heavy duty rotors in common rail design Specially designed cast discs are combined on one main shaft concentrating the main weight at the circumference of the rotor resulting in a high moment of inertia and kinetic energyOptimized crusher selection for the cement industryIn the cement industry, the HPIH series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain Primary Impactor HPIH

Primary Crushing 911 Metallurgist

Feb 26, 2016 The factors influencing the selection of a crusher for this service are much the same, regardless of how many crushing stages there are in the flowsheet; therefore, the term “primary crusher,” by common usage, is applied to the crusher which takes up the job of reduction where the blasting operations leave offBlake type jaw crusher, primary crushers in the mineral industry; attains maximum amplitude at the bottom of the crushing jaws as the swinging jaw is hinged at the top of the frame These crushers are operated by and controlled by a pitman and a toggle The feed opening is called gape and opening at the discharge end termed as the setAbstract— Keywords IJSERIncreased abrasion and impact resistance of primary and secondary crushers used in cement plants Hardlite, hardplate wear plates and hardfacing welding wires for wear protection and increased lifetime of crusher componentsWear Protection Solutions for Crushers in Cement Plants

Primary And Secondary Crushers In Cement Industry

Primary crushers machine for cement primary and secondary crushers in cement industry, crushers are machines which use a metal surface, mobile primary crushing for cement plant in, more jaw crusher,jaw crushers,primary crushers,jaw breakers, the jaw crusher is used for primary there online chatFeb 26, 2016 The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher Primary Crushing 911 MetallurgistIn the cement industry the grinding path is the critical component for reducing oversize in the process of primary crushing The grinding path of the HPIH series has been significantly improved, with a technicallyadvanced system of hydraulics and mechanics allowing retraction in Primary Impactor HPIH

Primary And Secondary Crushers In Cement Industry

Primary And Secondary Crushers In Cement Industry Cement crusher manufacturer and exporter supertech international however, if the whole cement mining scale is of large size, cone crushers or impact crushers are used to facilitate jaw crushers and act as a secondary or tertiary get quote new line crushing unit for giant keystoneService of LS crusher primary impect ARM done by welding process with LoTherme range of products and get the best service like Orient Cement Ltd +5 pair of Crusher for cement industry131 Blake Type Jaw Crusher Blake type jaw crusher, primary crushers in the mineral industry; attains maximum amplitude at the bottom of the crushing jaws as the swinging jaw is hinged at the top of the frame These crushers are operated by and controlled by a Abstract— Keywords IJSER

Wear Protection Solutions for Crushers in Cement Plants

Increased abrasion and impact resistance of primary and secondary crushers used in cement plants Hardlite, hardplate wear plates and hardfacing welding wires for wear protection and increased lifetime of crusher componentsDescription Lafarge Holcim, one of the world's largest cement producers, put its trust in TH technology for the complete renewal of its primary crushing plant, with the goal of efficiently supplying its cement processing facility in Garraf (Spain)Primary crushing plant for Lafarge Holcim THPrimary crusher Quarry Stockpiles Primary crusher Preblending hall Raw material silos Vertical roller mill Homogenization silo Raw material handling Clinker production Electrostatic precipitator Stack Preheater cement industry cement industry for the cement industry Drive technology for the cement industry

Concrete Crushers, Concrete Pulverizers NPKCE

NPK's Primary/Secondary Concrete Crushers are designed to effectively handle any primary and/or secondary demolition and recycling operation NPK concrete pulverizers easily crush through reinforced concrete and cut through light steel structures allowing material to be separated and recycled, and simultaneously, permits easier handling of materialCement industry in the present scenario is under pressure due to increased competition, rising input costs, lower realisation and reducing profit margins a typical crushing system used to be a two stage crushing with primary crusher in stage 1 (mostly jaw crusher) and hammer crusher in stage 2 This configuration was typically to suit ball Modern Processing Techniques to minimize cost in 8/04 Mineral Products Industry 11192 3 Figure 11192 Figure 111921 Typical stone processing plant Drilling and Blasting SCC30602009, 10 Truck Loading SCC30502033 Haul Roads SCC 3 06 020 11 Truck Unloading and Grizzly Feeder SCC30502031 Primary Crusher SCC 30502001 Secondary Cr usher SCC 30502002 Tertiary CrusherAP42 Section 11192 Crushed Stone Processing and

primary and secondary crushers in cement industry stone

Cement Plant Secondary Crusher Stone Crusher Machine Cement Plant Secondary Crusher Cement Plant Secondary Crusher Stone Crusher Machine Secondary crusher in cement plant A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust In industry crushers are machines which use a metal surface to break or material with primary and secondary crushers Primary crusher options: impact crushers, hammer crushers, sizers impact roll crushers; Generation of a product ideal as feed material for vertical roller mills and ball mills; Consistent high product quality; Cement Industry Mobile/SemiMobile Plant Verify SubmitHazemag Primary Crushing Systems – Hazemag North AmericaEssa JC3000 Jaw Crusher – a heavyduty primary jaw crusher used in sample preparation and Suitable for drill core, rock chip and grab samples, it is the industry standard crusher for the geochemistry laboratory The JC2000 allows for higher crushing capacity than the JC1000, and offers a second dust extraction point and a stronger Laboratory and pilot plant Primary Jaw Crushers

Optimized crusher selection for the cement industry

80mm the Impact Crusher became of significant importance for the cement industry Modern Impact Crusher are equipped with heavy duty rotors in common rail design Specially designed cast discs are combined on one main shaft concentrating the main weight at the circumference of the rotor resulting in a high moment of inertia and kinetic energyThese crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening MPI crushers are extremely versatile machines and have proven their effectiveness in a host of missions like crushing low abrasive materials for quarrying, cement industry, concrete and asphalt recycling, and slag recyclingMEKA CRUSHING SCREENING AND CONCRETE BATCHING Primary crusher Quarry Stockpiles Primary crusher Preblending hall Raw material silos Vertical roller mill Homogenization silo Raw material handling Clinker production Electrostatic precipitator Stack Preheater cement industry cement industry for the cement industry Drive technology for the cement industry

Concrete Crushers, Concrete Pulverizers NPKCE

NPK's Primary/Secondary Concrete Crushers are designed to effectively handle any primary and/or secondary demolition and recycling operation NPK concrete pulverizers easily crush through reinforced concrete and cut through light steel structures allowing material to be separated and recycled, and simultaneously, permits easier handling of materialCement Crusher Manufacturer As a trusted cement crusher manufacturer, every Stedman crusher is engineered for a maximum feed size, target output size, and total capacity, but selecting a crusher on these criteria alone is merely half the task These can be used as a cement crusher, mineral crusherImpact Crusher Cement Crusher Manufacturer Stedman Dec 23, 2015 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26Primary Crusher Selection Design 911 Metallurgist

Rock Aggregate Crushers Stedman Machine Company

Primary crushers are first in a typical size reduction operation Primaries like our MegaSlam™ horizontal shaft impactor are commonly used in the aggregates industry to handle large feed sizes The GrandSlam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand Cement industry in the present scenario is under pressure due to increased competition, rising input costs, lower realisation and reducing profit margins a typical crushing system used to be a two stage crushing with primary crusher in stage 1 (mostly jaw crusher) and hammer crusher in stage 2 This configuration was typically to suit ball Modern Processing Techniques to minimize cost in The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics

Rock Crusher Eastman Rock Crusher

In mining industry, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations Metallurgy area, use crushers and grinding mills for further reducing the mineal ores so that it’s suitable for next step operationEssa JC3000 Jaw Crusher – a heavyduty primary jaw crusher used in sample preparation and Suitable for drill core, rock chip and grab samples, it is the industry standard crusher for the geochemistry laboratory The JC2000 allows for higher crushing capacity than the JC1000, and offers a second dust extraction point and a stronger Laboratory and pilot plant Primary Jaw CrushersPrimary crusher options: impact crushers, hammer crushers, sizers impact roll crushers; Generation of a product ideal as feed material for vertical roller mills and ball mills; Consistent high product quality; Cement Industry Mobile/SemiMobile Plant Verify SubmitHazemag Primary Crushing Systems – Hazemag North America

compression crusher technology for mining

As a world class supplier of crushing equipment for the mining, cement and aggregate industries, we offer crushing products and technology with proven names like FullerTraylor, ABON and Buffalo and and are supported by one of the world’s largest crusher reference lists, which includes many “world firsts”cement industry, gaining industry expertise and earning a reputation as a trusted partner in belt conveyor productivity We’ve spent countless hours between the primary crusher and the stockpile, as well as in the secondary crusher, where confined spaces make cleanup challenging, if not impossible FlexSeal is also ideal on belts Your partner in CEMENT Flexco