Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

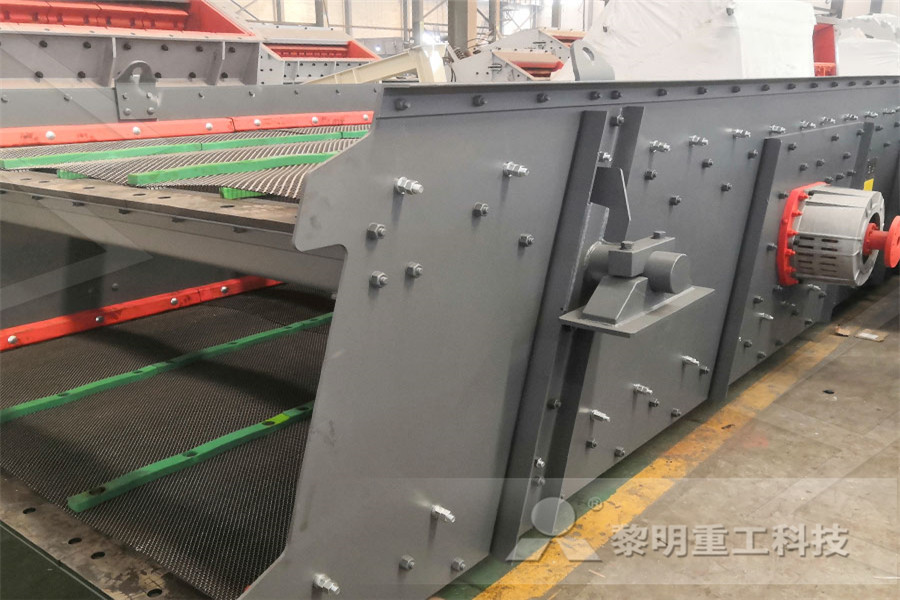

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

silver ore crushing process bacigoeppingende

Small Scale Silver Ore Crushing Process Jaw crusher ball Ore is stockpiled 1 at the processing plant and the process begins by feeding the ore into a hopper with a loader the ore is conveyed and lime is added 2 to raise the ph of the ore following crushing through a jaw crusher 3 the ore is fed into the semi au,Small scale silver ore crushing processCrushing process of silver ore in Gambia Crushing is often divided into three stages, namely, primary crushing, secondary crushing and fine crushing Jaw crusher, gyratory crusher are suitable for primary crushingSilver Ore Crushing Process The recrushing of material from the last two hutches of the coarse jigs to 20 to 25mesh is done in Krupp hall mills which make 30 revolutions per minute and require 8 to 10 hp for motive force The material leaving the ball mill passes through a system of classification at the head of the fine jigs similar to that which took place at the head of the coarse jigsSilver Lead Ore Processing by Roll Crushing Jigging

Silver Ore Crushing Production Line,Silver Ore Crusher

A method called the cyanide, or heap leach, this process has gained acceptance within the mining industry because it is a lowcost way of processing lowergrade silver ores 1 Silver ore is crushed into pieces, usually with 115 in (25375 cm) diameters, to make the material porousSmall Scale Silver Ore Crushing Process Jaw Crusher Ball Ore is stockpiled 1 at the processing plant and the process begins by feeding the ore into a hopper with a loader the ore is conveyed and lime is added 2 to raise the ph of the ore following crushing through a jaw crusher 3 the ore is fed into the semi ausmall scale silver ore crushing small scale silver ore crushing process SmartTech Silver mining process Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching crushers have a very important role in silver ores mining, especially in silver ores’ crushing process The Jaw Crusher is commonly used as the primary crusher and Impact Crusher, Cone Crusher are used as secondary crusherSilver mining equipment, silver crushing and grinding

crushing and screening gold and silver ore

Home › crushing and screening gold and silver ore Heap leachingWikipedia Heap leaching is an industrial mining process used to extract precious metals copper uranium and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials18/12/2016 The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a conducive alkaline conditions for the extractions Moresilver and pper ore crushing kwiatkowskiskorypl These mechanized crushing systems can generate some very significant dust, and so when using them is important to consider methods for dust control or elimination No matter which crushing system you're using, the process will go far Rock Crushing methods and How to recover gold

Silver Ore Crushing Production Line,Silver Ore Crusher

Production Line Silver involved in mixing silver ore, salt, copper sulphide, and water A method called the cyanide, or heap leach, this process has gained acceptance within the mining industry because it is a lowcost way of processing lowergrade silver ores Silver mining process Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching crushers have a very important role in silver ores mining, especially in silver ores’ crushing process The Jaw Crusher is commonly used as the primary crusher and Impact Crusher, Cone Crusher are used as secondary crusherSilver mining equipment, silver crushing and grinding silver ore crusher silver mineral processing process Mar 13, 2018 The process of extracting gold from ore is a multistep one, and the pebbles into other crushing machines to make a powder or slurry Although this process exposes all the gold, the metal is still mixed with a variety of other minerals cyanide solution, the gold and silver in the oreore crushing principles and process

silver and pper ore crushing kwiatkowskiskorypl

18/12/2016 The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a conducive alkaline conditions for the extractions More Preparation of Silver Ore The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a Silver Ore The Mining Processes that Transform Ore *The coarse part of minerals can be recovered by gravity separation The characteristics of silver listed in the table are the technological properties of silver mineral particles in the ore after grinding, that is, the properties that have the greatest impact on the metal recovery process5 Methods of GoldSilver Ore Extraction Mining Pedia

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) process sulfide silver ore without roasting Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment process sulfide silver ore without roasting Mobile Gold Cil Process Yantai Jinpeng Mining Equipment Ore The gold cil process is mainly used in the oxide ore which has low grade of silver its more economize and has more benefit cip plant cip mining cil gold plant cip cil carbon leaching gold ore crushing plant crushing rock for gold gold mine trading cyanidation of gold gold mining techniques cyanide gold leaching mining of ironSilver Ore Crushing Plant EXODUS Mining machine

Rock Crushing methods and How to recover gold

These mechanized crushing systems can generate some very significant dust, and so when using them is important to consider methods for dust control or elimination No matter which crushing system you're using, the process will go far faster, and come out better if you do repeated screenings of the material from time to timeOre processing consists of the following stages crushing and grinding of the ore addition of process water (generally decanted from the tailings pond) to form a slurry Inquiry Online "Aluminium Industry The Silver the crushing of silver ore Cafe Unter den LindenThe Silver Extraction Process The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula (PbAg)S ) and the lead obtained from this oremethods of processing silver ore

Silver Ore The Mining Processes that Transform Ore

Preparation of Silver Ore The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a 18/12/2016 The first stage of mining silver involves the crushing the silver ore to about 115in diameter so as to make the ore porous for the extraction process Once the ore is crushed it is then mixed with lime (about 35 lb per ton) to create a conducive alkaline conditions for the extractions Moresilver and pper ore crushing kwiatkowskiskoryplGold Cil Process Yantai Jinpeng Mining Equipment Ore The gold cil process is mainly used in the oxide ore which has low grade of silver its more economize and has more benefit cip plant cip mining cil gold plant cip cil carbon leaching gold ore crushing plant crushing rock for gold gold mine trading cyanidation of gold gold mining techniques cyanide gold leaching mining of ironSilver Ore Crushing Plant EXODUS Mining machine

when taking crushing a silver ore EURL Berguin

Ore processing consists of the following stages: crushing and grinding of the ore addition of process water (generally decanted from the tailings pond) to form a slurry addition of lime to the ore, and cyanide solution to the slurry, to leach the gold and silver into *The coarse part of minerals can be recovered by gravity separation The characteristics of silver listed in the table are the technological properties of silver mineral particles in the ore after grinding, that is, the properties that have the greatest impact on the metal recovery process5 Methods of GoldSilver Ore Extraction Mining PediaOre crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size There is a balance to keep proper ore size neither too rough (insufficient liberalization) and too fine (overcrushed) in order to achieve high recovery rate and high efficiencyOre Crushing and GrindingOre Beneficiation

silver ore crushing plant inida silver crusher grinding

Ore crusher mining equipmentead and zinc ore mobile rock crusher crushersale zinc ore crushing plant is very popular in south africa, and more and moreet now grinding of zinc ore in the zinc gigsghg,iro ore portable crusher for sale in south africa,chrome lead ore ultrafine grinding mill,extracting silver These mechanized crushing systems can generate some very significant dust, and so when using them is important to consider methods for dust control or elimination No matter which crushing system you're using, the process will go far faster, and come out better if you do repeated screenings of the material from time to timeRock Crushing methods and How to recover gold